Hammer mill (dry materials)

Back to Grinding & Milling

Industry-leading capacities coupled with high-quality fibers.

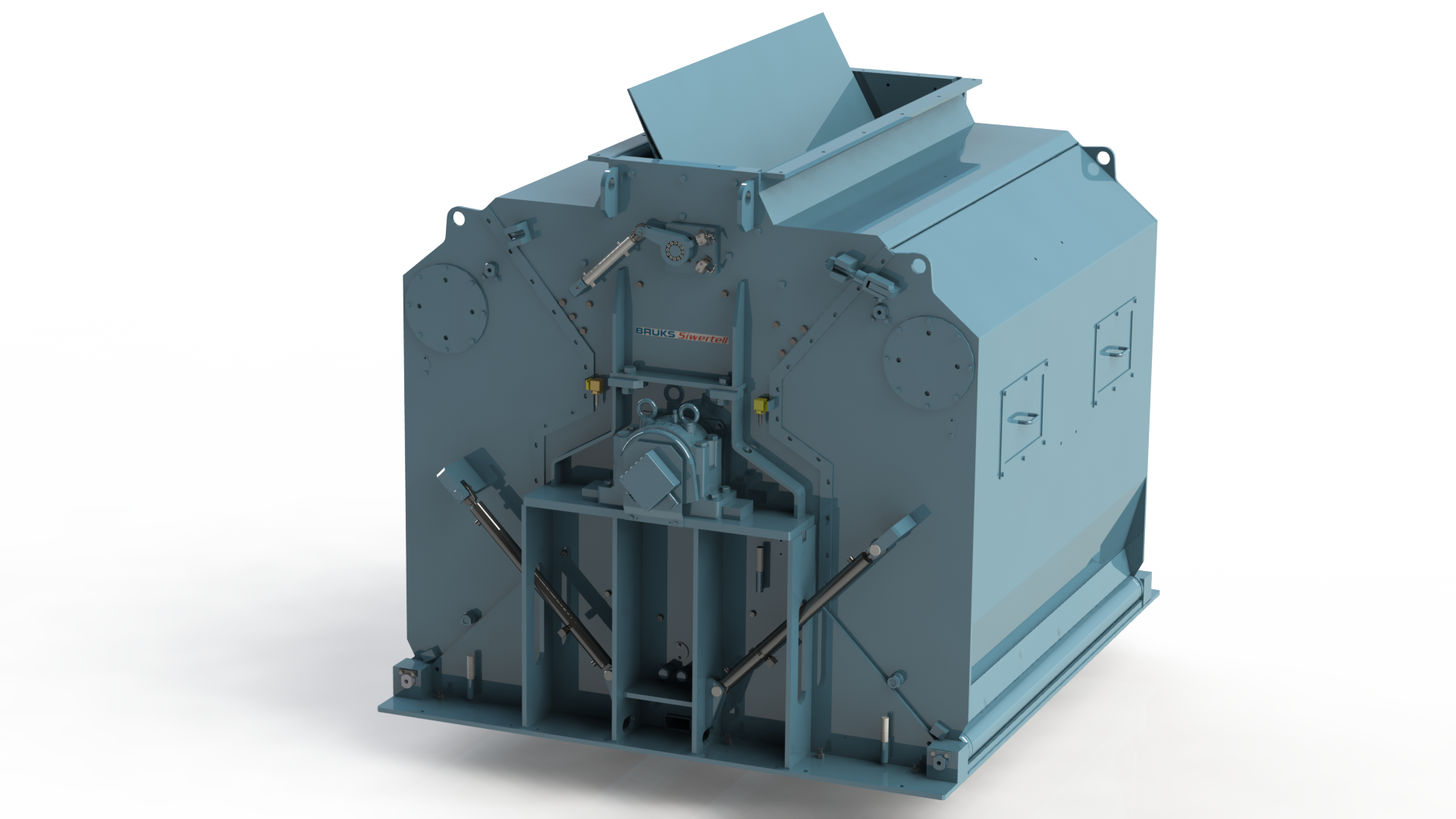

Decades of development and customer-oriented advances have made our hammer mills one of the most effective pieces of technology in the wood-processing industry. They deliver consistently high capacities and are ideal for dry wood grinding, generating valuable wood products for the particle board industry and other wood composite markets, pellet production, briquetting, and boiler fuels.

Bruks’ dry wood hammer mills share many features of our green wood hammer mill units, including those that ensure their low maintenance costs. They use highly-robust, low wear beaters and milling segments. Also, the counter-clockwise and clockwise rotation of the hammer mill means that it is not necessary to turn them or the screens and milling segments to ensure an even wear pattern, which further adds to a reduced maintenance profile.

Easy access to all machinery parts

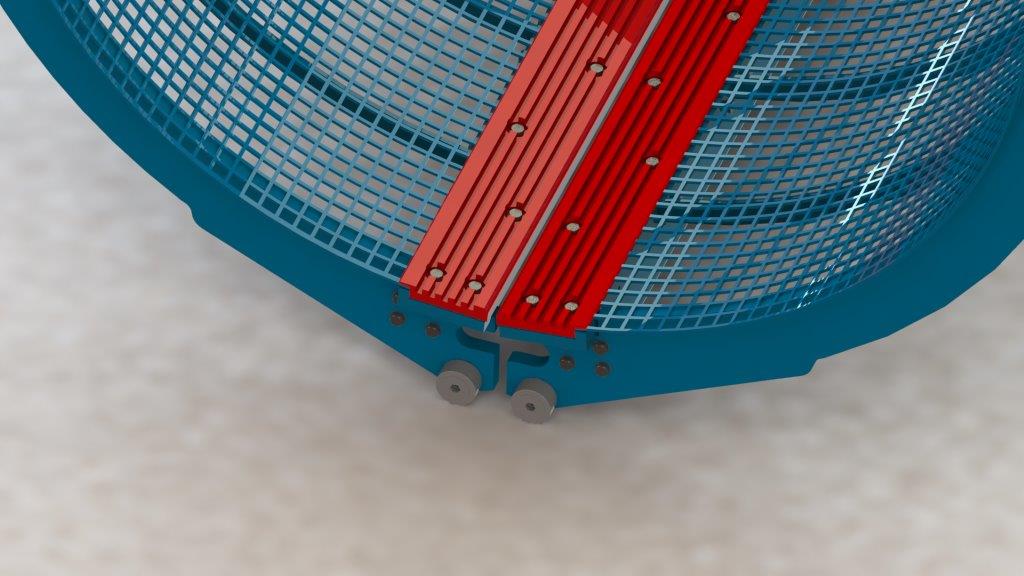

As and when servicing is required, our hammer mills are highly accessible. Screens are held securely in position, clamped by bolted milling segments and both of the lateral housing parts, including screens and milling segments can be folded away using hydraulic cylinders. This ensures quick and easy access to all machinery parts and keeps any unnecessary downtime to an absolute minimum.

Safety standards secured

Like their green wood counterparts, our dry wood hammer mills meet the highest international safety standards and are Atex-classified.

Image: The screen is clamped with milling segments

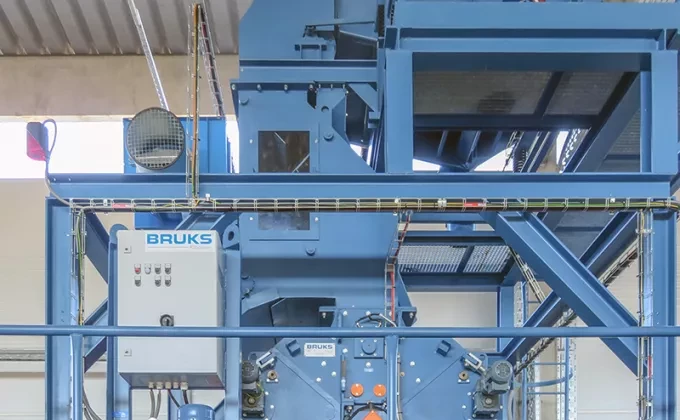

Image: Operating unit for safety and maintenance functions

Technical data

-

Type -

HH 300x850 -

Rotor Diam. [mm] -

700 -

Infeed Opening [mm] -

300 x 850 -

Nr. of Hammers [pcs.] -

144 -

Screening Surface [m²] -

1,2 -

CA [t/h]* -

2 - 4 -

Motor Power [kW] -

75 - 110 -

Wt. [kg]** -

1 400

-

Type -

HH 300x1.200 -

Rotor Diam. [mm] -

700 -

Infeed Opening [mm] -

300 x 1.200 -

Nr. of Hammers [pcs.] -

216 -

Screening Surface [m²] -

1,6 -

CA [t/h]* -

3 - 6 -

Motor Power [kW] -

110 - 160 -

Wt. [kg]** -

1 600

-

Type -

HH 400x1.500 -

Rotor Diam. [mm] -

1 000 -

Infeed Opening [mm] -

400 x 1.500 -

Nr. of Hammers [pcs.] -

216 -

Screening Surface [m²] -

2,9 -

CA [t/h]* -

5 - 10 -

Motor Power [kW] -

160 - 250 -

Wt. [kg]** -

5 500

-

Type -

HH 500x1.800 -

Rotor Diam. [mm] -

1 300 -

Infeed Opening [mm] -

500 x 1.800 -

Nr. of Hammers [pcs.] -

316 -

Screening Surface [m²] -

4,6 -

CA [t/h]* -

8 - 18 -

Motor Power [kW] -

250 - 400 -

Wt. [kg]** -

9 500

-

Type -

HH 600x2.000 -

Rotor Diam. [mm] -

1 600 -

Infeed Opening [mm] -

600 x 2.000 -

Nr. of Hammers [pcs.] -

480 -

Screening Surface [m²] -

7,6 -

CA [t/h]* -

15 - 25 -

Motor Power [kW] -

400 - 630 -

Wt. [kg]** -

15 000

| Type | Rotor Diam. [mm] | Infeed Opening [mm] | Nr. of Hammers [pcs.] | Screening Surface [m²] | CA [t/h]* | Motor Power [kW] | Wt. [kg]** |

|---|---|---|---|---|---|---|---|

| HH 300x850 | 700 | 300 x 850 | 144 | 1,2 | 2 - 4 | 75 - 110 | 1 400 |

| HH 300x1.200 | 700 | 300 x 1.200 | 216 | 1,6 | 3 - 6 | 110 - 160 | 1 600 |

| HH 400x1.500 | 1 000 | 400 x 1.500 | 216 | 2,9 | 5 - 10 | 160 - 250 | 5 500 |

| HH 500x1.800 | 1 300 | 500 x 1.800 | 316 | 4,6 | 8 - 18 | 250 - 400 | 9 500 |

| HH 600x2.000 | 1 600 | 600 x 2.000 | 480 | 7,6 | 15 - 25 | 400 - 630 | 15 000 |

*Capacity. Depending on kind and dimensions of material, moisture content and screen size

**only hammermill without a motor/cleaning/feeding device

Bruks-Siwertell

Bruks-Siwertell