Panelboard

Panelboard industry technology: Delivering unique capabilities to engineered wood production

The panelboard industry champions the use of end-of-life wood, as well as prime cuts, and is stepping up capacity to meet growing demand for engineered wood products from construction through to furniture manufacture. The panelboard industry is a key timber consumer, focusing production on fiber and particle board and plywood. Veneers and veneered boards also take a share, using high-quality trees to ‘face’ standard lumber.

The ability to produce engineered wood products from what would have been considered waste is not only sustainable, but an excellent business strategy. Furthermore, the panelboard industries have got so good at it that in many cases, its engineered wood products are more practical for their desired use than what nature originally provided. Straighter, cheaper, more stable, and much easier to cut to source in the right lengths, engineered wood has many benefits.

So, what are engineered wood products?

An engineered wood product is essentially a composition of various forms and sizes of wood fibers that undergo different treatments and processes, including compression, glues and resins, to deliver a formed end product that is designed for different purposes, such as beams, sheets and flooring. Free-form components are also classed as an engineered wood product.

Typical examples of engineered wood products include, laminated veneer lumber (LVL) and laminated strand lumber (LSL). Both are incredibly strong, but LVL retains its strength across a single axis because the wood veneers are glued in one direction, whereas LSL is stronger and denser than LVL, as the composite wood strands are placed and compressed at different angles.

Oriented strand board (OSB) also uses wood strands and flakes of wood which are glued and compressed, a similar process is adopted for plywood, but in plywood’s case, a sheet is formed using thin layers of veneers. Like all products, there are varying degrees of quality in the end product.

One of the most well-known engineered wood products is medium density fiberboard (MDF). It is incredibly versatile and comprises processed hardwood and softwood fibers, which are then mixed with binders. Panels are formed through compression and heat exposure. Its applications and uses are vast, from freeform car parts, like dashboards, through to bookcases, and building construction. MDF and OSB are also part of a group of engineered board products called composite boards, or engineered wood. These engineered board products maximize the use of recycled wood materials.

However, it does not mean that just any woodcuts or waste wood will do. Wood fibers need to be long and strong enough to give these materials the structural integrity they require. Bruks Siwertell works closely with customers to ensure that their engineered boards make the best possible use of raw materials.

Panelboard industry: Solutions for mixed-fiber challenges

Sustainability drives and ongoing e-commerce trends are making the wood supply environment highly competitive, where every bit of available fiber is being sought by many different buyers, from the bioenergy, biofuel, and pulp and paper industries through to the panelboard sector for engineered wood products.

This is making wood-processing technology that has the ability to screen, clean, and size what have been traditionally low-value wood sources make the difference between profit and loss in the mill. Bruks Siwertell can offer these capabilities, and operators can choose between or integrate both Bruks and WSM market-leading machinery.

From the WSM portfolio, WSM screening and milling machinery covers disc screens, including the innovative Waterfall™ fine screen, vibrating and oscillating screens, green-side grinders, high-capacity hammermills, and horizontal hogging and grinding systems.

From the moment wood is delivered to the mill, to the point at which it enters the final processing stages, WSM feeders, hoppers, conveyors, screens, and sizing systems have the ability to transform these low-cost raw materials into a consistently sized and clean fiber product perfectly suited to panelboard industry manufacturing processes and the production of engineered wood products.

Uniform fibers turn the biggest profits

Uniform fibers deliver better processing, and effective screening and milling are keys to uniformity. Using the right machinery during fiber preparation has a significant impact on the business as a whole, we can help you make these important decisions from the offset.

WSM horizontal grinding systems and mid-speed shredder systems are ideally suited for processing panel trim and reject panels for the engineered wood product industry. The horizontal feed easily handles long and wide materials, including side and end trim, edgings, veneer trim, and reject panels. They are available in a range of capacities and are used throughout the panelboard industry to reclaim valuable fiber.

We understand that raw materials vary considerably from plant to plant from sawmill residuals, chips, shavings, post-consumer wood waste, or material from sustainably managed forests. However, feedstocks also vary within the facility itself, so wood-processing machinery needs to be matched at each stage of panelboard production to ensure the lowest levels of maintenance and the highest levels of efficiency and reliability.

Panelboard industry: Bringing the pieces together

The engineered board industry relies heavily on robust wood-residue processing equipment including screening systems, chippers, and milling and grinding machinery. From our butt-flare reducers, which remove debris and deliver uniformity to logs, through to Bruks and WSM hammer mills and grinders, Bruks Rotom hammer hogs, and knife-ring flakers, all our equipment is designed to maximize yields and ensure the peak operational performance of any board manufacturing plant.

A cut above the rest

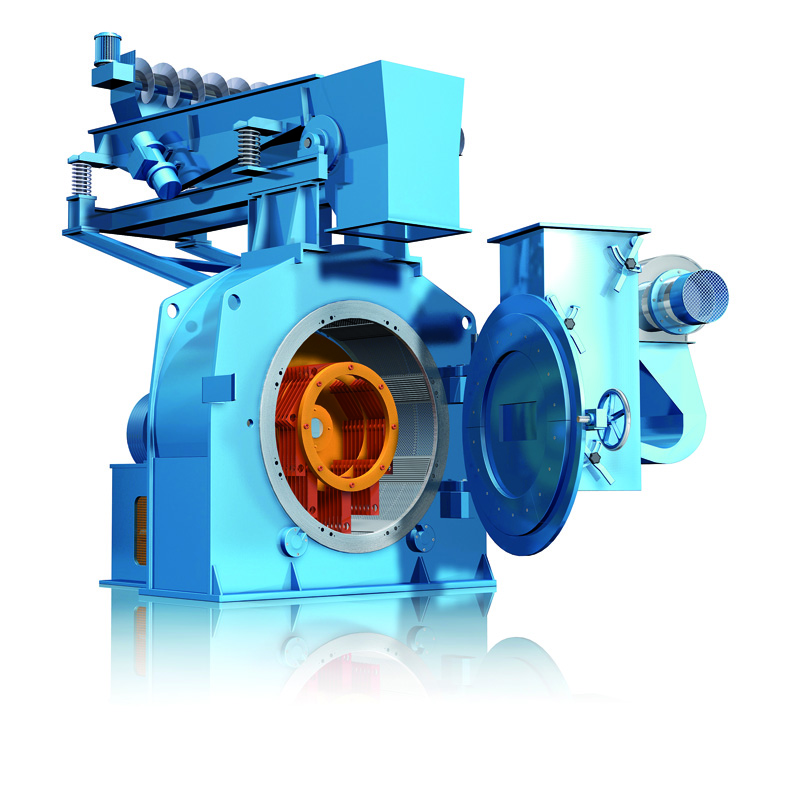

Crucial to many plants in the panelboard industry is the knife-ring flaker, transforming both dry and green timber into wood flakes, which can be compressed and glued together. Bruks knife-ring flakers, with Klöckner flaking systems, set the industry standard. They are optimized to produce high-quality flat flakes with a thickness from 0.3mm, producing a strong, non-porous board.

All our equipment is designed for durability, and our knife-ring flakers feature easily reversible wear components such as beating arms, liners and edges, delivering even wear patterns and more than doubling tool service life.

Minimal maintenance, maximum yields

Bruks hammer mills have served the panelboard industry for decades, ensuring that wood material is broken down and processed into its desired size at consistently high volumes. Our designs also focus on a low-wear operation.

Extremely hard-wearing components and the counter-clockwise and clockwise rotation of the hammer mill means that it is not necessary to turn the beaters or the screens and milling segments to ensure an even wear pattern, reducing maintenance costs.

For larger scale wood-processing requirements, Bruks hammer mills can be delivered as part of a complete system, in which several hammer mills can operate simultaneously in a seamlessly synchronized operation. This is highly energy-efficient and delivers vast volumes of consistently sized processed wood.

Sorting out the sizes

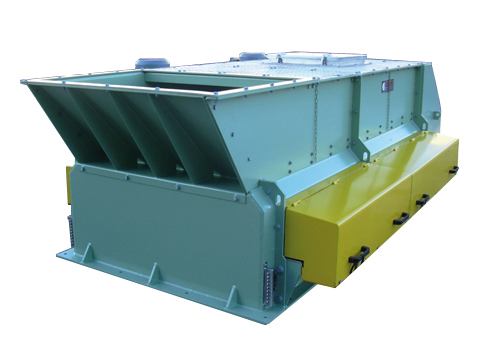

A vital step in many dry bulk material applications, including processed wood, is screening. The particle board and panelboard industries requires a high degree of material consistency, both in terms of size and quality.

Screening is a first-line process and often handled by our disc-scalping screen. It delivers extremely robust and quiet processing, removing branches, oversized timber, or stringy pieces of different wood-based materials such as chips, sawdust, sawmill waste and bark.

Getting the goods

The huge volumes of processed wood used by the engineered board industry puts a heavy focus on conveying and storage and reclaiming systems.

For conveying, Bruks Siwertell has a wide variety of options for handling large volumes of wood chip dry bulk from traditional idler belt conveyors through to air-supported systems. Our modular vibrating conveyors are a popular choice in the panelboard industry, offering an extremely efficient way to transfer and process different sized bulk materials, including larger and longer pieces of processed wood.

Conveying innovation drives down costs

Our innovative range of air-supported, low-friction conveyors include The Belt Conveyor™ and Tubulator™. Using a cushion of pressurized air under the belt to replace rollers, our systems deliver very high capacities, low material degradation rates, and vastly reduced maintenance and operational costs.

High volumes, handled

Getting the most out of available resources underpins the ethos of the panelboard industry; Bruks Siwertell helps operators go that bit further.

This approach extends to our storage and reclaiming solutions as well. Many large-scale wood chip-handling facilities, including biomass pellet plants and paper mills, use a fully-automated Bruks Siwertell stacker reclaimer system, which operates around the clock.

We offer one of the most comprehensive stacker reclaimer portfolios on the market. These can be tailored to meet all the needs of stockyards and storage facilities. You can find out more here.

Controlling dust emissions

Working with wood is inherently dusty and a critical part of all our machinery designs is controlling any dust emissions. This protects the environment and the equipment.

Dust control measures range from advanced infeed receiving hoppers through to low-profile truck dumpers, and dust collectors.

Being a good neighbor

High concentrations of dust from processed wood can cause problems if left unchecked. Aside from its environmental impact, sawdust can build up on the surface of machinery, especially on oiled parts, and interfere with equipment function; it can also potentially increase fire risk or the spread of fires in particularly hot and dry environments.

Bruks Siwertell serves the bulk truck sector and leads the market in both drive-on and back-on truck dumper versions. We have developed many ways to mitigate the dust emissions that invariably occur from this form of material discharge.

Bruks-Siwertell

Bruks-Siwertell