Conveyors for consistent, efficient and continuous material flows

Bruks Siwertell has one of the most comprehensive ranges of conveyor systems available on the market, from very high-capacity traditional belt and idler conveyor configurations, to totally enclosed robust screw conveyors and state-of-the-art, extremely efficient air-supported, low-friction conveyor system technology.

Our conveying systems ensure the efficient transfer of dry bulk materials around manufacturing plants and port terminal facilities worldwide, including ultra-large power stations that demand some of the largest volumes of material on the planet.

As well as coal, Bruks Siwertell conveyors have been delivered to handle all major and minor dry bulks such as iron ore, grain, bauxite/alumina, phosphate rock, agricultural products, biomass pellets, mineral cargoes, including metal concentrates, cement, and wood and forestry products. Our conveyors can also handle sensitive and volatile cargoes.

Depending on the material’s conveying properties and the type of installation, we offer numerous conveyor system technologies, all with industry-leading innovations, which ensure that our conveyors consistently deliver smooth, safe, continuous material flows for minimal operating and maintenance costs.

VERY HIGH CAPACITY, MINIMIZED INVESTMENT COSTS

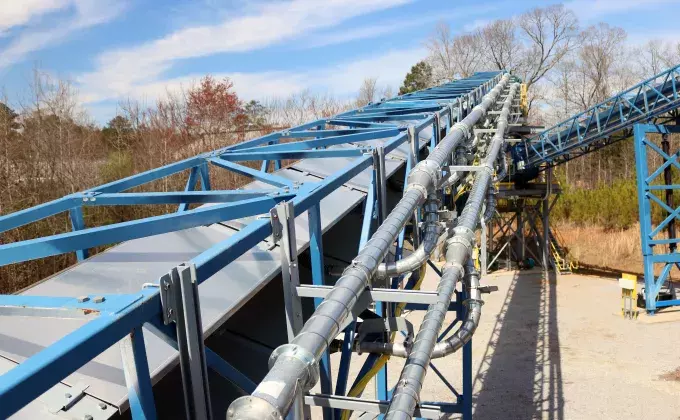

By minimizing dust emissions and energy consumption, Bruks Siwertell conveyors deliver excellent environmental credentials. They are also tailored for their particular operational circumstances, often with modular systems saving both lead and installation times. To cater for different materials and varying capacity requirements, modular belt and idler conveyors can be supplied with belt widths ranging from 1.0m to 2.6m in increments of 0.2m.

Jetty conveyor systems are built up from these standardized modules, which can be inclined where required. The same modules can also be used for conveying systems outside of the port terminal. These high-capacity, environmentally friendly belt conveyors are ideally combined with our large-scale Siwertell ship unloading and loading systems, providing operators with the perfect bulk handling package, all from a single, well-respected source.

Our belt conveyors are typically chosen for materials that have a lower potential for dust creation and are not prone to fluidization. They are also the ideal choice when very high capacities are needed. An important benefit is their minimized investment costs. Combined with excellent reliability and low running costs, they offer both economy and efficiency.

ENCLOSED CONVEYING SYSTEMS ELIMINATE DUST EMISSIONS

We recognize that different innovations and design capabilities, from total containment to space-saving dimensions, are not necessary for all dry bulk cargoes in all circumstances.

When it comes to high-capacity handling of very dusty dry bulk materials, such as cement, in areas where scrupulously clean operations are essential, you cannot beat Bruks Siwertell’s market-leading range of totally enclosed conveyors.

For example, our screw-type conveyor systems are not only enclosed, they have the additional advantage of being lightweight with a small physical footprint. They can also withstand the very abrasive properties of some materials, such as clinker. Screw-type conveying systems deliver consistent, steady conveying velocities, significantly reducing any particle collisions within the conveyor and therefore also minimizing material degradation.

READ MORE ABOUT bulk TERMINals

AIR-SUPPORTED CONVEYING SYSTEMS OFFER COMMERCIAL ADVANTAGES

Our air-supported conveyor systems also offer unique advantages to operators. Bruks Siwertell’s air-supported conveyor range comprises the Tubulator™ and The Belt Conveyor™. Instead of idlers and rollers under a rubberized belt, they both use a pressurized air system. In addition to the significant reduction in maintenance and operational costs, by eliminating rollers, they offer high-capacity conveying with no material degradation and minimal equipment wear.

For low-friction, idler-free conveying in addition to high, long, and potentially steeply inclined installations, Tubulator conveyors are an ideal choice. Because of their structural integrity and significantly reduced weight, Tubulator’s require fewer supports and are easier to install over existing equipment when compared with traditional conveyor frames, and can be installed at considerable heights. Tubulator conveyors are self-supporting up to 25m, and have a free-span of up to 80m when using cable towers, or up to 30m between standard supports.

The Belt Conveyor offers material handling flexibility, and can accommodate higher-density materials using standard belts and standard parts, which reduces costs. It has a simple modular design with a cradle that supports a formed carrying trough and covers. This is the same shape as a 35-degree idler conveyor, so that it still meets industry-standard calculations for the USA’s Conveyors Equipment Manufacturers Association (CEMA).

The belt conveyor & Tubulator

Bruks Siwertell offer two well-proven and patented air supported belt conveyors, The Belt Conveyor and Tubulator. Please click below to learn more about them.

Learn more about The Belt Conveyor

Complete bulk terminal solutions

Bruks Siwertell designs solutions for complete bulk terminals. We will work closely with you to make sure our solutions fit with your specific needs. Our high-capacity, high-efficiency unloaders, loaders, conveying systems and stacking and reclaiming systems stand to provide you with substantial cost savings from reduced operating times.

Bruks-Siwertell

Bruks-Siwertell