Aeroslide

Back to Conveying

Aeroslide conveyors are used to handle easily-fluidized materials

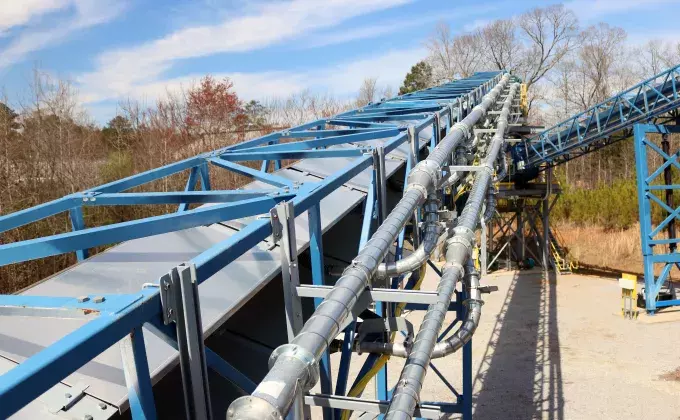

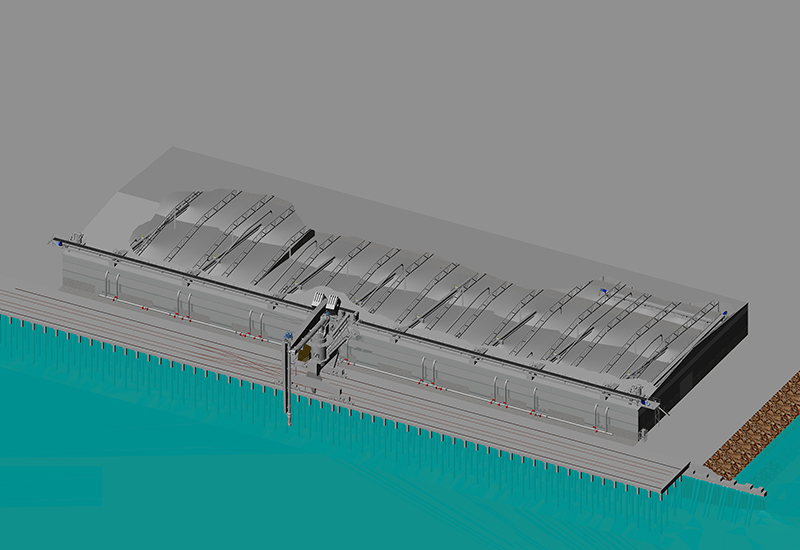

Aeroslide conveyors are supplied for various applications in bulk terminals, and they must be installed on a downward slope, as gravity is essential to their operation. They can be ideal when height restrictions are a major factor.

Siwertell aeroslides are used to convey dry, powdery bulk commodities such as cement, dry fly ash and alumina. They offer continuous, clean transportation with no limit to the conveying length and take advantage of gravity to transport large amounts of material over long distances at relatively slow speeds.

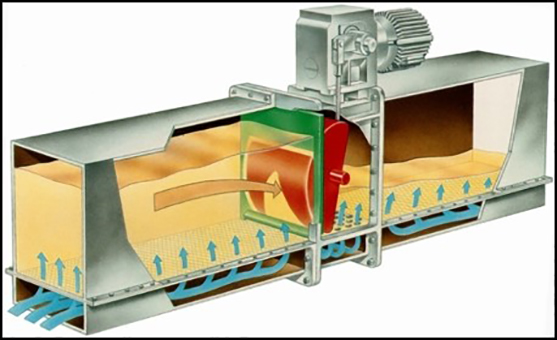

Siwertell aeroslides are constructed in two sections separated by an air-permeable membrane. The dry bulk material occupies the upper section, while the fluidising air supply is introduced via the lower section. Installed with a slight downward inclination, the aerated material flows like a liquid under the effect of gravity.

Economical, clean and kind to cargo

Siwertell aeroslides offer a number of advantages for the operator including low investment costs and low energy consumption. With few moving parts, reliability is high and maintenance requirements and costs are low. Aeroslides provide great flexibility, and their totally-enclosed construction ensures extremely clean conveying operations. They also handle their cargo carefully, with little or no degradation.

Combines well with other conveying systems

The aeroslide’s requirement for a downward flow of material often fits well with a terminal’s topography. In cases where a continual downward flow is not possible, an aeroslide system can easily be combined with one of Bruks Siwertell’s other conveying technologies to provide an effective integrated solution.

Bruks-Siwertell

Bruks-Siwertell