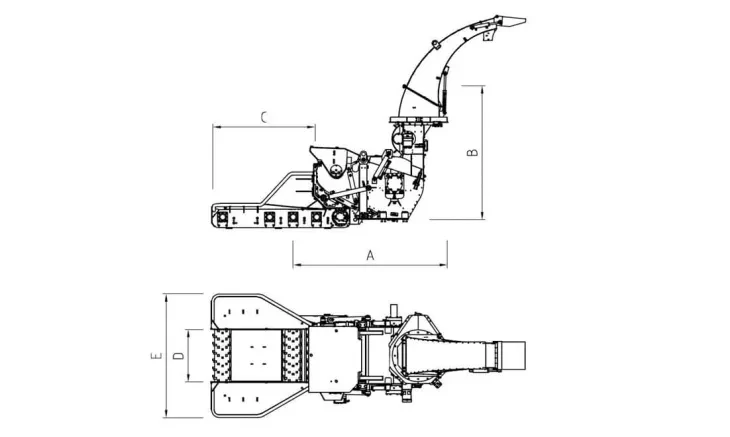

Chipping features of 806.2 Chipper

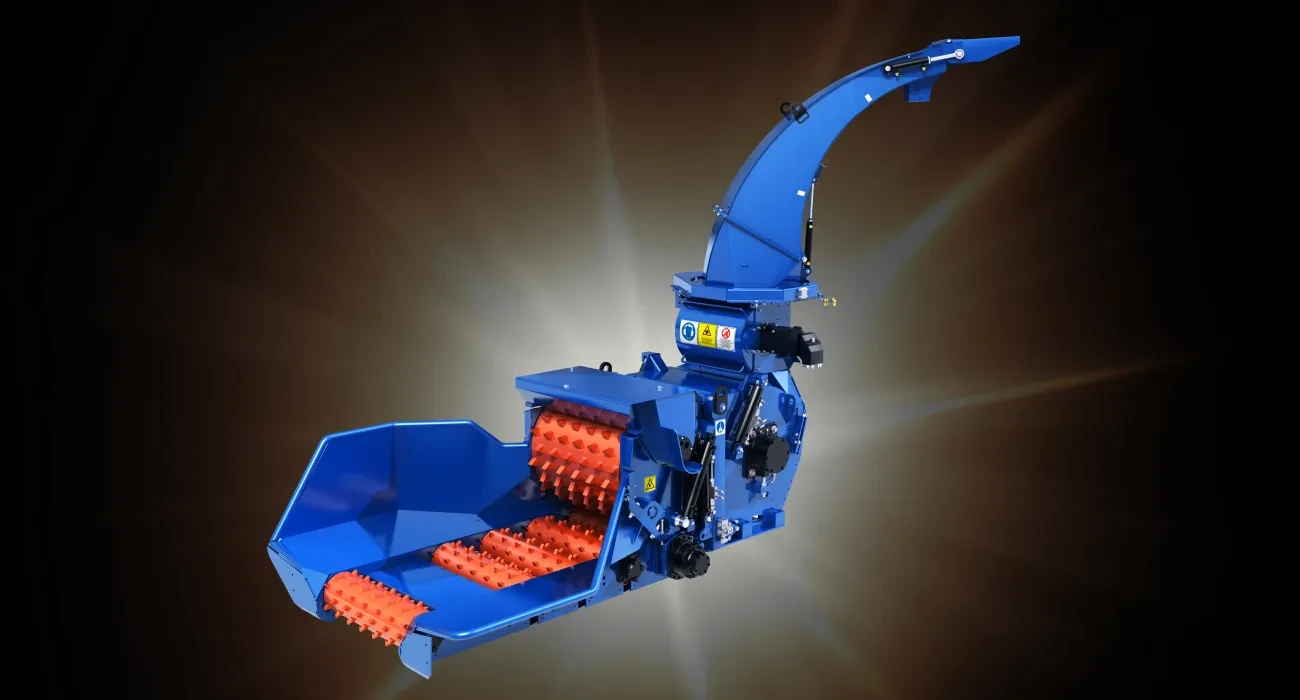

Our time-tested Bruks technology ensures that wood flows smoothly through the chipper, minimizing dust, wear and energy consumption, while maintaining extremely high wood chip quality. The Bruks 806.2 features a particularly powerful infeed, very efficient chipping drums and our latest Bruks chip accelerator, delivering improved chip discharge.

Chipper unit

The chipper has a robust housing with a hydraulically driven feed unit offering high retraction forces. A built-in hydraulic motor drives the powerful 800mm upper roller. During operation, the roller rests on top of the material, but can easily be hydraulically lifted and lowered to exert downward force if needed. All rollers have hardened teeth to ensure high durability.

When the material has been cut, the chips pass through a chip screen into the hydraulically powered chip accelerator and through the chip tube.

The chipper has been designed for easy, safe maintenance. The knives are readily accessible through the hydraulically operated hood and to ensure high durability, wear parts are exchangeable and made of Hardox steel.

Drum chipper

To ensure superior chip quality, as well as high infeed speeds and chip production, two full-length knives and a closed drum are specified as standard.

Several different drum versions are available to optimize the results, depending on the various types of wood chips required from the different raw materials. Chip length can be set and adjusted from 11 to 45mm.

Infeed table

The 806.2 has a long feed deck, equipped with three to five rollers, with an extremely low transport height. The outer rollers are chain driven by hydraulically powered inner rollers. The rollers have hardened teeth to ensure high durability and highly efficient infeeds.

The table’s design makes it very easy to feed in a variety of materials from logging residues to whole trees and logs. We also offer table-sides, high or low, for different applications, and there are standard or heavy-duty versions, which can be configured to fit your needs.

Chip output: the chip accelerator and chip tube

Our latest chip accelerator offers a very powerful output and adjustable speed, independent of the engine’s revolutions. This delivers an optimal and smooth chip discharge, and minimizes dust emissions as the chips are efficiently handled within the drum and chip tube. It has also been designed for minimal energy consumption.

We offer a number of size configurations for our chip tubes; high, low, long or short, which all facilitate optimal control of the chip output. They are all hydraulically controlled, and can be turned and folded, making transport easier for height restrictions.

The chip tubes are equipped with a hydraulically operated control deflector. In cases of very high productivity and wear and tear, the outer sweep of the tube can be exchanged, extending the service life of the overall tube.

Bruks-Siwertell

Bruks-Siwertell