Biofuels

BIOFUEL PRODUCTION EFFICIENCY ENHANCED WITH INDUSTRY-LEADING EQUIPMENT

All organic matter holds stored energy from the sun, even household waste and shredded tires; As we increasingly look to find renewable, sustainable sources of power to meet a global rise in demand, releasing this stored energy through biofuel production and conversion processes comes into sharp focus.

As part of any sustainable biofuel solution, minimizing waste and maximizing biofuel process efficiency is essential; the right technology will deliver the highest energy yields. Bruks Siwertell works closely with operators to ensure this capability and meet biofuel production sustainability requirements through advanced handling and processing equipment. Our solutions support many aspects of the biofuel production chain.

BIOFUEL PRODUCTION: ADVANCES FROM THE FIELD TO THE REFINERY

From the field to the refinery, our wood-processing and dry bulk handling solutions are found throughout the biofuel production industry. Our equipment supports biofuel conversion processes, and is able to efficiently handle and process the huge range of biofuel feedstock materials that come under the biomass umbrella from wood products to agricultural waste.

Cellulose material, essentially fiber found in plant-based biomass material, is a mainstay for biofuel production. Crops are also grown specifically for their biofuel potential including corn, soybeans, sugar cane, rapeseed or canola.

All biomass needs to undergo some degree of processing to maximize the energy that it stores. We have a range of fiber preparation equipment and biofuel conversion technologies, including heavy-duty milling and grinding machines, which are critical components of biofuel production installations. They can process even the most challenging raw materials such as root balls and tree stumps.

In the port, our biofuel expertise continues, as our ship unloading and loading technology supports the global transfer of fiber crops, grains and biomass. They offer some of the market’s highest capacities and minimize material degradation, ensuring that raw materials maintain their quality, essential for efficient biofuel production.

Handling potential energy

All dry bulk biomass products used in the production of biofuels share two main factors: they are required in much larger volumes to generate the equivalent energy produced from fossil fuels; and they have to be more highly processed to release their energy. As a result, biofuel processing and handling equipment must be able to meet the demand for very high capacities and efficiencies. It must also mitigate any safety risks from managing dry bulk biomass materials that naturally hold a lot of energy and can potentially self-combust.

Our equipment is designed to meet these needs with ease, and Siwertell screw-type ship unloaders are the only high-capacity, enclosed, continuous ship unloaders capable of handling biomass safely.

A biofuel handling portfolio

Bruks Siwertell is able to help biofuel producers and biorefineries at every point in their supply chains. Biomass pellets and raw materials for biofuel and biomass production are traded on international and national markets and often transported by barge or larger bulk carriers.

In the port, our Siwertell ship unloaders can continuously discharge grain and soybean biofuels at rated capacities of up to 1,800t/h and our lightweight loaders offer capacities of up to 2,000t/h.

Our wood-processing equipment, milling and grinding machinery, truck dump systems, receiving hoppers, woodyards, storage, and stacking and reclaiming systems further add to our comprehensive range of equipment designed for the biofuel production industry. Our equipment adds value and sustainability at every stage.

Difficult waste wood

End-of-life timber and waste wood residues that no other industry can use are now frequently used in biofuel production and biorefineries. For some, this wood waste can be a challenge to handle, but our biofuel conversion equipment is designed for the task.

Our enclosed disc-scalping screens are often the first-line screen for sorting branches and/or oversized or stringy pieces of different wood-based materials such as chips, sawdust, sawmill waste wood and bark. These heavy-duty machines have decades of proven, reliable operation and are renowned for their durability, safe operation and low maintenance costs.

Sorting out sizes

Our screening systems ensures that operators get the size and quality end products that they need and all unwanted pieces are removed or can be processed further, making onward biofuel processing more efficient. Disc scalping screens are complemented by gyratory freeswinging screens, medium thickness screening, and vibratory screens.

Vibrating conveyors are often specified as part of complex processing facilities and are easily customized to meet different needs. They are frequently paired with Bruks screening systems, and in some cases, they eliminate the need for separate screening units entirely.

Critical conveying systems

Conveying systems play a critical role in biofuel production, feeding raw materials to processing equipment and power-generation facilities. Tailored conveyors are integral to an efficient operation.

We deliver a comprehensive range of conveyors including high-capacity belt systems and specialist air-supported, low-friction conveyors that are capable of transferring many forms of biomass material at very high rates and efficiencies. They also eliminate the use of rollers, which minimizes maintenance and operating costs. Our innovative air-supported conveyor range includes the Tubulator™ and The Belt Conveyor™.

Heavy-duty machinery integral to energy release

Biofuel production is reliant on heavy-duty processing machinery that is able to break down the cellulose fiber ready for onward processing or fermentation. We can offer a range of market-leading milling and grinding machinery, including Bruks and WSM hammer mills, which efficiently process large volumes of wood products, enabling industrial biofuel producers to gain the highest yields from their raw materials.

Hammer mills can be installed as individual units or as a system solution. Our biofuel conversion equipment is configured to meet the unique requirements of each facility and delivers a uniform end product from a diverse range of feedstocks.

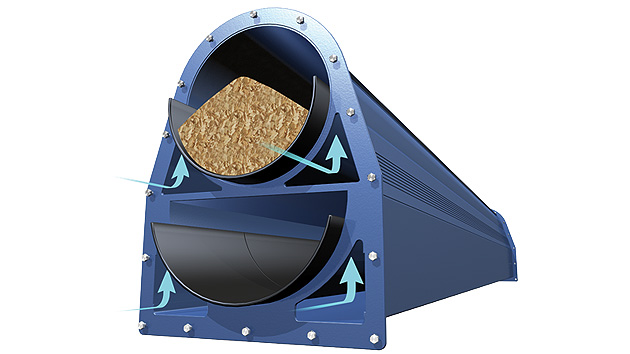

For example, in the grinding chamber of the Bruks hammer mill, waste wood is struck by ganged hammers that rotate at high speeds. It is crushed or shattered between the hammers, screens and grinding bars. The perforated metal screens, which surround the mill’s grinding chamber, retain coarse material for further processing, while allowing the required-sized materials to pass through.

Bruks hammer mills use extremely robust, low wear beaters and milling segments, and because of their alternating counter-clockwise and clockwise rotation it is not necessary to turn them to ensure an even wear pattern, which further adds to a reduced maintenance profile.

Recycling waste wood

Waste wood residue processing machinery is a key element in biofuel production and conversion processes. Our wood-processing technology has been designed specifically to meet the challenges of efficiently handling waste biomass products, from construction and demolition waste wood, to forest slash piles and storm debris.

For example, the WSM Titan grinder can accommodate very large waste wood, such as tree stumps, and is specifically designed with an extremely powerful, heavy-duty chain infeed conveyor and an extra-large pivoting feedroll.

Meanwhile, our Bruks Klöckner Rotom hammer hogs feature a two-step size-reduction process. A unique, powerful combination of swinging and fixed hammers makes them ideal for shredding bark, recycling waste wood and other waste timber products.

WOOD RESIDUE PROCESSING SOLUTIONS

Cutting-edge biofuel plants depend on proven wood-processing technology

As the global demand for renewable energy intensifies, biofuel production plants are being developed and promise the potential of consigning fossil fuels to the past. Part of increasing the sustainable commercialization of the biofuel industry is the growing importance of proven, reliable wood-processing technology, essential in the biofuel conversion process.

Bruks Siwertell references include a delivery to the Norwegian Silva Green Fuel plant. The forest feedstock preparation and storage equipment features a screw-type receiving hopper, raw material screening system with vibrating conveyor, a Bruks hammer mill, storage system, and conveyors to efficiently link all processing sections.

Bruks-Siwertell

Bruks-Siwertell