Outstanding performance with consistently high through-ship capacity

Our Siwertell screw-type ship unloaders and ship unloading solutions are designed to transfer dry bulk cargo from ship to shore in the most efficient, environment-friendly way possible. They deliver high rated capacities, excellent through-ship performance, low environmental impact and decades of reliable service, offering dry bulk operators the potential to maximize the sustainability and profitability of their terminals.

The same ship unloader can handle almost any dry bulk material without requiring changes to the equipment. Hundreds of Siwertell screw-type ship unloaders have been installed worldwide since their introduction to the market in 1974. Time and again they have proven to out-perform every other dry bulk handling ship unloading option available on the market.

HALF A CENTURY OF CHANGE: SIWERTELL TECHNOLOGY IS STILL SETTING THE PACE

Siwertell technology and brand is celebrating its fiftieth anniversary this year, and since 2018 it has been part of Bruks Siwertell Group. Over the course of the past five decades, Siwertell technology has revolutionized the dry bulk handling industry, eliminating material spillage, minimizing dust emissions, and continuously setting market-leading capacities.

UNIQUE SHIP UNLOADING TECHNOLOGY

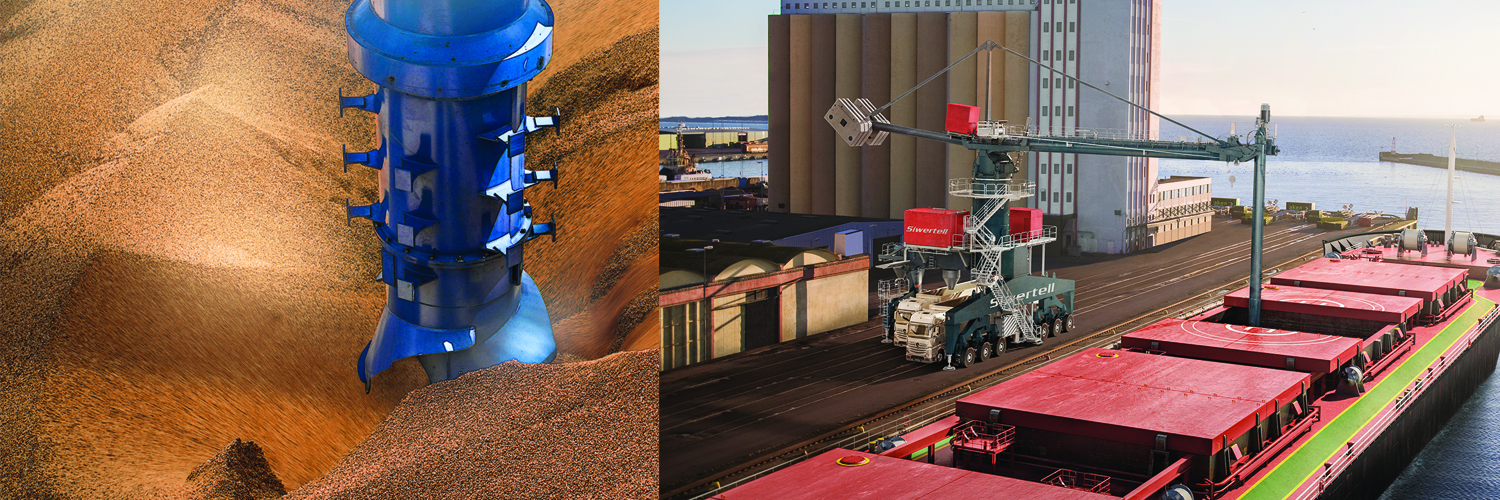

The success of Siwertell screw conveyor technology is based on its unique inlet feeder. The counter-rotating inlet gathers material from the hold and feeds it into the screw mechanism inside. The added rotation of the outer casing stops lumps of cargo collecting inside the mechanism. The vertical conveying arm can operate at a perpendicular angle to the cargo, or move through +/-30 degrees, allowing it to efficiently unload the whole cargo shipment while saving space on the quay.

Submerging the screw head and its counter-rotating casing beneath the surface of the cargo creates a totally enclosed system from one end of the vertical conveying arm to the other, preventing cargo from being thrown out of the screw mechanism. Furthermore, no dust clouds are created from cargo avalanches or repeated contact with the cargo in the hold.

This enclosed conveyor system and dust filters fitted as standard minimize dust emissions and eliminate spillage. They also avoid any unnecessary cargo waste and jetty clean-up costs. Siwertell ship unloaders offer a sustainable solution to dry bulk handling operators.

NEXT-GENERATION SERVICE AGREEMENTS

Our commitment to customer service means that we stand by our deliveries throughout their lifetimes. By selecting the support elements that you require, our planned service agreements are tailored to meet your needs. They are applicable for dry bulk handling equipment including ship unloaders, loaders, conveying systems and terminal operations.

EXCELLENT SHIP UNLOADING PERFORMANCE

Siwertell ship unloaders offer a wide range of rated capacities from 200t/h to very high rates of more than 3,000t/h. However, the true measure of their excellent performance is their through-ship capacity; the time it actually takes to completely discharge a dry bulk carrier.

In addition, outstanding performance should be linked not only to ship unloading rates and efficiency in the unloading process, but also to the ability to unload sensitive cargoes without degradation of the cargo and with minimal power consumption. Siwertell unloaders can be ordered as standalone products or as part of complete bulk handling solutions.

OPTIONAL FEATURES ENHANCE SHIP UNLOADING EXCELLENCE

Siwertell ship unloaders are equipped with our unique inlet feeder that ensures efficient material pick-up into the vertical screw conveyor, providing consistently high ship unloading capacities.

Different designs of feeder are used to optimize unloading performance depending on the material being handled, and salt is a particularly good example.

Salt handling Siwertell ship unloaders are fitted with an optimized inlet feeder able to withstand not only the corrosive properties of salt, but also the significant digging forces needed to discharge it from the hold at high capacities. Furthermore, their walkways, handrails and electrical compartments are manufactured from stainless steel, which does not rust easily.

Conveyors are available in different sizes depending on cargo material and the capacity required. Siwertell ship unloaders can be fitted with outlets to enable the direct discharge to trucks and rail wagons or for discharge onto any type of jetty conveyor.

SAFE SHIP UNLOADING, WHATEVER THE CARGO

Even in situations where cargoes have proven to be challenging for other ship unloading systems, Siwertell continuous screw-conveyor technology has proved itself many times over. For example, sulfur is well-known for its combustion risk in enclosed spaces, which has prolonged the use of non-enclosed grab or bucket-chain ship unloading systems to handle this highly volatile dry bulk material.

To overcome this issue Bruks Siwertell developed the Siwertell Sulfur Safety System (4S) for its ship unloaders, ensuring the early detection and containment of fires and explosion-proofing. The 4S also provides a safe method for handling the rising demand for oxygen-depleting cargoes such as biomass, and also grain.

QUIET PLEASE, SHIP UNLOADING OPERATIONS IN PROGRESS

Our ship unloading systems not only address dust emissions, spillage, and energy consumption, they also consider the effects of noise pollution on port personnel and the surrounding environment. Although not silent, independently-verified tests have shown that Siwertell ship unloaders offer relatively quiet ship unloading operations.

A SMARTER INVESTMENT: CHOOSE LONG-TERM VALUE

Siwertell ship unloaders offer important cost savings to ship unloading operations through:

- Low energy consumption

- Easy operation

- Minimal material spillage

- High through-ship capacities that minimize shipping costs and maximize jetty utilization rates

- Low weight design

Tailored to meet your needs

The huge variety in port needs and terminal dimensions means that the majority of large-scale Siwertell ship unloaders and ship unloading systems are tailormade with each customer’s specific operation in mind.

Customers are able to work closely with Bruks Siwertell to specify every element of their ship unloader to ensure that it exactly meets their needs and at the same time maximize the operational efficiency and performance of their port terminal.

STANDARDIZED SHIP UNLOADING SOLUTIONS

For some operators, standardized ship unloading systems are the ideal solution. They deliver many of the advantages that tailormade ship unloaders offer, but have added cost benefits as they use standardized components. This also means that delivery times are usually much faster. If you need advice about which type of ship unloading system would best suit your needs, we are happy to help.

Examples of standardized systems include our popular road-mobile and port-mobile systems.

Complete bulk terminal solutions

Bruks Siwertell designs solutions for complete bulk terminals. We will work closely with you to make sure our solutions fit with your specific needs. Our high-capacity, high-efficiency unloaders, loaders, conveying systems and stacking and reclaiming systems stand to provide you with substantial cost savings from reduced operating times.

Bruks-Siwertell

Bruks-Siwertell