Stationary & rail-mounted unloaders

Back to Ship unloading

Ship unloaders that optimize every dry bulk port

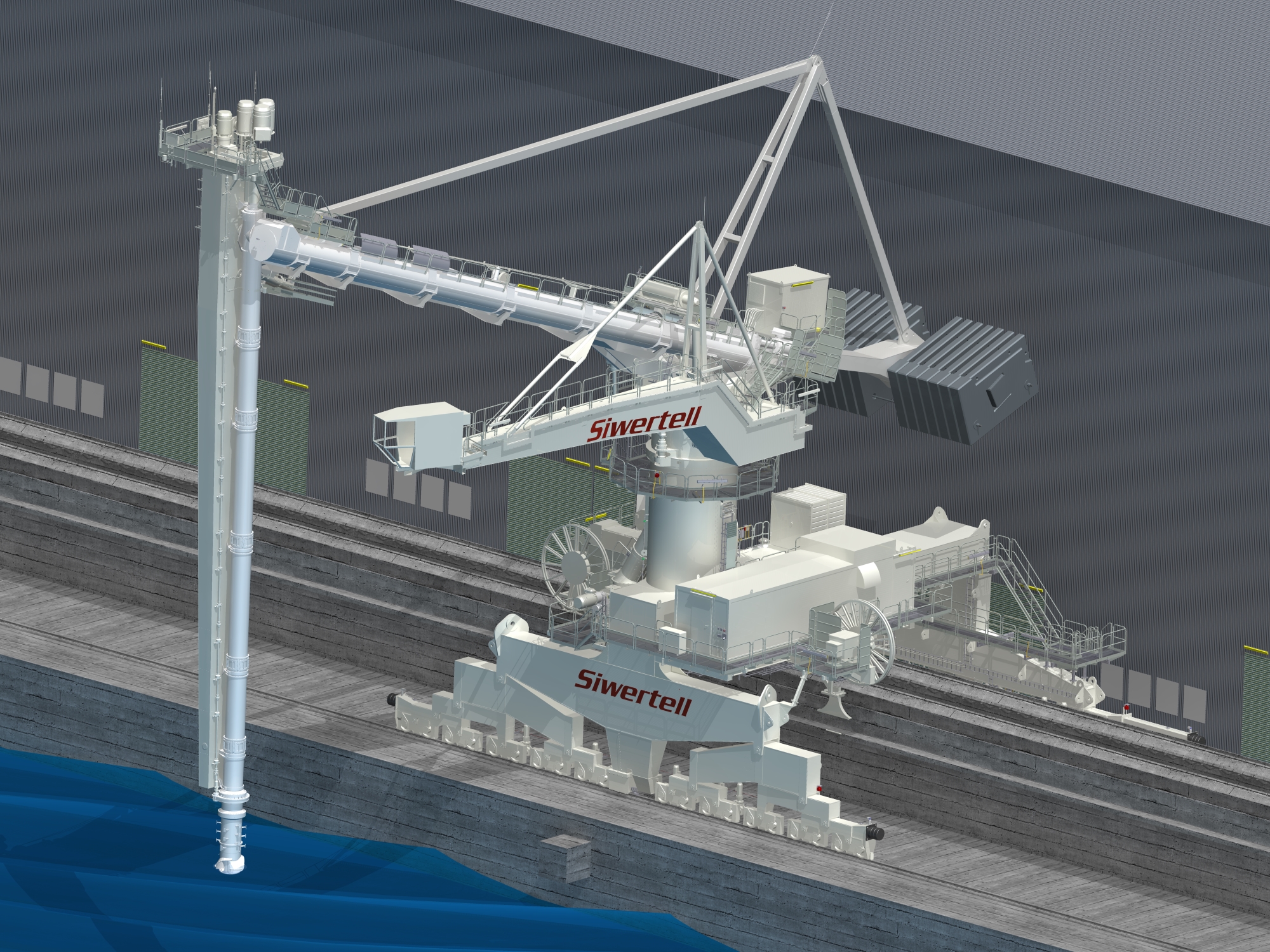

Bruks Siwertell designs unloaders that are able to optimize dry bulk material handling at every port, regardless of intake volume; from the smallest to the largest high-capacity operations. All our Siwertell ship unloaders are based on screw conveyor technology in combination with a unique inlet feeder. They reach right into the corners of a hold, resulting in quicker vessel turnarounds and reduced berth occupancy.

To achieve the most profitable unloading operation, it is essential that the ship unloader is well matched to the port’s intake requirements and the ships that it receives.

We can find the perfect match and offer the market’s highest through-ship efficiencies. Our large-scale ship unloaders have capacities up to 3,000t/h and can be installed as a fixed unit, or rail-mounted for traveling along the quayside. For smaller scale operations that require degrees of mobility, we offer road-mobile units and port-mobile units.

All industries appreciate the economies of scale, and this is equally true when it comes to bulk cargoes. Bigger ships transport their bulk cargoes more cost effectively across the oceans, but they can lose time in port because discharge rates are not optimised for large vessels.

Recognising the need for higher discharge capacities at the intakes for power stations, Bruks Siwertell has for some time been engaged in a development programme for a 3,000t/h screw type unloader. The work was completed a few years ago, and customers can now take advantage of the cost savings that can be delivered by the 50 percent increase in unloading capacity.

Cost savings through the right combinations

Cost savings can be achieved both in terms of initial investment and through-life operational costs, depending on the overall unloading performance required. Specifying two 3,000t/h unloaders instead of three 2,000t/h machines – to achieve a 6,000t/h capacity – results in an investment saving of up to 25 percent in favour of the 3,000t/h ship unloaders.

If the maximum possible capacity is required from the outset, then three 3,000t/h unloaders will provide an unloading capacity of 9,000t/h, as opposed to 6,000t/h from three 2,000t/h units.

Considering a Capesize vessel of 200,000 dwt and a through-the-ship capacity of 65 percent the unloading time using three 2,000t/h unloaders would be 51 hours. This would be reduced to 34 hours using three of the 3,000t/h unloaders.

Choosing unloaders according to ship size

The 3,000t/h unloader has been designed for a maximum vessel size of 230,000 dwt or a maximum beam of 50m. In general it is aimed at ships between 100,000 and 200,000 dwt. It can be used to discharge smaller vessels, but the efficiency level will not be as high as experienced with larger vessels.

Developing the high capacity unloader was technically demanding; involving far more than simply scaling up the existing product. The whole conveyor chain is new. Re-use of existing design has been minor. While it was possible to scale up most of the parts in the conveyor chain, the existing steel supporting structure design could not be adapted and we have developed a completely new solution.

3,000t/h can also be expressed as 50 tonnes per minute. But it is even more impressive when you realise that this is nearly a tonne of coal each second.

Click on the spots below to zoom in and learn more about the unloader features.

Contact us for more information

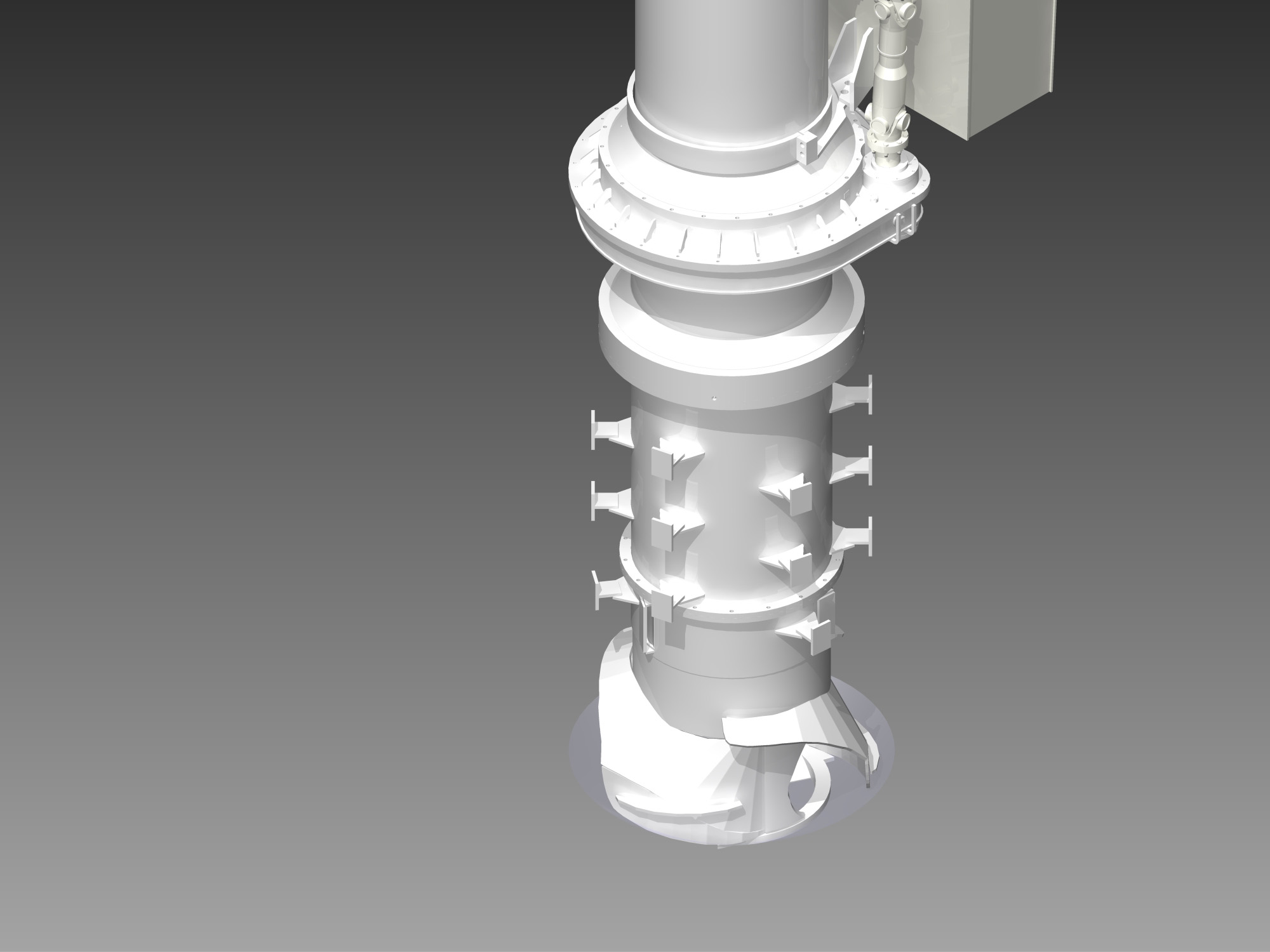

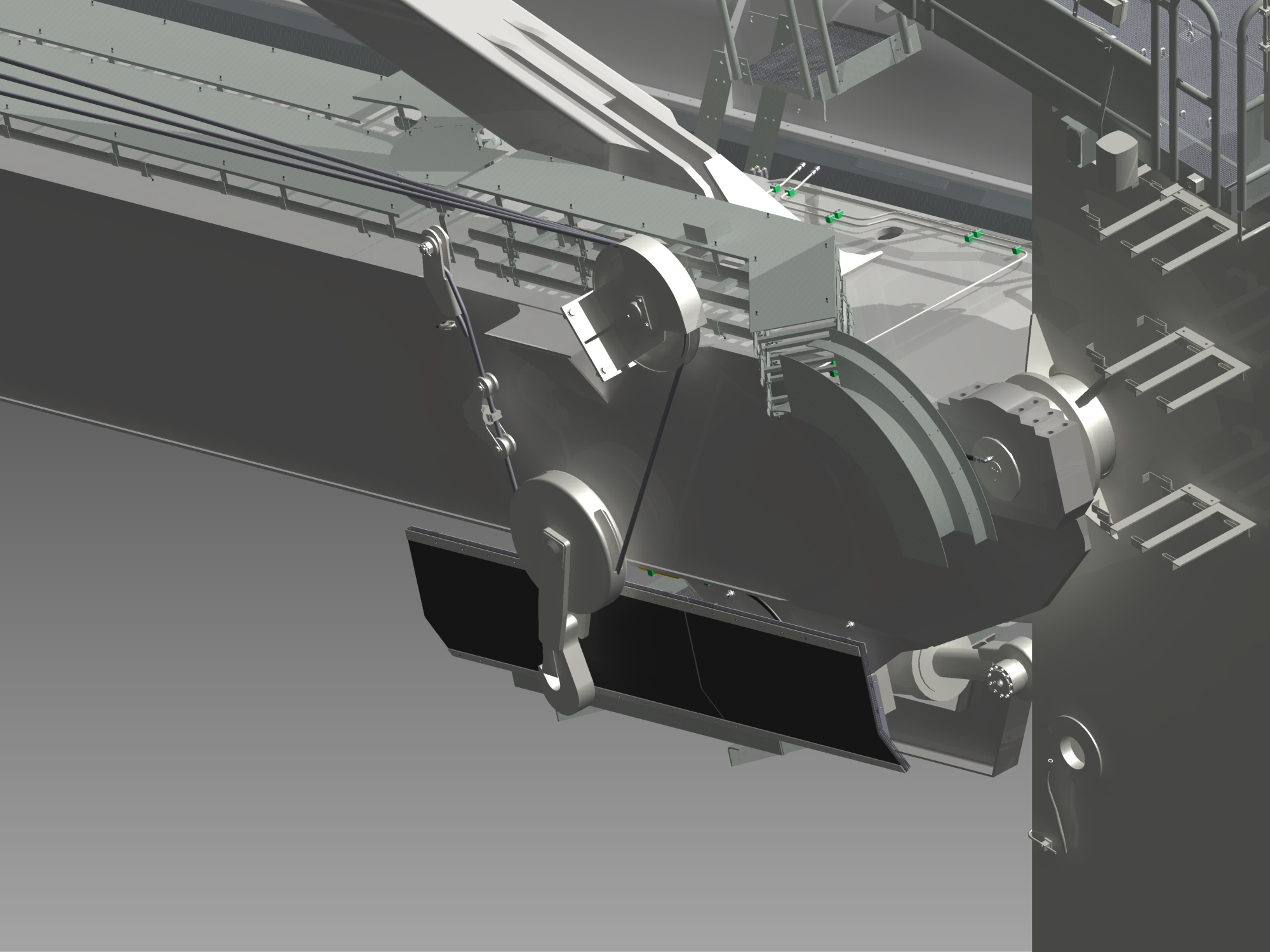

Inlet feeder

The counter-rotating inlet feeder was invented by Siwertell to increase the efficiency of cargo pick-up and the filling factor of the vertical conveyor. It gathers material from below the cargo surface in the ship’s hold to minimize dust creation and then feeds it into the vertical screw conveyor. Different designs of feeder may be used to optimize the unloading performance depending on the material being handled.

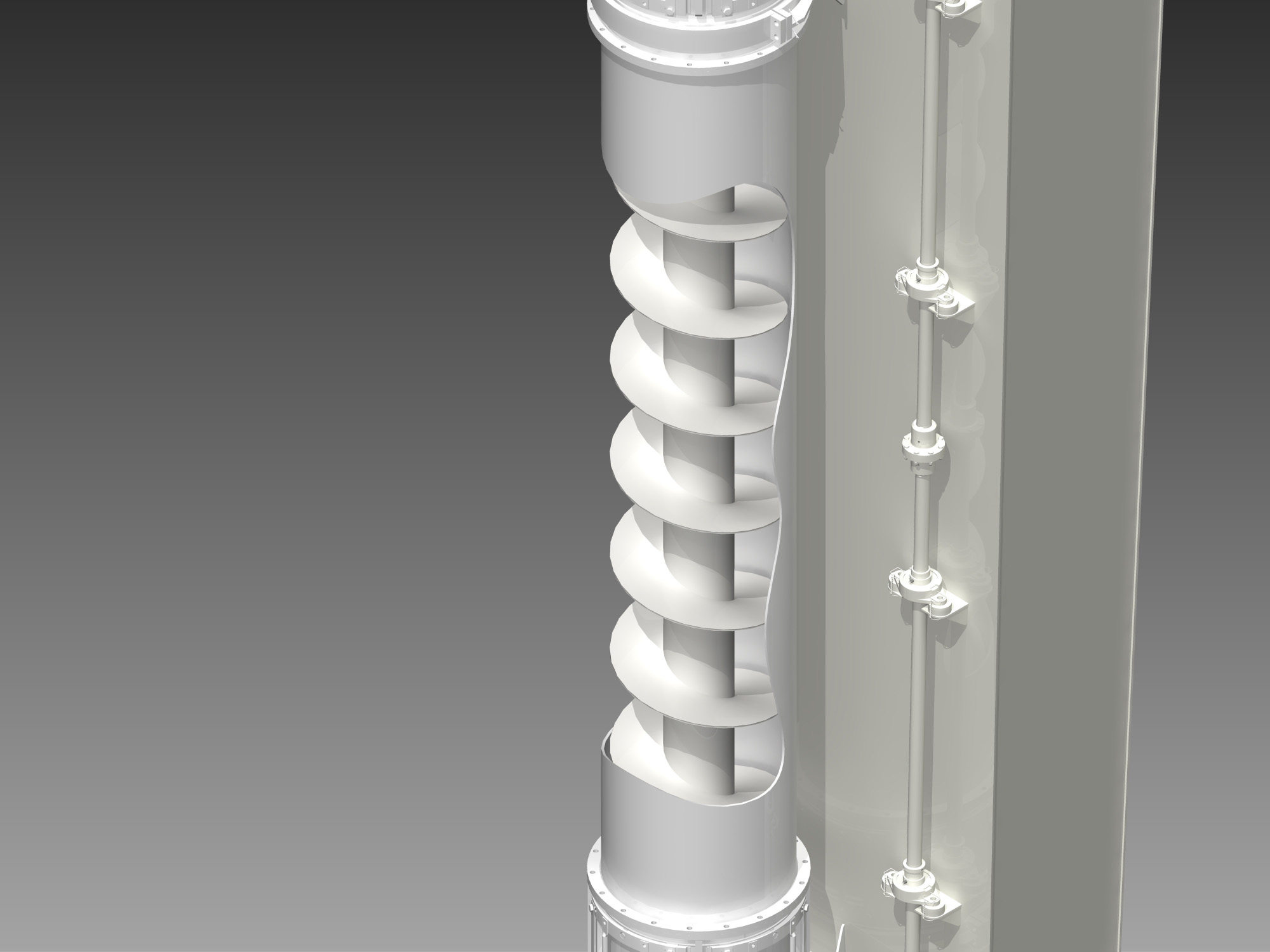

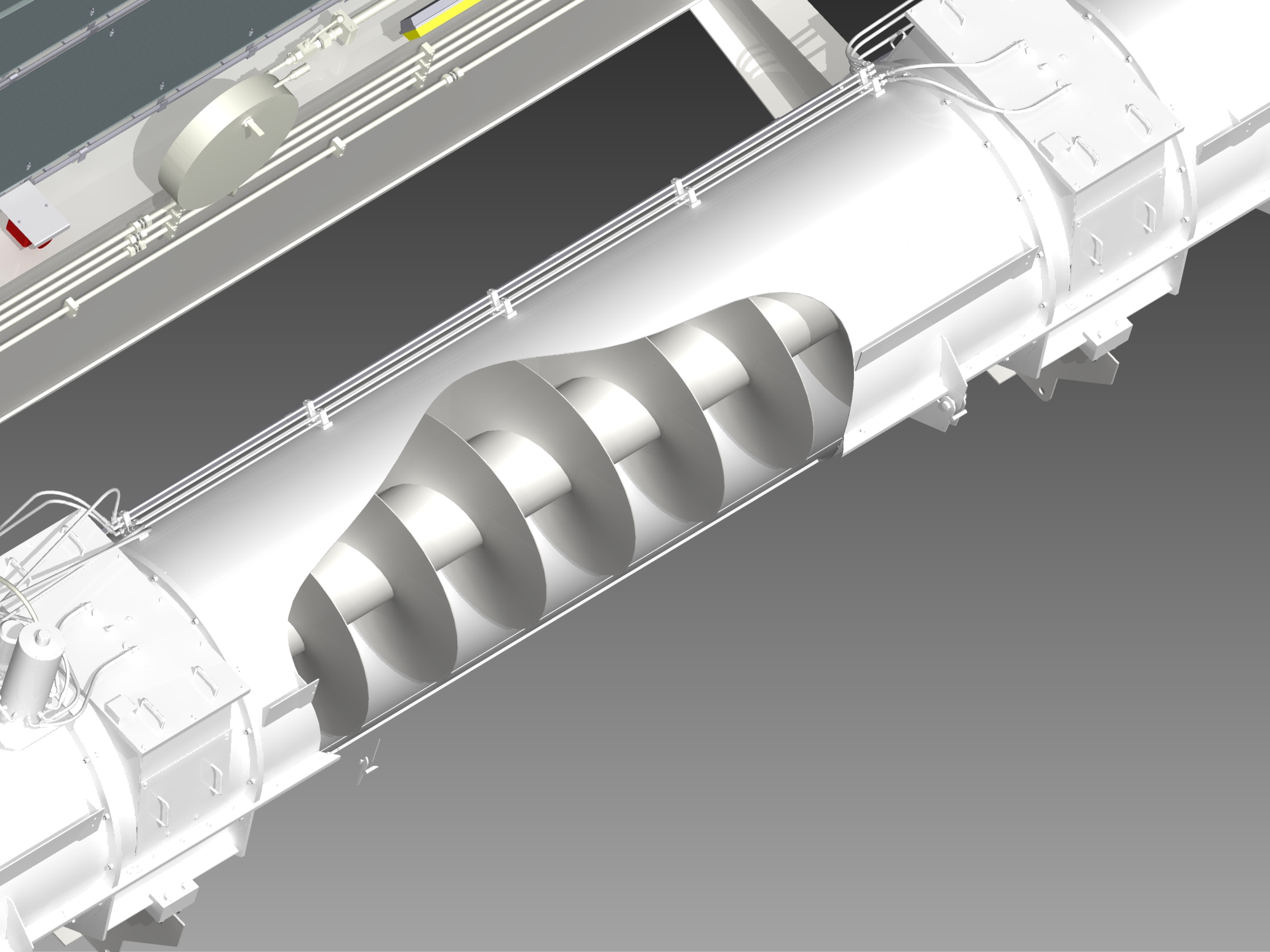

Vertical conveyor

The vertical conveyor is a screw-type device which elevates bulk material from below the cargo level in the ship’s hold up to the horizontal conveyor. The totally-enclosed vertical conveyor is built up from standard screw sections, outer tubes and intermediate bearings. It is mounted in a robust supporting steel structure.

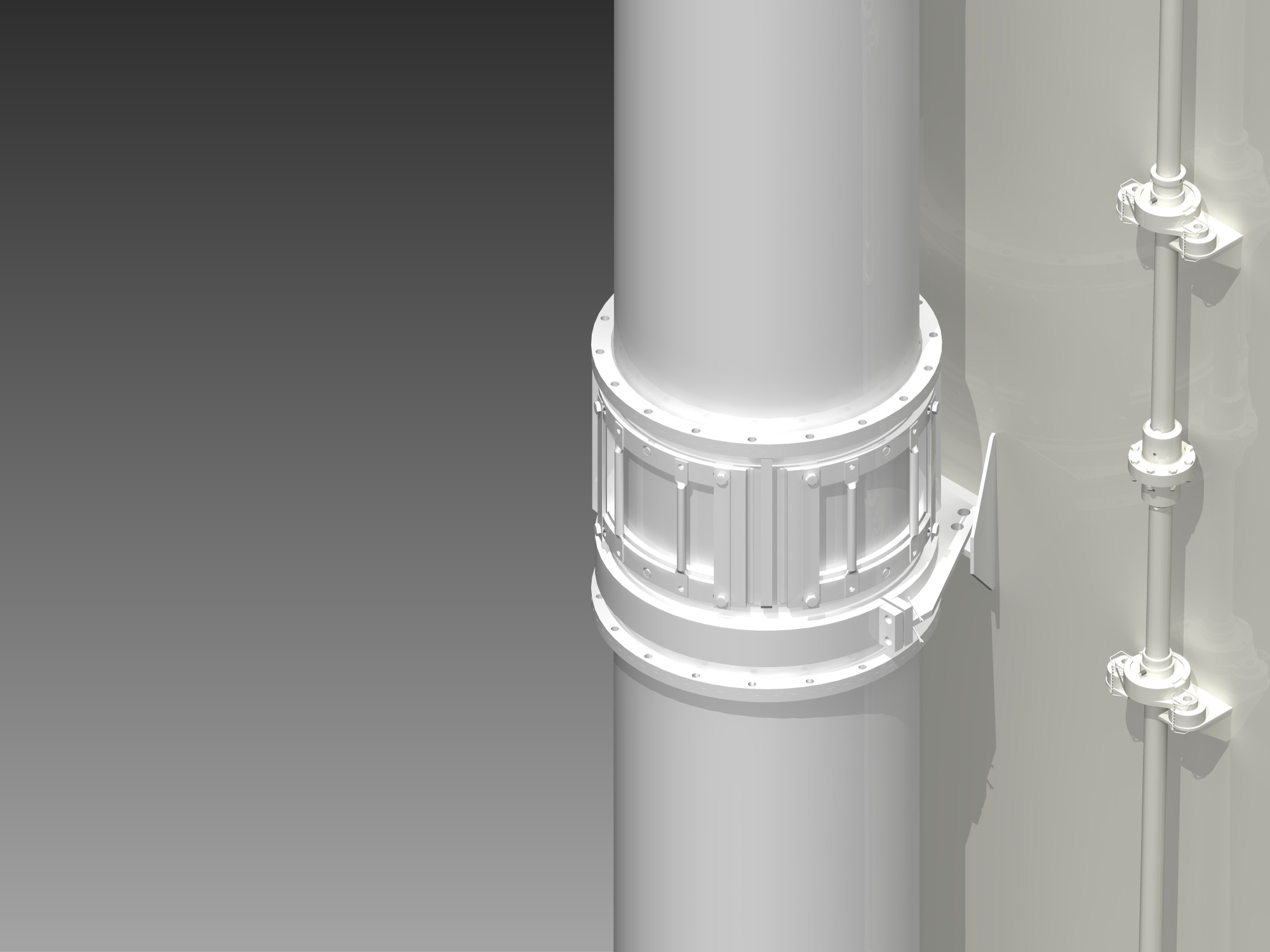

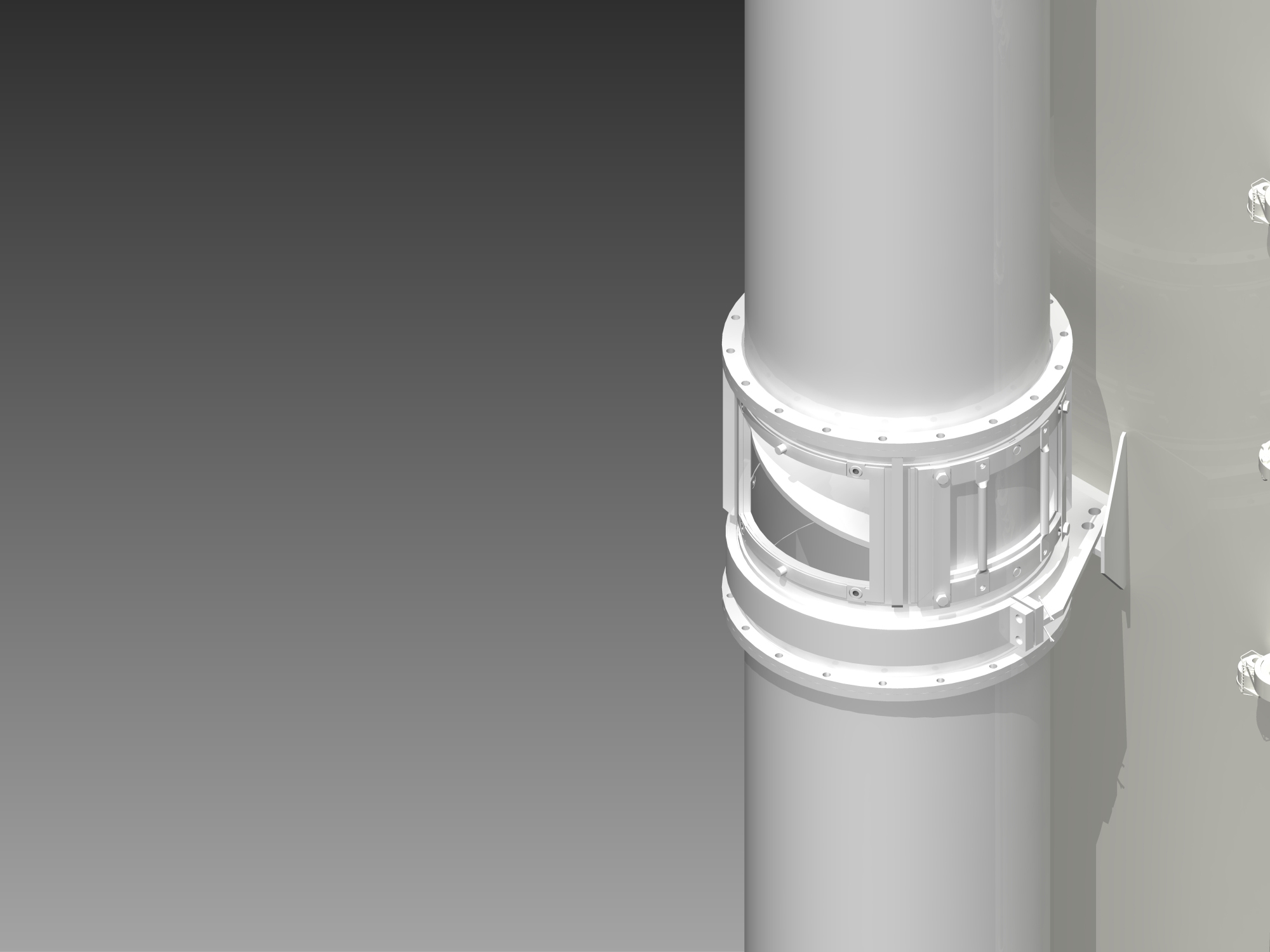

Intermediate bearing

Siwertell designed the unique Outer Diameter (OD) bearing to achieve a continuous screw flight for the vertical conveyor without any interruptions. A continuous screw reduces power consumption and minimizes the risk of material getting stuck in the tube.

Auxiliary hoist

Heavy items such as pay loaders and excavators are often used in the holds to assist the unloader during the final clean-up phase. A wire rope hoist, installed on the horizontal arm, is used for lifting equipment in and out of the hold.

Horizontal conveyor

The horizontal conveyor is normally a screw-type conveyor. Mounted on the horizontal boom steel structure, it receives bulk material from the vertical conveyor via an enclosed transfer chute. It then transports material to a vertical discharge chute in the center of the slewing turret. For some applications an enclosed belt conveyor is used instead of a screw conveyor.

Electrical system

The electrical system is installed in an insulated electrical housing equipped with a heating fan and an air-conditioning unit. It is made up of elements such as low voltage switchboards with a motor control center, contactors, a programmable logical control-system and the human machine interface.

Operator's cabin

The unloader can be operated either from the cabin or using a remote control unit directly from the side of the ship’s hold. Both arrangements offer excellent views of the unloading area. The cabin is mounted on an arm at the same level as the horizontal arm and it slews along with the horizontal arm. It is fully-insulated and equipped with a heating fan and an air-conditioning unit to provide the operator with a comfortable work place, even in extreme weather conditions.

Bruks-Siwertell

Bruks-Siwertell