Port-mobile unloaders

Back to Ship unloading

Port-mobile unloaders: Optimized to deliver outstanding material handling

Our product development is driven by adding value and sustainability to dry bulk handling operations. This is exactly what our Siwertell port-mobile unloader can do. They offer full port mobility, excellent efficiency and rated capacities and reduced investment costs.

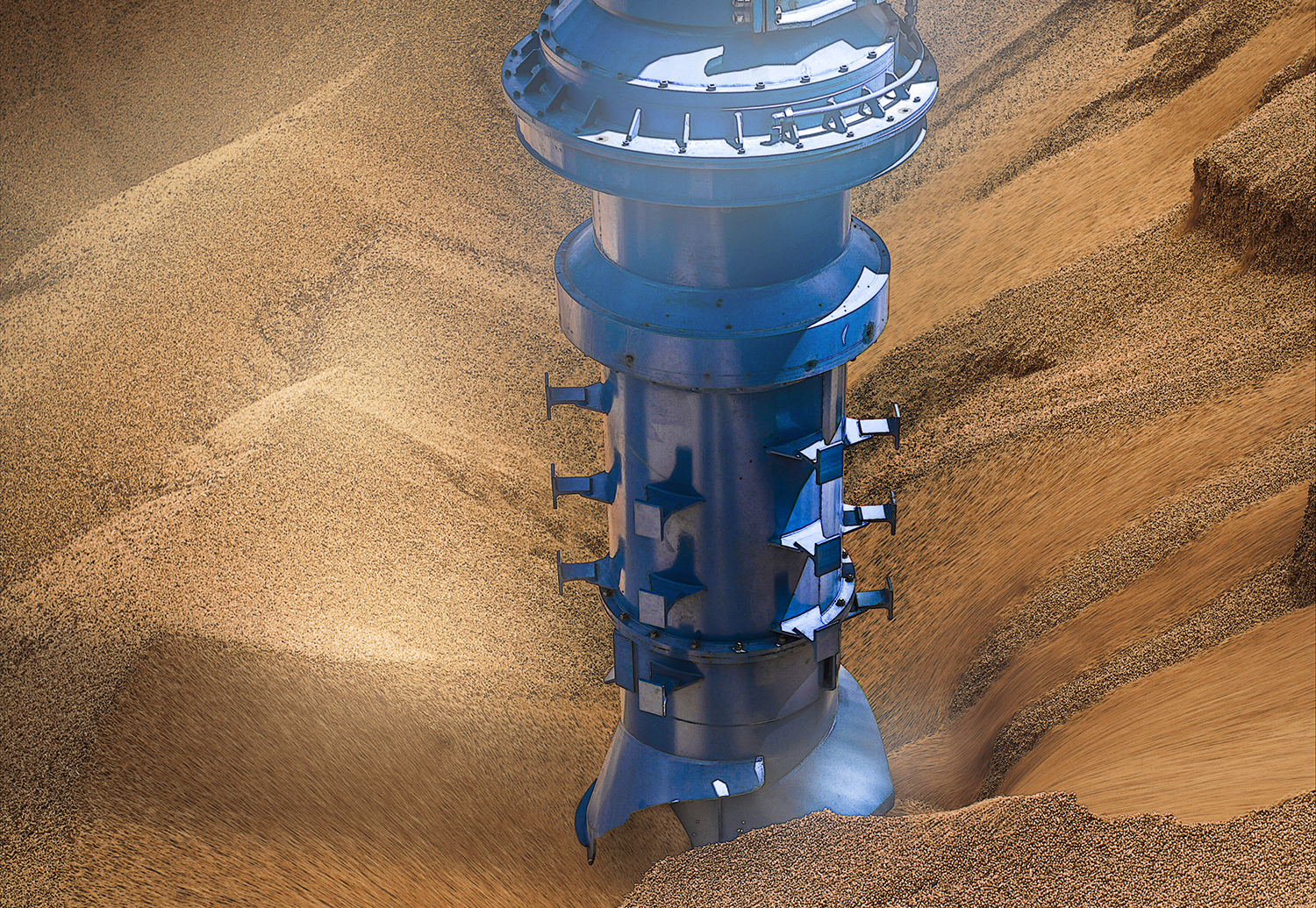

Able to handle materials such as grain, soybean meal, alumina and cement, the port-mobile unloader has been optimized on many key levels from its stable, low weight steel structure through to its gentle cargo handling, smooth cargo discharge, and cost-efficient operation.

Based on a standardized design to keep investment, maintenance and wear parts costs as low as possible, the port-mobile unloader is available as a (grain) 400t/h or a 600t/h unit; the Siwertell 400 PMU and the Siwertell 600 PMU. They are an ideal solution for operators looking for a port-based system and are able to discharge vessels up to 60,000 dwt.

SIWERTELL TECHNOLOGY ORDERED FOR ENCLOSED CEMENT HANDLING IN ADELAIDE

“The ship unloader will be fitted with a rubber-tire wheelbase ensuring in-port mobility,” he explains. “Furthermore, the jetty conveyor system will be installed in a recess so that the jetty remains clear for other activities. The entire system, from material pick-up in the vessel’s hold to the dome silo, will be totally enclosed, providing a virtually dust-free operation in the port, with no spillage.”

The new Siwertell ship unloader will be suitable for discharging bulkers up to 40,000 dwt at a rated cement handling capacity of 500t/h. It is planned for delivery in August 2023 and will be assembled on site. Read press release here.

Low material degradation

One of the greatest advantages when unloading delicate agri-bulk and sensitive powdery cargoes, such as alumina, with Siwertell screw-conveyor technology is low material degradation rates. These are delivered through an efficient, continuous conveying velocity, which avoids collisions between material particles and the inner wall of the conveyor, and therefore reduces the production of powdery fines.

A delicate approach

Fines are problematic for many types of cargo, and particularly so for grain and alumina; posing some significant financial and safety concerns.

For grain, the presence of fines can mean that the whole shipment is downgraded. They can make it more difficult to aerate, which increases spoilage rates, and they also have to be removed before milling. Furthermore, the greater the number of fines produced, the greater the dust emissions, raising the risk of fire and explosion in storage silos and other confined areas.

READ MORE ABOUT GRAiN HANDLING

Whereas, for alumina, aluminum smelting is very energy intensive and the process is extremely sensitive to the amount of fines in the material. Their significant reduction has a huge impact on the smelting plants energy consumption.

READ MORE ABOUT ALUMINA HANDLING

Terminal operators and third-party specialists have measured the level of fines before and after a Siwertell unloading operation and have confirmed these low degradation rates.

Cost-effective cement operations

The dry bulk cement market is strongly linked to the construction industry and its changes in demand. As populations increase, so does the need for infrastructure.

Being able to respond flexibly and efficiently with a dry bulk unloading system that ensures the dust-free discharge of large vessels, up to 60,000 dwt, is now an essential at many cement import terminals.

Our port-mobile units offer high-capacity unloading, delivering a reliable, asset-light, space-efficient operation with minimal downtime; ideal attributes for any port.

READ MORE ABOUT CEMENT HANDLING

Smooth cargo flows

As standard, the port-mobile unloader features a dual truck-loading system, with the option for a third, which delivers continuous, uninterrupted discharge operations as long as there are trucks available.

As these systems are not interlinked, one, two or three loading positions can be used to load trucks independently and simultaneously, delivering the fastest possible discharge times.

Furthermore, to minimize the impact of truck changeovers and to allow enough time to position the truck correctly, the unloader is equipped with a large-volume intermediate surge hopper.

Through-ship efficiency

Operational costs depend on total unloading times and therefore it is important to maintain high average through-ship capacities to reduce any demurrage costs. Unlike a pneumatic unloader, for example, which can only operate its intake nozzle in a vertical direction in the hold opening, a Siwertell unit can reach practically all areas of the cargo hold, including underneath the hatch opening and corners. This is made possible with the +/- 30-degree movement in the unloader's vertical arm combined with a +/- 20-degree luffing motion in the horizontal arm; maneuverability which directly translates into unloading efficiency advances and leaves less material for the payloader to move at final clean-up.

This capability, combined with the overall efficiency of continuous screw-type conveying technology, means that the Siwertell port-mobile unloader offers a higher through-ship rate than a pneumatic unloader.

Winning combinations

One of the port-mobile unloader's stand-out capabilities is that when not in use, it can relocate and stow elsewhere, leaving port thoroughfares and key operational areas clear. It is equipped with a self-propelled rubber-tire gantry and an advanced steering system for full maneuverability between operations. To secure the gantry in all directions when parked, the end pairs of axles, both on the sea-facing and land-facing sides, are turned by 90 degrees

-

Function -

Features -

Mobility -

Port-mobile with rubber tyres -

Motions -

Wide, fast slewing, luffing and pendulum motions of the conveying arm -

Conveying type -

Screw-type with low conveying velocity -

Buffer hopper -

Intermediate storage enabling continuous unloading -

Independent truck loading system -

Intermediate storage enabling continuous unloading -

Transport technology -

Enclosed material conveying

-

Function -

Benefits -

Mobility -

Flexible operation and ability to use the jetty without rails -

Motions -

Excellent reach into the ship's entire hold delivers the highest average efficiency rates on the market -

Conveying type -

Low cargo degradation rates -

Buffer hopper -

High unloading efficiency -

Independent truck loading system -

High unloading efficiency -

Transport technology -

No dusting or spillage

| Function | Features | Benefits |

|---|---|---|

| Mobility | Port-mobile with rubber tyres | Flexible operation and ability to use the jetty without rails |

| Motions | Wide, fast slewing, luffing and pendulum motions of the conveying arm | Excellent reach into the ship's entire hold delivers the highest average efficiency rates on the market |

| Conveying type | Screw-type with low conveying velocity | Low cargo degradation rates |

| Buffer hopper | Intermediate storage enabling continuous unloading | High unloading efficiency |

| Independent truck loading system | Intermediate storage enabling continuous unloading | High unloading efficiency |

| Transport technology | Enclosed material conveying | No dusting or spillage |

Advantages that deliver a competitive edge

- Reduced installation and investment costs

- Excellent reach into the ship's entire hold, delivering the highest average efficiency rates on the market

- Significantly lower material degradation in comparison with pneumatic conveyors

- Rapid truck filling times, with independent truck-loading spouts

- Close to zero dust emission

- Easy to switch between all kinds of grain cargoes, as well as soyabean meal and feedstuffs, and powerdery cargoes such as cement and alumina

Technical specifications

-

Model -

Siwertell PMU 400-2 -

Rated capacity -

150-400t/h, subject to material handled -

Maximum ship size -

60,000 dwt -

Vertical conveyor -

490mm/20.25m -

Horizontal conveyor -

700mm/23.5m -

Number of out loading units -

Two -

Dust collectors -

Included -

Travelling speed -

0-8 m/min -

Operation control -

Wireless remote control -

Diesel generator -

650 KVA -

Voltage -

400V/50Hz -

Maximum corner load (operation) -

180 metric tons/seaside -

Maximum corner load (travelling) -

120 metric tons -

Total number of axles -

3+3 seaside/3 landside

-

Model -

Siwertell PMU 600-2/3 -

Rated capacity -

200-600t/h subject to material handled -

Maximum ship size -

60,000 dwt -

Vertical conveyor -

490mm/20.25m -

Horizontal conveyor -

700mm/23.5m -

Number of out loading units -

Two/Three -

Dust collectors -

Included -

Travelling speed -

0-8 m/min -

Operation control -

Wireless remote control -

Diesel generator -

730 KVA/800KVA -

Voltage -

400V/50Hz -

Maximum corner load (operation) -

180 metric tons/seaside -

Maximum corner load (travelling) -

120 metric tons -

Total number of axles -

3+3 seaside/3 landside

| Model | Siwertell PMU 400-2 | Siwertell PMU 600-2/3 |

|---|---|---|

| Rated capacity | 150-400t/h, subject to material handled | 200-600t/h subject to material handled |

| Maximum ship size | 60,000 dwt | 60,000 dwt |

| Vertical conveyor | 490mm/20.25m | 490mm/20.25m |

| Horizontal conveyor | 700mm/23.5m | 700mm/23.5m |

| Number of out loading units | Two | Two/Three |

| Dust collectors | Included | Included |

| Travelling speed | 0-8 m/min | 0-8 m/min |

| Operation control | Wireless remote control | Wireless remote control |

| Diesel generator | 650 KVA | 730 KVA/800KVA |

| Voltage | 400V/50Hz | 400V/50Hz |

| Maximum corner load (operation) | 180 metric tons/seaside | 180 metric tons/seaside |

| Maximum corner load (travelling) | 120 metric tons | 120 metric tons |

| Total number of axles | 3+3 seaside/3 landside | 3+3 seaside/3 landside |

options

-

Auxiliary hoist -

6.3 metric tons (incl. consoles, platforms, weather protection cover and electric installation) -

Voltage 60Hz -

*Three phase frequency converter transforming land-based power supply from 60Hz to 50Hz -

Oil & Grease -

Start-up package including mineral or food grade-based products for initial fill up -

O&M documentation -

Printed operations and maintenance manuals inserted in binders (electronic/digital documentations in English as standard) -

Hand tool set -

Comprehensive set of hand tools including cabinet for maintenance purposes -

Special tool set -

Tool set comprising of special tools for erection and maintenance -

CE (Machine Directive and ATEX) -

Machine Directive and/or ATEX compliance -

Non-English manuals and/or HMI system -

Operation and maintenance documentation and HMI language in English included - other languages available as option

| Auxiliary hoist | 6.3 metric tons (incl. consoles, platforms, weather protection cover and electric installation) |

|---|---|

| Voltage 60Hz | *Three phase frequency converter transforming land-based power supply from 60Hz to 50Hz |

| Oil & Grease | Start-up package including mineral or food grade-based products for initial fill up |

| O&M documentation | Printed operations and maintenance manuals inserted in binders (electronic/digital documentations in English as standard) |

| Hand tool set | Comprehensive set of hand tools including cabinet for maintenance purposes |

| Special tool set | Tool set comprising of special tools for erection and maintenance |

| CE (Machine Directive and ATEX) | Machine Directive and/or ATEX compliance |

| Non-English manuals and/or HMI system | Operation and maintenance documentation and HMI language in English included - other languages available as option |

* Standard power plug for land-based power is 400V/50Hz, used for emergency operation and for stand still power.

Share:

Bruks-Siwertell

Bruks-Siwertell