Idler belt conveyors

Back to Conveying

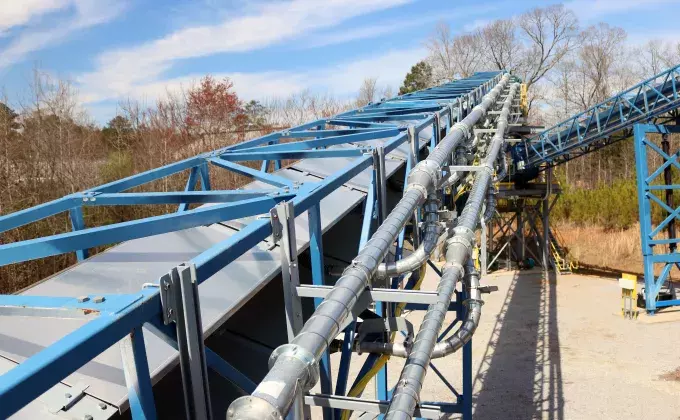

Belt conveyors deliver decades of proven, reliable performance

Our idler belt conveyors employ the most well-known, robust technologies for conveying huge volumes of dry bulk material reliably and cost-effectively rocesses and storage. As long as material can form a pile, it can be carried on a conveyor of this type.

In addition to their material carrying flexibility, idler belt conveyors offer low energy consumption and their robust construction delivers a long service life, which often combine to make them the ideal choice for many large-scale dry bulk handling facilities.

The operational performance of Bruks’ idler belt conveyors are proven with thousands of installations worldwide, from single-line conveyors to complex conveying systems.

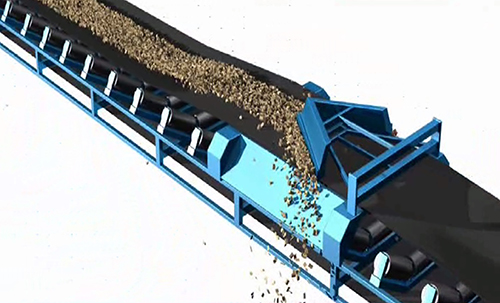

Simple, effective, clean technology

Bruks Siwertell belt conveyors essentially rely on a heavy-duty rubber-coated nylon core belt, which is pulled from the head end, and formed into a curved trough shape by ‘idlers’. These are cylindrical rollers that support the bottom and sides of the belt as it moves.

Belt-type conveyors can easily be equipped with additional features to tailor them for an operation. These include optional trippers or belt ploughs for distributing and stacking materials. They can also have ridged, otherwise known as cleated, belts for high conveyor inclination and be fitted with covers for dust and moisture control. Optional covers and spillage plates ensure clean, spillage free belt conveying with minimal dust creation.

Modular design offers fast, efficient maintenance

Our idler belt conveyors were developed with a modular design using standardized components. This ensures the rapid availability and delivery of spare parts and makes maintenance easy. It also adds to their cost-effective operating profile, by reducing their through-life service costs.

When not used as stand-along installations, they are ideal in combination with ship unloading/loading equipment and in marine terminal applications, matching the up and down-stream conveying requirements of ship loaders and unloaders. The belt conveyor program meets the requiremetens of large scale operators in terms of high capacity conveying, dust and spillage free from ship to storage, meeting the most stringent environmental regulations. The program is based on modularized design concept minimizing design and delivery time. Tailor made jetty belt conveyors to match the Siwertell ship unloaders and ship loaders are part of this program. These conveyor system, when combined with the Siwertell Movable Transfer trolley or Siwertell Belt Tripper, offer a seamless transfer that is totally dust and spillage free.

The belt conveying systems are highly suitable when very high capacities are needed, typically handling materials such as coal, ores, minerals, grain, feedstuff and fertilizers.

Bruks-Siwertell

Bruks-Siwertell