Heavy-duty milling machines engineered for high-quality end products

Bruks Siwertell’s customer-driven industrial milling and grinding systems are specifically designed to add value to wood processing so that owners benefit from higher yields, improved efficiency and equipment’s long, effective service life.

Our high-performance, heavy-duty milling machines are specified to maximize the return on waste wood and can ensure that a wood product is in ideal condition to be processed. Any element that can be enhanced during processing will positively impact efficiency and therefore yield. Even small changes in milling can deliver significant savings and processing advantages.

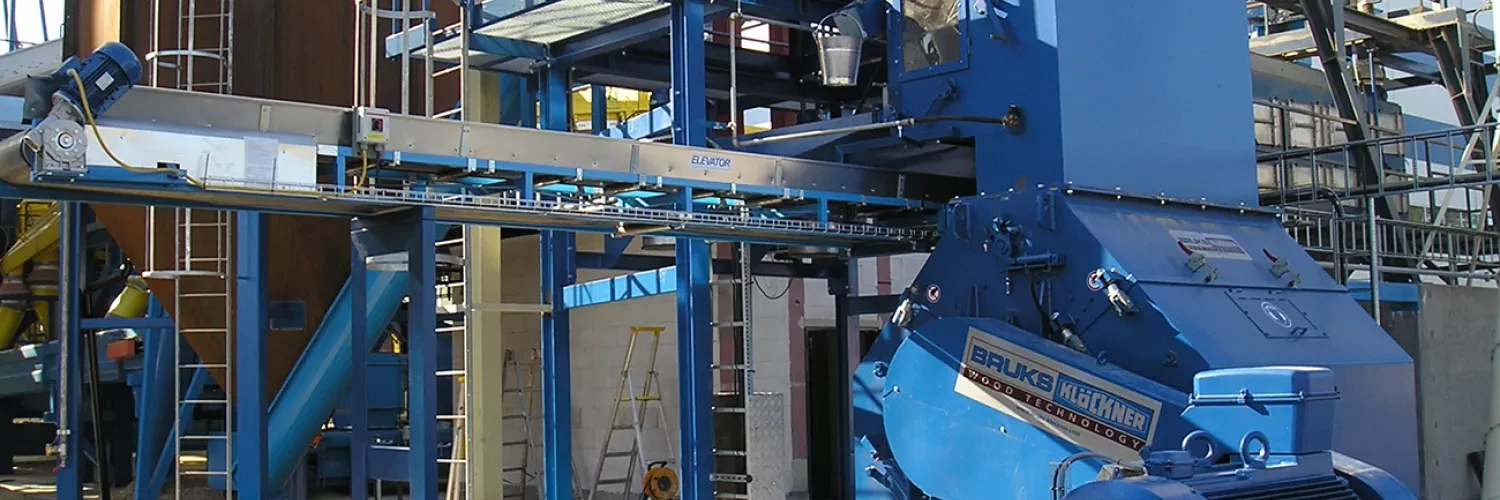

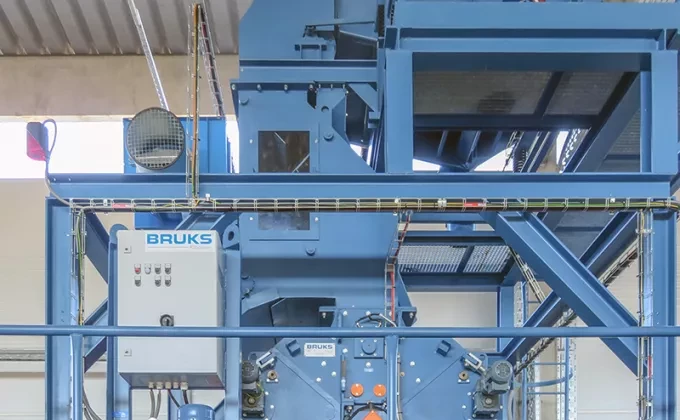

MILLING MACHINES OFFER INDUSTRIAL PROCESSING POWER

Industrial milling machines are one the first stages in preparing timber for onward processing. These systems have to be some of the toughest on the market, capable of grinding, cutting and shredding wood efficiently and quickly in machining processes that capitalize on end-of-life lumber, wood resides and hard to handle forestry waste.

Suitable for processing both green and dry softwoods and hardwoods, as well as a variety of lengths and thicknesses, Bruks Siwertell’s market-leading milling machines offer the processed wood industry reliable, safe and efficient equipment with proven designs and our commitment to ongoing service and maintenance support.

Each milling and industrial grinder machine has been developed for a specific wood-processing task, so that the processed wood is in a more desirable form, depending on end use.

For example, full length trees arriving at a sawmill benefit from being processed by a Bruks butt-flare reducer. This milling machine grinds off the wider, lower part of a tree, which makes it a more uniform shape for further processing and also removes any debris caught in the base, which can damage machinery downstream. Uniform logs can then be processed more quickly by advanced scanning and cutting systems in sawmills and wood waste is minimized. Butt-flare reduction significantly improves processing yields in sawmills.

NO WOOD IS WASTE WOOD

No part of a tree is wasted. Machined offcuts, residues and forestry waste can be further processed in milling systems designed to reduce the size of wood particles even more. Bruks high-capacity hammer mills are used for green and dry wood grinding. For higher water-content, green wood products, our industrial grinder machines have been specially designed to handle the increased moisture.

They have a heavy-duty construction, which powerfully shreds and grinds waste wood materials into valuable fiber. A series of articulated ‘hammers’ are fixed to a rotating drum. These spin against perforated milling segments, which screen the smaller desired particles, allowing them to pass through the machine. They are now an important raw commodity for the particle board industry, pellet production and other biofuel producers.

Other processed wood facilities require larger flakes of wood such as the production of top-quality particle boards as well as other engineered wood boards including fine layer chipboards. In these facilities, industrial milling machines such as our high-performance knife ring flakers are an essential component. These milling machines can produce high-quality flat flakes with thickness from 0.3mm.

We are very used to working closely with operators to find the perfect combination of milling and grinding machines designed to suit their required volumes and processing capacity. Milling machines can be delivered as standalone units or as part of a system solution. Some equipment is configured to be a combination milling machine. Tools can be exchanged and, for example, a knife-ring flaker can be used as a beating flaker and a refining mill. We work with operators to find the most cost-effective milling machine for the job.

Bruks-Siwertell

Bruks-Siwertell