Butt flare reducer

Back to Grinding & Milling

Butt-flare reducing boosts wood-processing productivity and reliability.

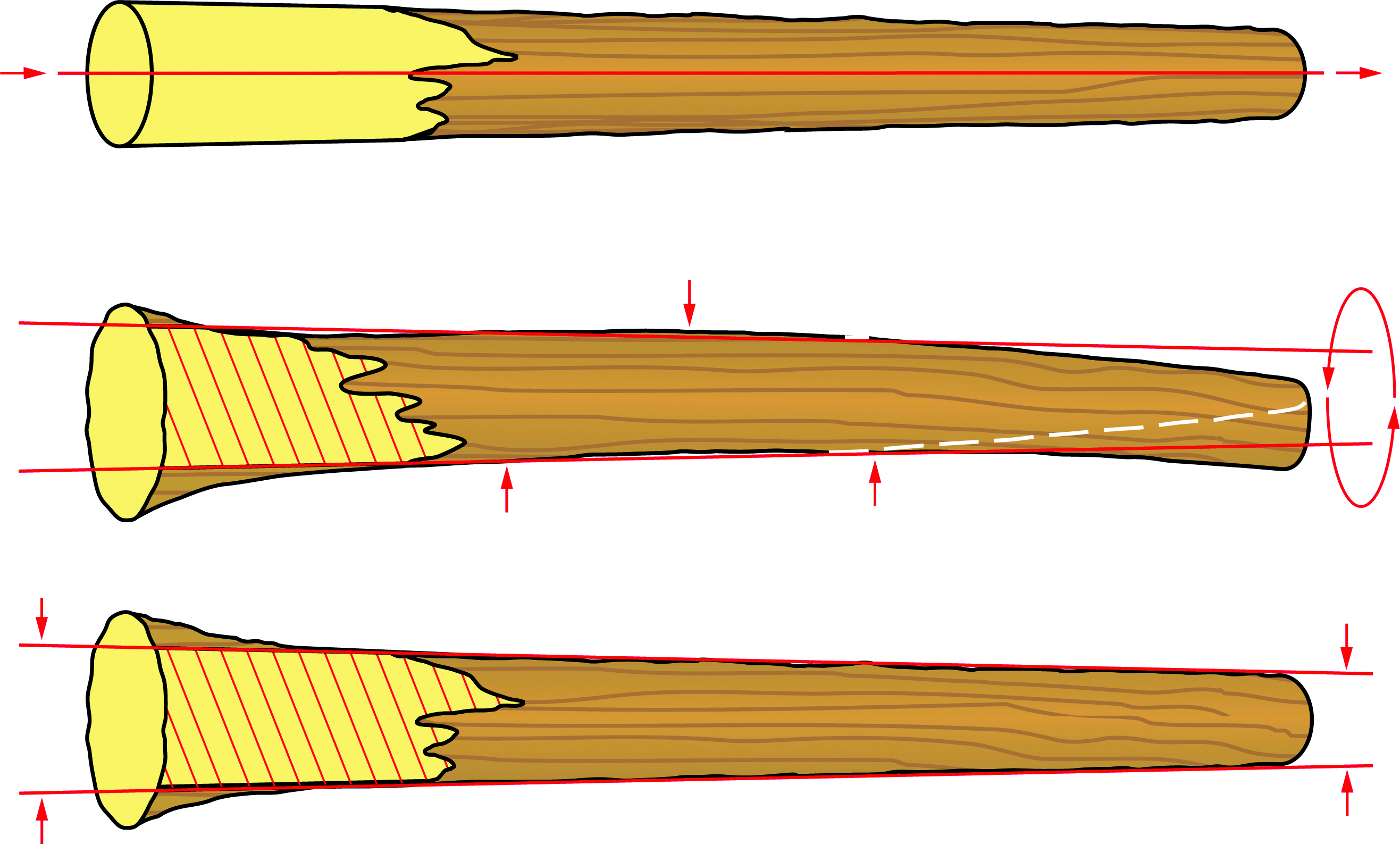

The lowest part of a tree stem expands in diameter as it transitions into the roots. Modern harvesting methods often cut stems close to the ground, thereby including this stem swell in the butt log.

This can cause a problem when processing a log as the flared or swollen end can ‘confuse’ scanning systems. Removing them prior to final scanning can dramatically improve the calculated sawing solution that drives a modern, automated sawmill, improving yield and lumber quality.

The flared butt of a log often has dirt and debris caught up in it that damages machinery, causing unnecessary wear and downtime for wood-processing operations. Regardless of the sawmill size, butt flare reduction significantly increases lumber yields and productivity and the reliability of sawmills, log sorting plants, and veneer mills.

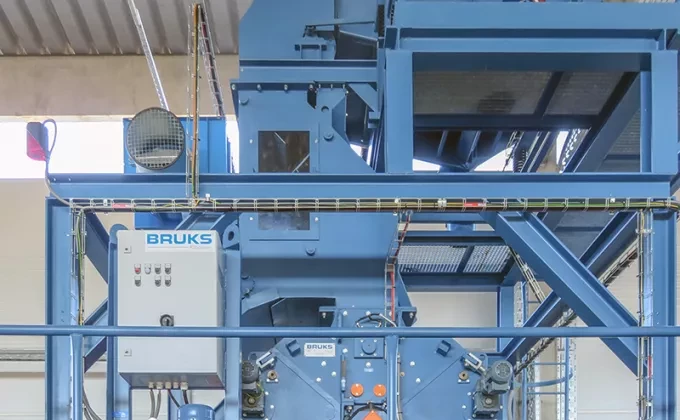

Bruks butt-flare reducers ensure that logs are in excellent condition for onward processing. They reduce the butt flare along the log’s surface line, so that the natural conical form of the log is retained. This permits optimum scanning, aligning and fixing of the log for sawing. Only the protruding root flares are removed, ensuring minimal waste by leaving more material on the log for lumber or chips.

For maximum efficiency, there are no set-up changes for different log diameters and cutting depths are adjustable. Tree-length logs are reduced in the same way as short logs. Machines for tree-length logs have an extended support structure and a reinforced log turning mechanism. The flared end is held firmly by the turning and cutting station while the rest of the log rotates freely in the support blocks.

30 logs a minute

Our butt flare reducer for high-capacity plants can process 30 logs/min or more depending on how it´s implemented in the layout. The control system of the butt flare reducer is essential for the optimization of the reducing process. Information from the log scanner to reduce or to let the log pass through without reducing increases the capacity.

Logs are fed from the side into the reducer’s V-blocks and are positioned with their butt flares above the cutter. Once in place the work cycle is automatically triggered. The hold-down arm lowers and fixes the log in place; the cutter rises up and the toothed chains on V-blocks and the hold-down arm rotate the log while the cutter mills-off the butt flare.

Log rotation is load-controlled and the log is rotated only once. Rotating time is determined individually by an automatic diameter sensor built into the hold-down arm. After reduction, the cutter returns to its idle position, the arm releases the log and the kickers unload it while a signal is given to in-feed the next waiting log.

Cost-efficient solution for small-scale operations

Long logs or short, large diameter or small, we have the right Bruks flare reducer for all requirements. For wood processing plants that need a lower throughput, we manufacture a reducer that can handle logs individually. It has a simplified, cost-efficient design, but can still process logs of all dimensions. Hardwood log processors regularly select this machine as they often individually handle large, misshapen logs. While the throughput rate may be slower, this flare reducer can still process logs up to 900mm diameter.

Special designs for specific tasks

We also manufacture special butt-flare reducer designs. These include machines that not only remove root flares but also protrusions, knots and swellings on other parts of the log. We also have reducers that can process all types of hardwoods.

Optional extras to tailor machines

Bruks Siwertell offers a number of options so that a reducer perfectly meets your needs. For some machine designs we offer two hold-down arm versions: V-shaped arms for larger log dimensions and more log-turning power; and simpler, straight arms for smaller logs.

Tree-length reducers can also be fitted with an end trimming disc, which increases the capacity of the log-handling line by up to 25 percent. Reducing and end-bucking are achieved simultaneously, so when the log moves onto the bucking station, the end cut is no longer needed.

Our optional positioning roller conveyor also delivers processing advantages. Feeding capacity can be maintained even if the logs arrive irregularly on the cross-feeder, as the rollers smoothly align log ends for reducing. The rollers can be mounted in front of or in the machine.

Reducing technique used

The butt flare is reduced along the log´s surface line, thus preserving the natural conic and oval form of the log. This allows for optimum scanning, aligning and fixing of the log for sawing.

The Bruks principle also leaves more material on the log for lumber or chips. Only the troublesome root flares are removed.

Technical data - Butt Flare Reducer

-

Min log length -

3.2m (10.5´), 2,5m (8´) with reduced miling length -

Max log length -

6.2m (20´) standard, tree length models available -

Max log diameter -

900mm (35") -

Milling length -

1320 (52") -

Capacity reducing every log -

14 logs/min (log dia. 200mm/8") -

Capacity reducing every fourth log -

30 logs/min (log dia. 200mm/8") -

Weight -

app. 7 tons

| Min log length | 3.2m (10.5´), 2,5m (8´) with reduced miling length |

|---|---|

| Max log length | 6.2m (20´) standard, tree length models available |

| Max log diameter | 900mm (35") |

| Milling length | 1320 (52") |

| Capacity reducing every log | 14 logs/min (log dia. 200mm/8") |

| Capacity reducing every fourth log | 30 logs/min (log dia. 200mm/8") |

| Weight | app. 7 tons |

Bruks-Siwertell

Bruks-Siwertell