An expert eye ensures significant savings

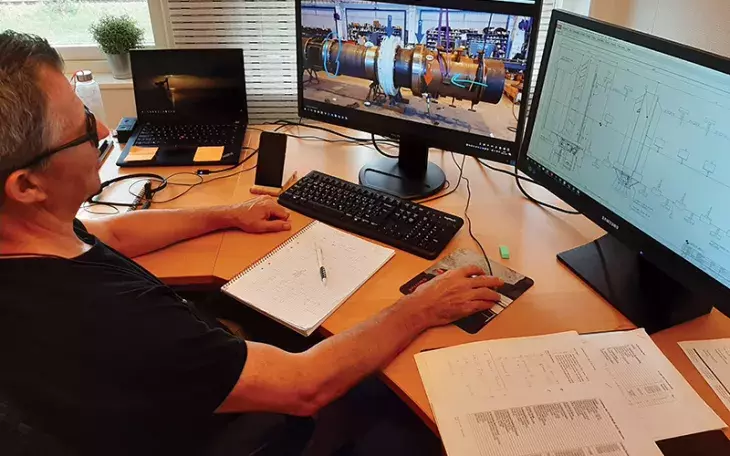

Investment in expert supervision or an inspection will pay you well when it prevents even a short period of downtime.

Equipment performance is improved by ensuring that the machine settings are correct so that the highest possible unloading/loading capacities are maintained. We review the safety of your machine during these visits.

Inspections spot upcoming issues

The purpose of an inspection is to identify problem areas or component damage not detected during regular maintenance, as well as to improve overall operation. Inspections check that wear is following an expected pattern. Any abnormalities are investigated and remedial measures suggested to rectify the problem with minimal impact on availability.

Mechanical and electrical inspections are available based on your needs and the machine’s condition. An inspection report includes comments on each part inspected and describes the need for any special attention, maintenance, repair or upgrade required. It includes recommendations regarding any further investigation or assistance needed from Bruks Siwertell. The report also specifies any training needs.

One-off inspections are available on request and are also offered as part of the service agreement.

Bruks-Siwertell

Bruks-Siwertell