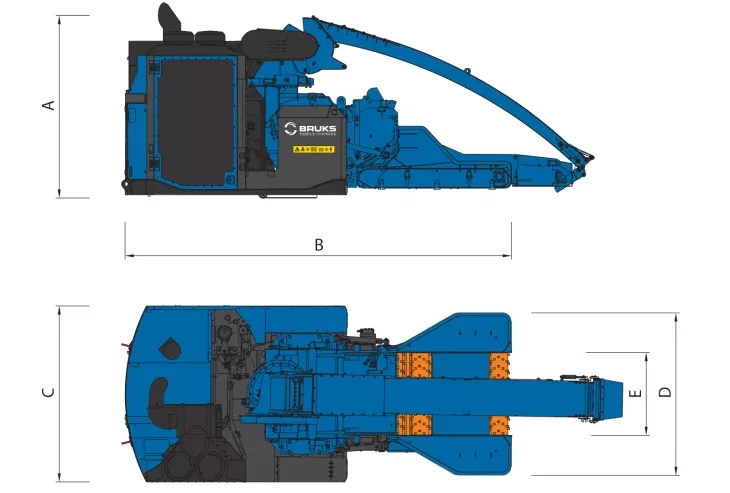

Base machine

The chipping unit consists of a 1006 drum chipper, complete with its own diesel engine and electrical and hydraulic systems, with everything built on a robust mounting frame. It is principally dimensioned for processing energy wood, brushwood and parts of trees, and should be installed on a truck with corresponding payload capacity and dimensions.

Drum chipper

The 1006 industrial wood chipper is designed for heavy-duty conditions. It has a powerful infeed and closed drum for best chip quality, with chip output via a chip accelerator and chip tube. This combination provides the most energy-efficient chipping process and a consistently high chip quality.

Mounting frame

The chipper unit stands on a mounting frame with integrated brackets for the chipper and engine installation. The frame is equipped with a slewing ring that provides a rotatable unit, which can be operated from either side. A roofed cage with hatches and doors protects the diesel engine, hydraulic and electrical systems.

Diesel-engine Volvo TWD 1683VE

The latest 1006 units are fitted with Volvo’s state-of-the-art TWD 1683VE diesel engines, which meet the European Union (EU) Stage V regulations. The engine offers a power output of 585kW (796hp) and a torque rated at a maximum of 3,650Nm, delivering more power and torque in the speed range used during chipping. Especially favorable for chipping is the high, straight torque curve down to lower engine speeds where, at 1,000 rpm, the torque is at just over 3,500Nm. These precise power and torque curves are also extremely helpful when it comes to attaining the lowest possible fuel consumption during chipping.

The complete installation includes a side-by-side mounted radiator with power demand-controlled reversible fans, starter batteries, air intake with centrifugal cleaner, exhaust system and a 400-liter fuel tank with the possibility of fitting an additional tank on the truck. Power transmission is via belt transmission.

Hydraulic system

1006.3 RT industrial mobile wood chippers feature an advanced hydraulic system. Their 120-liter stainless-steel hydraulic oil tanks have a patented CycloneConcept insert. This vents the return oil and allows the necessary volumes of hydraulic oil to be vastly reduced, along with the size of the stainless-steel tank. The overall result minimizes environmental impact and operating costs.

The hydraulic system is a load-sensing type and is powered using a variable pump. Proportional valves enable the exact operation and control of the infeed. A hydrostatic pump enables the chip accelerator to run at a constant speed regardless of engine’s revolutions. As an option, the machine can be equipped with a hydraulic pump for a crane.

The hydraulic cooler is located above the engine cooling system. A 24V electric-drive hydraulic pump is used as a service pump to operate the hydraulic functions when the engine is switched off, for example, when changing the knives during maintenance.

Electrical and control system (IMC)

Our advanced control system is built on a well-proven platform of hardware and our own in-house software, intelligent mobile chipping (IMC). Together, these provide a complete electrical control and monitoring system for the chipper unit. An optional crane control can also be integrated in the IMC system.

The chipper and engine functions are operated from the cabin where the operator can monitor all the engine’s parameters as well as the hydraulic system. Monitoring equipment and automatic controls for chipper safety functions, such as the anvil holder’s position and electronic infeed load control, are also included.

Chipper controls are mounted beside the crane levers and the large touchscreen is positioned at an ideal viewing angle for the operator. The color screen can be connected to external cameras. It is designed to be an intuitive communication link between the operator and monitoring and setting the chipper functions.

The chipper also features a remote connection via a global system for mobile communications (GSM) to deliver easy online troubleshooting via Bruks Siwertell’s support center.

Bruks-Siwertell

Bruks-Siwertell