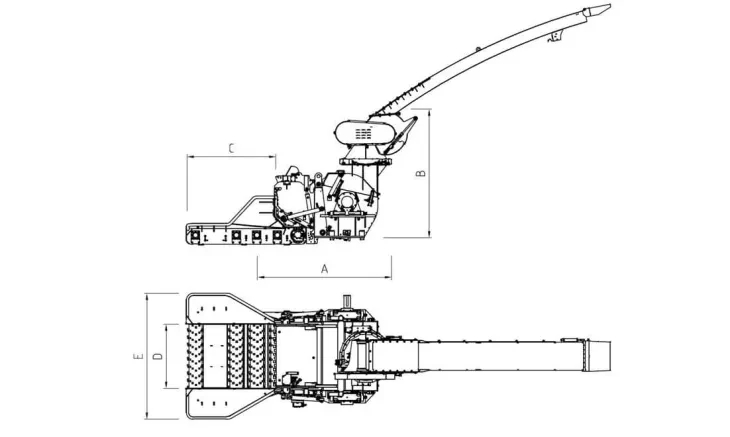

Drum chipper

The 1006 series of Bruks mobile chippers feature a heavy-duty drum chipper. These can be fitted either with their own self-contained 585kW (796hp) diesel engine, or powered by the truck’s 515 to 590kW (700 to 800hp) diesel engine via a gearbox, driveshaft, and belt transmission. Both assembly options ensure the high-torque properties needed for very high capacity chip production.

The 1006 chipper is designed for heavy-duty applications. The drum chipper has a welded, robust housing with any parts exposed to wear and tear made of Hardox steel. It has an enclosed chipping drum with the chips discharged via a chip accelerator and chip tube. A combination that provides the most energy-efficient chipping process and a consistently high chip quality.

Effective feeds

The hydraulically driven feed units have a large, powerful upper feed roller, which can be raised and lowered. A long infeed table is equipped with hydraulically powered rollers. These have Hardox steel teeth designed with an aggressive form to ensure an efficient infeed. The feed openings for the chipper drum have a height of 720mm with a width of 1.2m.

The table’s width, length and high sides makes it very easy to feed in a variety of materials from logging residues, whole trees and logs. The table is also equipped with an extra turning point on the lower feed unit, providing a lower height, raised infeed table during transport.

Drum and transport

The chipper drum has four entire knife-mounting positions, making it possible to easily shift between chipping with four knives for the production of fuel chips or with eight knives for the production of micro-chips.

Chipper drum has a diameter of 1.0m and a speed of about 750rpm at maximum engine speed, giving a high torque during chipping operations. The chipper drum has a full metal jacket design with replaceable wear parts. The anvil, with shear bolts, is positioned to minimize damage in case scrap material enters the chipper.

Chip transport takes place through a screen into an integrated hydraulically powered chip accelerator, which does not use additional air, reducing spillage and dust emissions. From the accelerator, wood chips are funnelled out through the chip tube for optimal, precise ejection of the chips.

The entire chipper is built for easy, safe maintenance. The knives are readily accessible through the hydraulically foldable hood and Hardox steel wear parts are easily replaceable.

Bruks-Siwertell

Bruks-Siwertell