Siwertell screw conveyors are designed to handle a great variety of dry bulk materials, such as cement, lime raw meal, apatite, urea, fly ash and gypsum, under hard conditions. For long distance and high lifting heights, two or more screw conveyors are arranged in series. When large capacities are to be handled, the conveyors can run parallel to each other. The screw conveyors are completely enclosed, which reduces dust creation to a minimum.

They have been supplied to numerous customers for installations worldwide in e.g. industries, port terminals, ships, silos, and power plants. The heart of Siwertell screw conveyors is the easily replaceable intermediate bearing, specially developed to resist wear.

Siwertell horizontal and vertical screw conveyors operate with the helical flight pushing and throwing the bulk material forward by rotational action. Capacities range from 30 to 1,700 m³/h. The rigid and heavy-duty construction of these conveyors reduces wear and enables easy maintenance at infrequent intervals. They are suitable for applications in any kind of environment indoors and outdoors as well as on ships. Modular construction ensures swift and easy installation in new and existing bulk conveying systems.

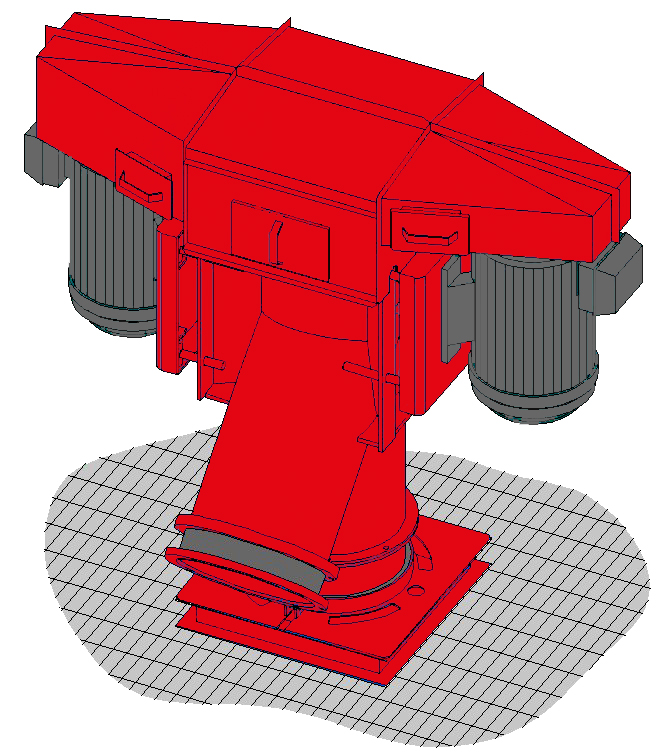

Vertical screw conveyor 300-700 Singel motor drive

vertical screw conveyor 300-700 twin motor drive

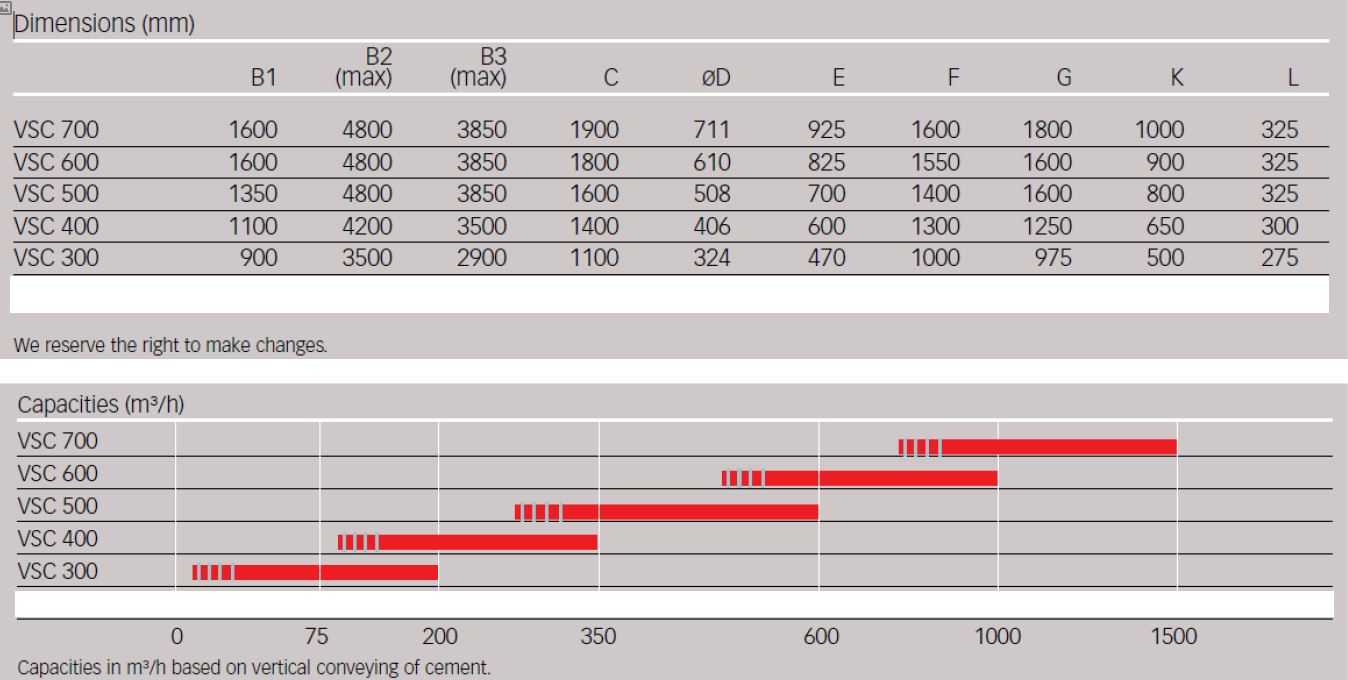

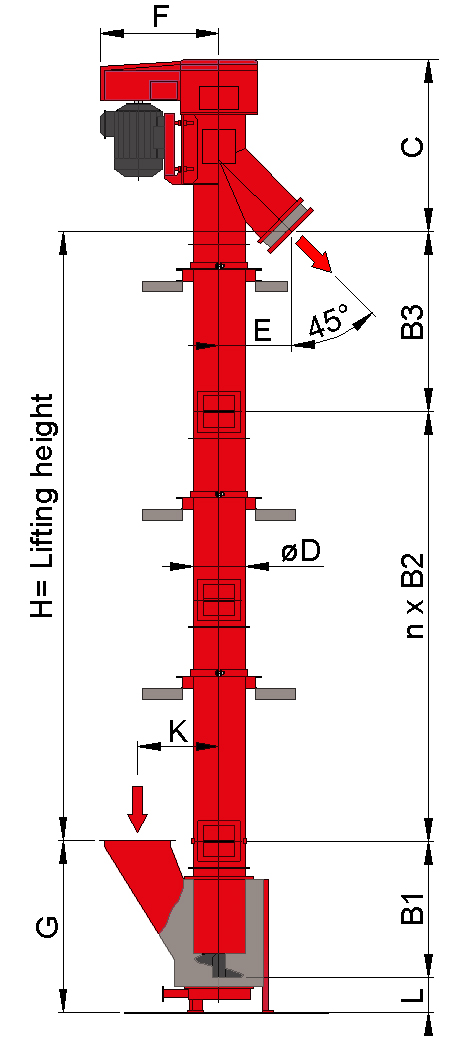

Dimensions vertical screw conveyor

Vertical screw conveyor features

- long-life intermediate bearings

- loading box with fluidised bottom

- conveying with different angles

- single or twin motor drive

- v-belt transmission

- speed guard included

- flexible connection at outlet

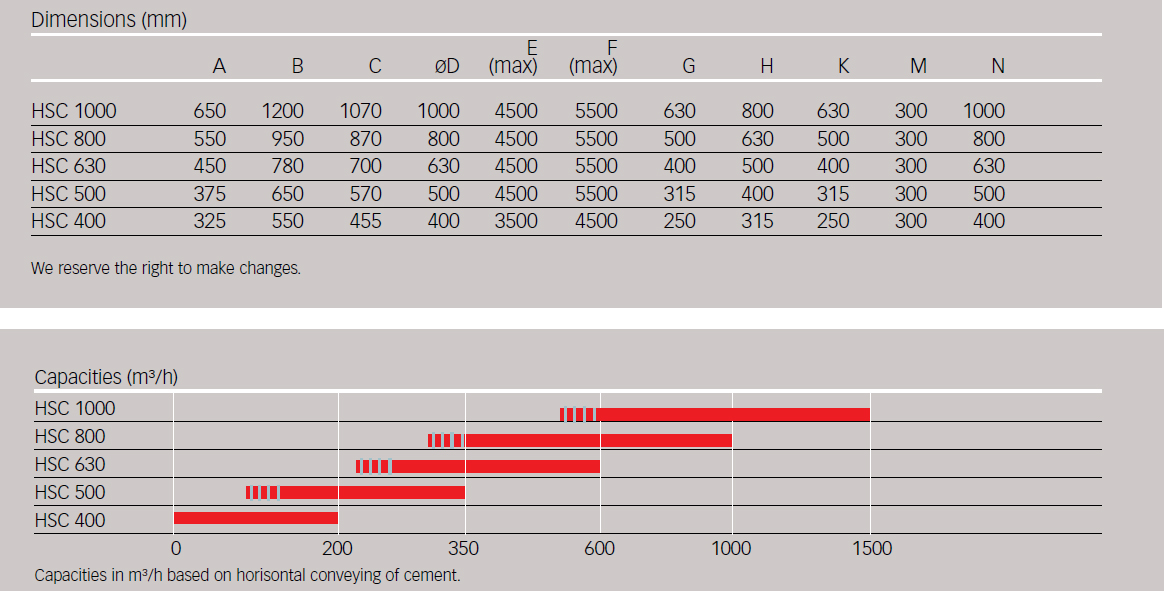

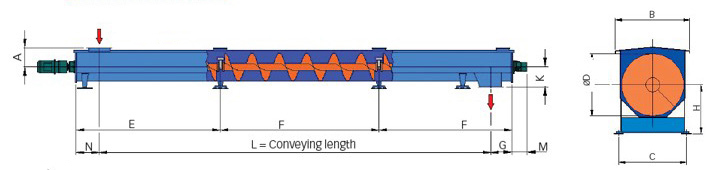

Horizontal screw conveyors

Horizontal screw conveyors Features

- reversible conveying direction

- one or more inlets

- one or more outlets

- drive unit can be located at loading or unloading end

- inclined conveying

- various types of drive units

- speed guard included

Bruks-Siwertell

Bruks-Siwertell