Hammer mill (system solutions)

Back to Grinding & Milling

Optimized operations deliver outstanding performance

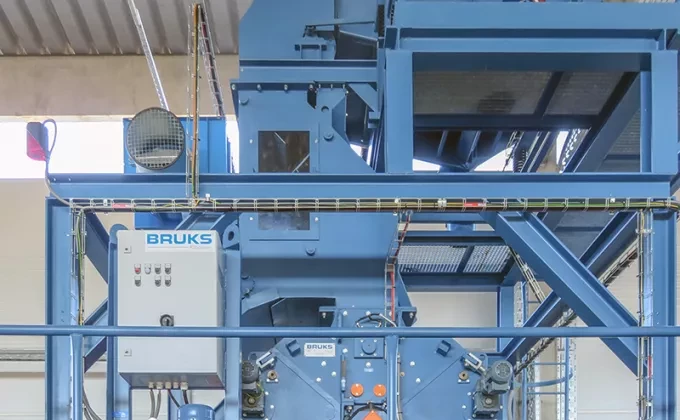

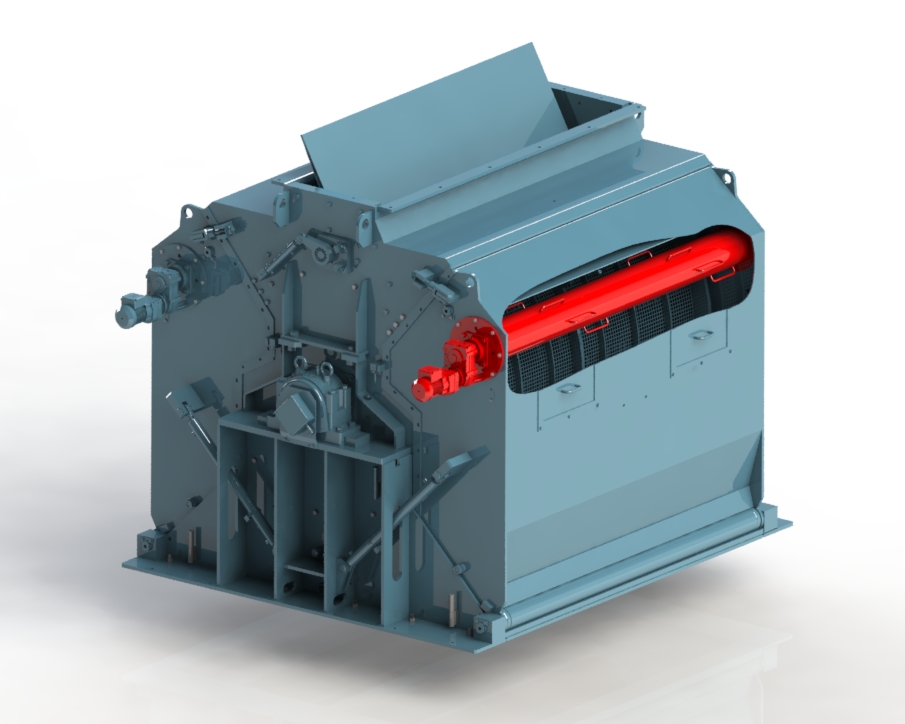

Our hammer mills can be arranged as individual units, but for large-scale wood-processing requirements they can be delivered as a system solution; configured in groups to deliver outstanding performance.

Multiple mills can work seamlessly together in a synchronized operation with a controlled feed rate that automatically adjusts to changing conditions, and therefore optimizes through-put.

Decades of development

Our entire hammer mill range is based on decades of development and customer-driven enhancements, making our hammer mill technology extremely effective for the wood-processing industry. When coupled with the ability to fully-synchronize multiple mills into a single system, this can deliver distinct commercial advantages.

Our multi-unit systems comprises both dry and green wood grinding machines, which each generate valuable wood products for the particle board industry and other wood composite markets, pellet production, briquetting, and boiler fuels.

To ensure minimal environmental impact and to meet local dust-emission standards, our hammer mills can operate with only recycling airflow or an optional external fan system for increased production.

All systems are Atex-classified and meet the highest international safety standards.

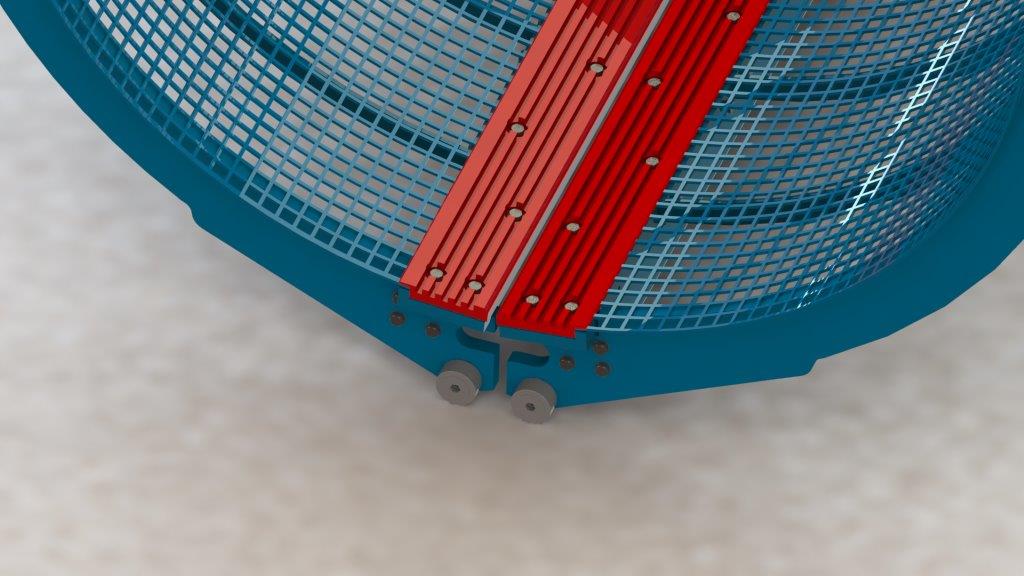

Image: The machine housing has an integrated cleaning device

Image: The screen is clamped with milling segments

Image: Operating unit for safety and maintenance functions

Technical data

-

Type -

HH 300x850 -

Rotor Diameter [mm] -

700 -

Infeed Opening [mm] -

300 x 850 -

Number of Hammers [pcs.] -

144 -

Screening Surface [m²] -

1,2 -

Capacity [t/h]* -

2 - 4 -

Motor Power [kW] -

75 - 110 -

Weight [kg]** -

1 400

-

Type -

HH 300x1.200 -

Rotor Diameter [mm] -

700 -

Infeed Opening [mm] -

300 x 1.200 -

Number of Hammers [pcs.] -

216 -

Screening Surface [m²] -

1,6 -

Capacity [t/h]* -

3 - 6 -

Motor Power [kW] -

110 - 160 -

Weight [kg]** -

1 600

-

Type -

HH 400x1.500 -

Rotor Diameter [mm] -

1 000 -

Infeed Opening [mm] -

400 x 1.500 -

Number of Hammers [pcs.] -

216 -

Screening Surface [m²] -

2,9 -

Capacity [t/h]* -

5 - 10 -

Motor Power [kW] -

160 - 250 -

Weight [kg]** -

5 500

-

Type -

HH 500x1.800 -

Rotor Diameter [mm] -

1 300 -

Infeed Opening [mm] -

500 x 1.800 -

Number of Hammers [pcs.] -

316 -

Screening Surface [m²] -

4,6 -

Capacity [t/h]* -

8 - 18 -

Motor Power [kW] -

250 - 400 -

Weight [kg]** -

9 500

-

Type -

HH 600x2.000 -

Rotor Diameter [mm] -

1 600 -

Infeed Opening [mm] -

600 x 2.000 -

Number of Hammers [pcs.] -

480 -

Screening Surface [m²] -

7,6 -

Capacity [t/h]* -

15 - 25 -

Motor Power [kW] -

400 - 630 -

Weight [kg]** -

15 000

| Type | Rotor Diameter [mm] | Infeed Opening [mm] | Number of Hammers [pcs.] | Screening Surface [m²] | Capacity [t/h]* | Motor Power [kW] | Weight [kg]** |

|---|---|---|---|---|---|---|---|

| HH 300x850 | 700 | 300 x 850 | 144 | 1,2 | 2 - 4 | 75 - 110 | 1 400 |

| HH 300x1.200 | 700 | 300 x 1.200 | 216 | 1,6 | 3 - 6 | 110 - 160 | 1 600 |

| HH 400x1.500 | 1 000 | 400 x 1.500 | 216 | 2,9 | 5 - 10 | 160 - 250 | 5 500 |

| HH 500x1.800 | 1 300 | 500 x 1.800 | 316 | 4,6 | 8 - 18 | 250 - 400 | 9 500 |

| HH 600x2.000 | 1 600 | 600 x 2.000 | 480 | 7,6 | 15 - 25 | 400 - 630 | 15 000 |

*depending on kind and dimensions of material, moisture content and screen size

**only hammermill without a motor/cleaning/feeding device

Bruks-Siwertell

Bruks-Siwertell