Screw conveyors

Back to Conveying

Totally enclosed, spillage-free conveying systems

Our screw conveyors can be delivered as stand-alone units, as part of complete bulk material handling systems or for transportation of processed wood materials.

Their totally-enclosed design delivers an environmentally-friendly profile, ensuring that dust emissions and spillage are eliminated when handling all materials. Our screw conveyors also have low energy consumption demands, further adding to their environmental credentials.

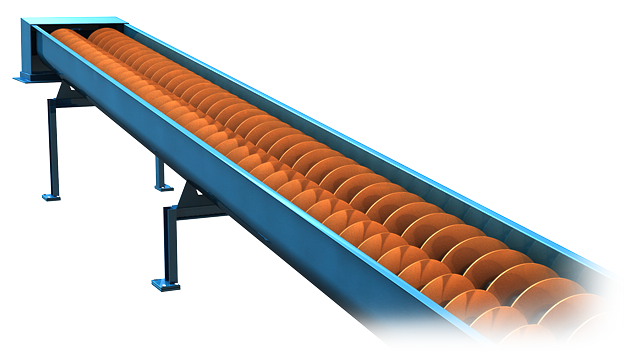

Bruks screw (auger) conveyor

The Bruks screw (auger) conveyor has been specially designed for the continuous, smooth transportation of processed wood materials. The units are particularly well suited for limited spaces requiring the heavy duty transport of material discharged from chippers or mills, such as wood chips, wood pellets, sawdust and shredded bark. Bruks’ screw conveyors meet the needs of numerous applications and are available in a wide range of capacities. Screw diameter and angle of incline, up to 45 degrees, can also be tailored to suit operational requirements.

Long, cost-effective service life

Our screws are commonly used in the discharge area of chippers, smoothing surges that naturally occur due to irregular feeding conditions. A hopper over the screw inlet acts as a surge space, and the volumetric flow of the screw limits the discharge to the correct and steady rate. Screws also collect the sawdust that falls between the feed rollers in waste wood chippers, passing it to the back of the chipper and depositing the sawdust into the collection conveyor, keeping the infeed area free of spillage and mess.

Their intended purpose dictates their specifications such as diameter and flight thickness. All Bruks’ screw conveyors are designed to offer a long service life and the easy replacement of wear parts reduces maintenance requirements to a minimum.

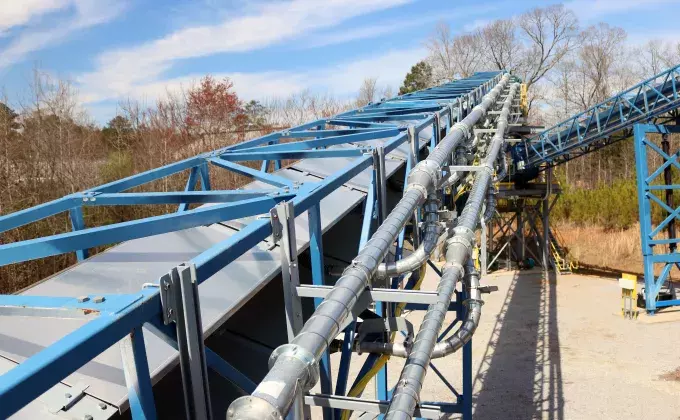

Siwertell screw conveying systems

Our totally-enclosed screw conveyors are ideal for handling powdery, dusty dry bulk materials, especially where scrupulously clean operations are essential. They are lightweight with very small physical footprint, and are available in several diameter sizes to accommodate a wide range of capacities and applications. Siwertell screw conveyors are used in bulk handling ports, terminals, and other shore-based facilities.

Find technical information here

A vertical screw conveyor can elevate material up to 40m. Combining multiple conveyors in a series allows material to be raised to any required height. The same principle holds for horizontal conveyors. Very high capacity operations are achieved by installing two or more screw conveyors alongside each other, served by the same loading box. Vertical screw conveyors require much less space than a bucket elevator, making them ideal when space is limited. The highest capacity for a single vertical screw conveyor is 1,500t/h. Some terminals have complex conveying needs. Siwertell horizontal conveyors can be inclined and are reversible. They can be supplied with multiple inlets and outlets, allowing very flexible cargo distribution arrangements.

Our screw conveyors can handle materials such as cement, lime, ash, clinker, fertilizer, coal, soya beans, grain, gypsum, the screws are continuously improved and we develop different kinds of coatings to prolong the service life of the screw. Every screw is tested and balanced before delivery from our factory to ensure that it arrives in perfect condition.

Our calculations of the new design of a screw conveyor’s long life expectancy have been proven by our customers and the screw with the latest design lasts about two and half to three times longer than previous versions.

The screw conveyors are designed for dust free material transport and are suitable for applications in any kind of indoors and outdoors environment. From small cement and grain dimensions up to enormous coal and clinker screws, we can offer a wide range of screw sizes.

Bruks-Siwertell

Bruks-Siwertell