Residue Upgrader RU 14-4

Back to Wood residue processing

Powerful wood waste processing equipment adds value and sustainability

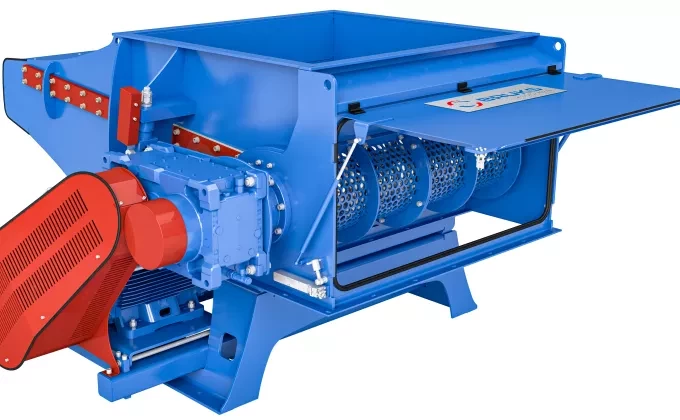

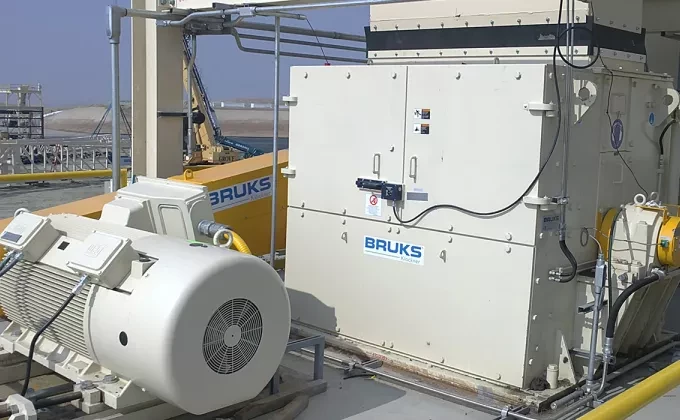

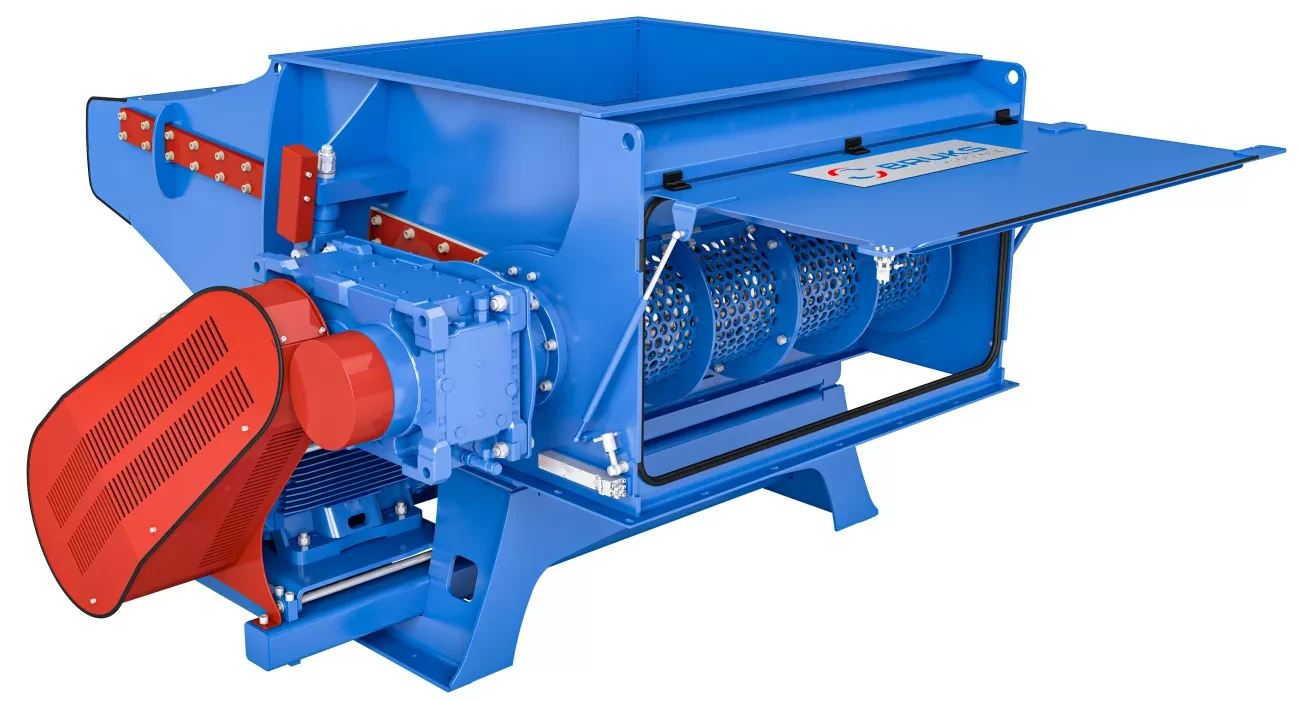

Wood waste processing equipment, such as the Bruks Klöckner residue upgrader RU 14-4, is key for converting wood processing residues into valuable fiber. Our RU 14-4 wood waste processing equipment is capable of performing a wide variety of wood residue processing tasks. The RU 14-4’s outstanding features include its robust construction, high efficiency and the reliable production of consistent quality wood chips from varying feedstocks.

The RU 14-4 specialized wood waste processing equipment is ideal for use across a wide range of applications including the pallet, panelboard and furniture industries, sawmills, carpentry businesses and wood fiber-packaging manufacturing. It ensures that any end-of-life timber is not wasted, but repurposed, maximizing the profitability of an operation and also its sustainability.

The RU 14-4 upgrades waste or end-of-life timber to deliver wood chips that can be used across a number of industrial applications, for example, in the bioenergy market. Input material can include a wide range of wood processing residues pallets, particleboard, hard and soft wood waste, bark, medium-density fiberboard (MDF) and oriented strand board (OSB).

Whole pallets handled with ease

The RU 14-4 has a wide-diameter hopper, which can accommodate large off-cuts, logs, and all common pallet sizes, including single-use types. Our RU 14-4 wood waste processing equipment can withstand smaller-sized extraneous material due to the rotation speeds of the rotor and the geometry of the knives. This means that complete pallets, including packaging items, nails, screws and metal fittings can be shredded. In cases of excessive extraneous material, the machine will automatically stop to avoid damage.

Heavy-duty performance

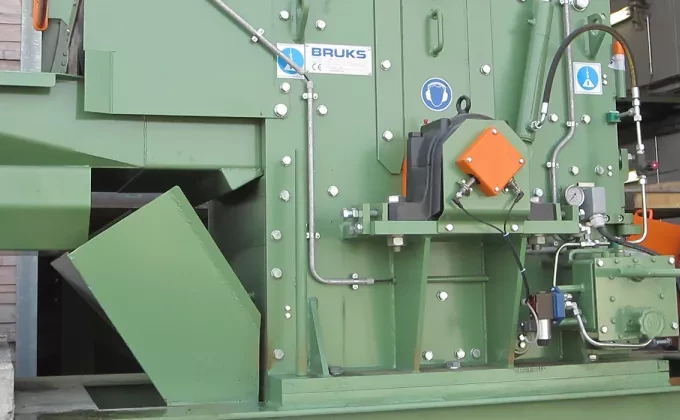

Material is delivered into the unit via a powerful, hydraulically operated pusher with optimized geometry. The pusher is guided by large rollers and its action is dependent on the load entering the machine. Both the machine and its pusher floor make use of reinforced Hardox material, making it extremely durable.

The number and size of the cutting tools, as well as the screen perforations, are dimensioned according to operational requirements and the type of input material handled. The RU 14-4 wood waste processing equipment housing features a user-friendly design, allowing for quick and easy control, including the rotation of cutting tools, counter-knives and screens.

Designed for minimized maintenance

Maintenance costs are minimized through good design and the quality of components, including the wear-resistant steel cutting tool, which can be rotated to even wear patterns and maximize use.

Operational advantages

- Flexible configurations for different operational requirements

- Suitable for use in a wide variety of applications

- High throughput rate

- Consistent end-product regardless of input materials

- Suitable for wet and dry wood material handling

- Solid, quality construction

- Easily maintained

- Able to withstand smaller-sized extraneous material

Wide range of input material accommodated

- Pallets

- Particleboard

- Hard and soft wood waste

- Bark

- Medium-density fibreboard (MDF) panels

- Oriented strand board (OSB)

Industrial applications

- Furniture industry

- Pallet industry

- Carpentry business

- Panelboard industry

- Sawmills

- Wood fiber-packaging industry

Key components

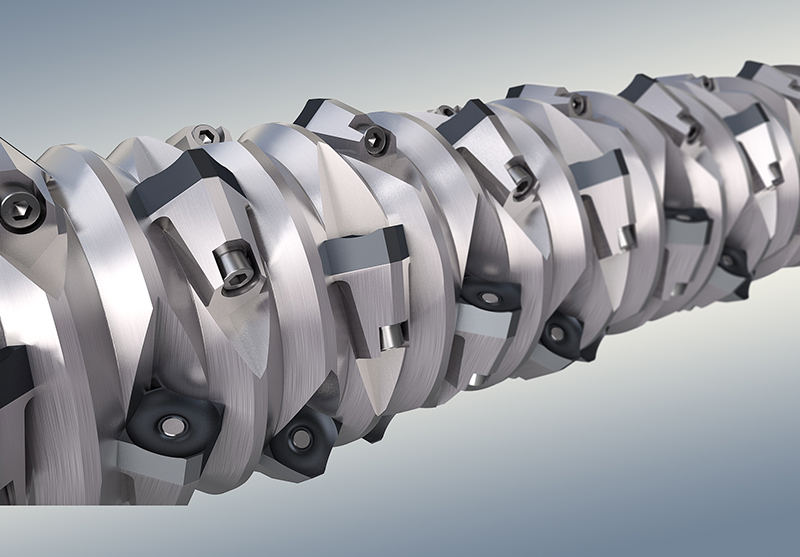

Rotor

Image: Rotor equipped with rotatable cutting tools. Rotor diameters are specified according to requirements.

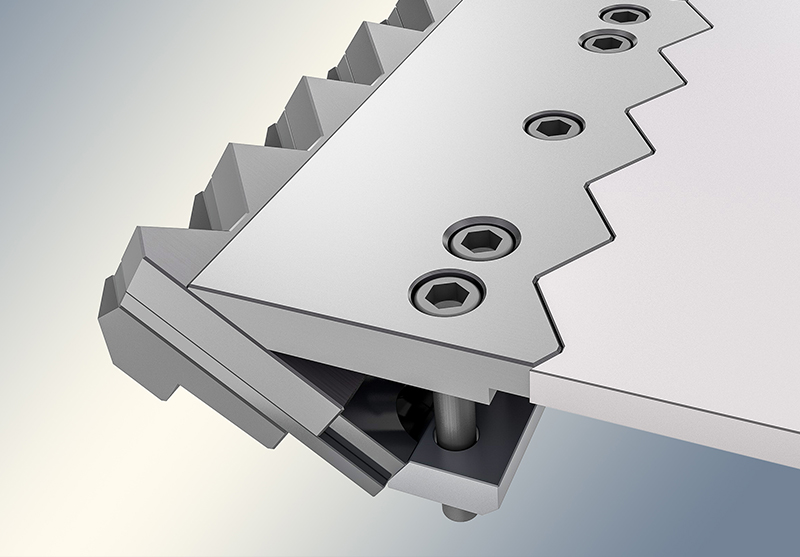

Counter-knife

Image: Clamped counter-knife with segmented sections. Designed according to the required end-product.

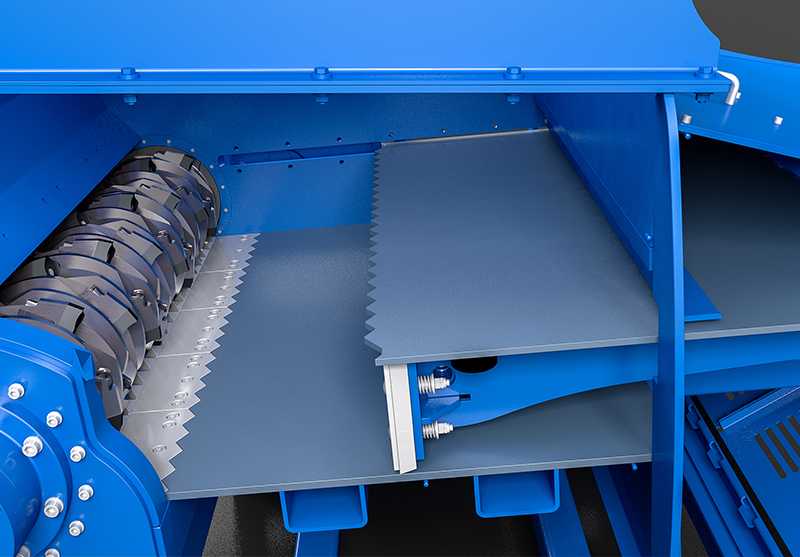

Pusher

Image: The pusher unit moves material close to the rotor, delivering a precise, narrow cutting gap. Both the front and rear sides of the pusher are enclosed.

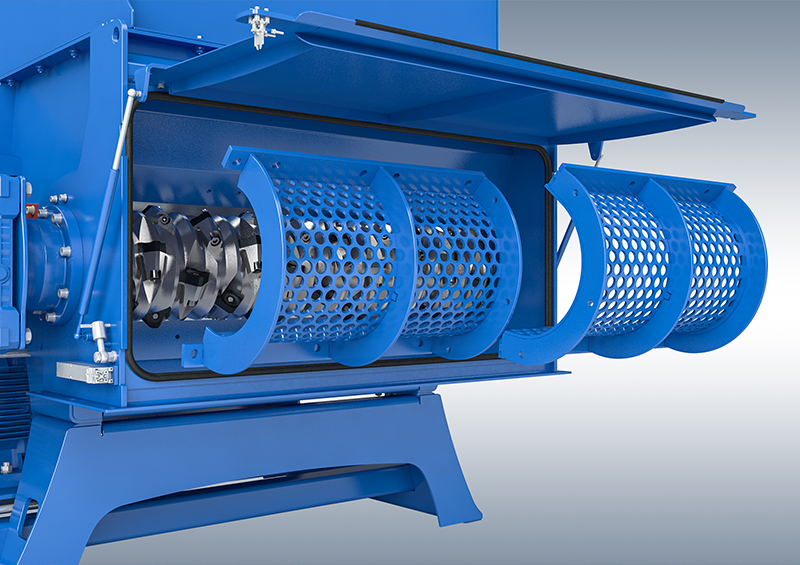

Screen

Image: The screen basket and inserts, which can be rotated, are designed in two parts and held securely in position with clamps. Screen perforations are dimensioned according to the required final product.

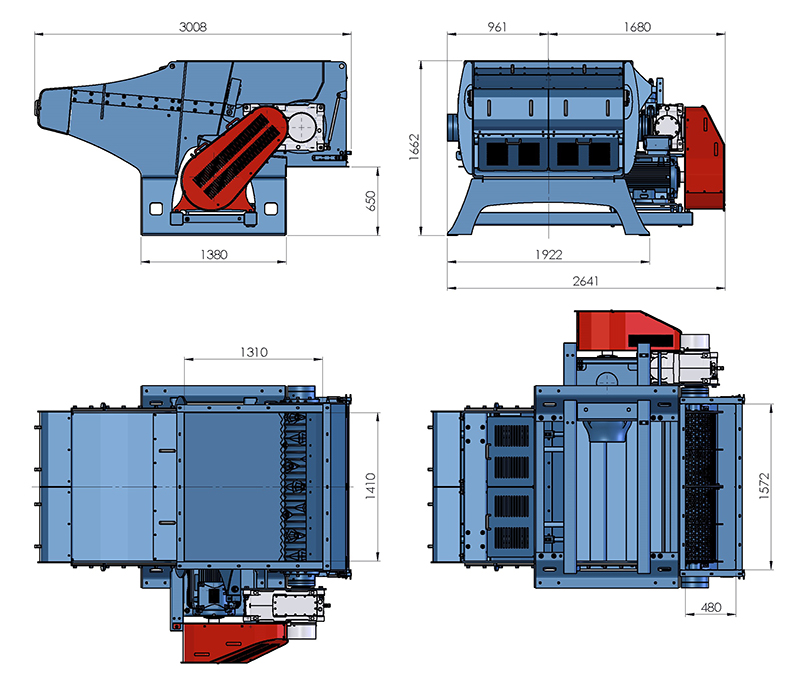

Technical drawing & table

-

Type

-

RU 14-4

-

Rotor ø mm

-

375

-

Infeed opening [mm]

-

1310 x 1410

-

Dimensions of tools [mm]

-

60 x 60

40 x 40

|

Type |

Rotor ø mm |

Infeed opening [mm] |

Dimensions of tools [mm] |

|---|---|---|---|

|

RU 14-4 |

375 |

1310 x 1410 |

60 x 60 |

-

Number of tools [pcs]

-

21 / 32 / 42

32 / 48 / 64 -

Screening surface [m²]

-

0,9

-

Motor [kW]

-

37 - 55

-

Weight [kg]

-

5570

|

Number of tools [pcs] |

Screening surface [m²] |

Motor [kW] |

Weight [kg] |

|---|---|---|---|

|

21 / 32 / 42 |

0,9 |

37 - 55 |

5570 |

Bruks-Siwertell

Bruks-Siwertell