Wood processing machines expertly engineered add value to waste wood

As the world shifts to find the best solution for sustainable energy production, it is important that equipment suppliers are able to design systems that best support the use of wood waste to its maximum potential, and make the most of this valuable resource.

Industrial processes often generate byproducts, and many of these hold the potential for onward use, this is particularly true in the processed wood industry. For example, in a sawmill, about 50 percent of the timber volume becomes byproduct. Handling and processing this wood waste, to maximize its yield, is an expert task.

MAXIMIZING TIMBER’S POTENTIAL

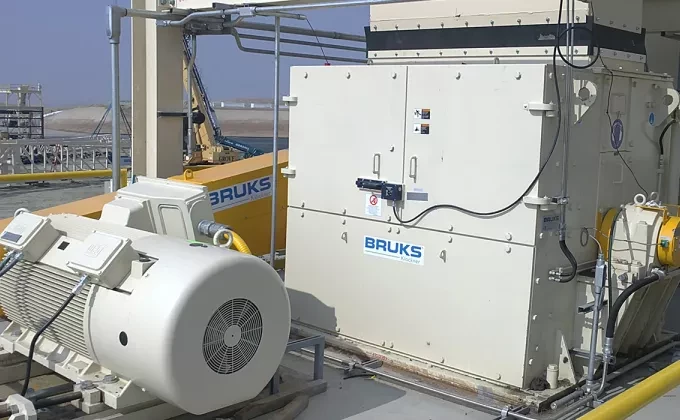

Wood is the material that Bruks Siwertell handles the most of, and its wood-processing machines lead the market. Every part of a tree has value potential. Waste wood residues such as wood chips, bark, hard-to-handle forestry byproducts and end-of-life timber, are no exception, with the biomass, bioenergy and biofuel sectors directly benefitting. However, this potential is only available if the wood-processing technology is there to release it.

Bruks Siwertell designs and delivers a comprehensive range of powerful wood-processing machinery, which has been specifically engineered to process wood waste. This is a continuous development strategy.

POWERFUL HAMMER HOGS SHRED WOOD FIBERS

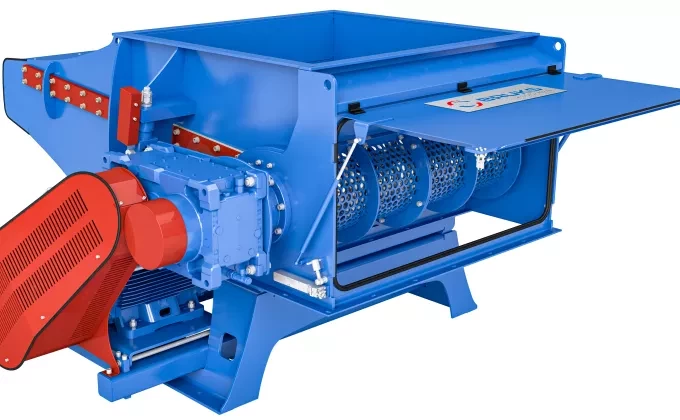

For example, our Rotom hammer hogs feature a two-step size-reduction process to ensure that the end product is no longer waste wood, but effectively a valuable fuel commodity.

Fitted with a unique combination of swinging and fixed hammers, their extremely powerful action makes them the ideal choice for shredding bark, recycling waste wood and other waste timber products.

Developed over decades, our extremely robust, compact hammer hogs offer years of trouble-free operation. They have a modular design, which enables a unit to be perfectly tailored to suit a wide range of wood-processing applications, including various in-feed and rotor configurations.

MACHINES THAT LIVE UP TO THEIR NAME

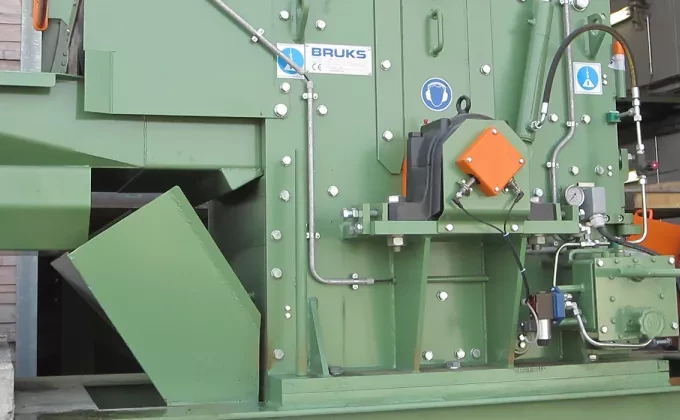

Residue upgraders are wood processing machines that exactly live up to their name and are an invaluable technology when processing waste wood. These wood processing machines are capable of upgrading waste or end-of-life timber to deliver wood chips that can be used for a range of purposes, for example, in the bioenergy market, or recycled back into engineered board or the pulp industry.

They are built to handle a huge variety of wood residues including pallets, particleboard, hard and soft wood waste, bark, medium-density fibreboard (MDF) and oriented strand board (OSB).

Wood waste is delivered into the upgrader via a hydraulically operated pusher, which is guided by large rollers. Both the wood processing machine and its pusher floor use reinforced Hardox, making it extremely durable. For example, with our Bruks Klöckner residue upgrader RU 14-4, a wide-diameter hopper can accommodate large off-cuts, logs, European-sized pallets, single-use pallets and other common pallet sizes. Due to the rotation speeds of the rotor and the geometry of the knives, complete pallets, including packaging items, nails, screws and metal fittings can be shredded. In cases of excessive extraneous material, the machine will automatically stop to avoid damage.

The knife-fixing units are positioned in a milled pocket and the counter-knife is adjustable, meaning that it can be adapted to the degree of wear of the knives without a loss throughput.

Like all our heavy-duty wood-processing machines, safety functions, ease of maintenance, the durability of wear parts and service longevity are critical design elements in our market-leading range hammer hogs and wood residue upgraders.

Bruks-Siwertell

Bruks-Siwertell