Environmental aspect of ESG; our focus on climate change, pollution and waste

Focus areas

- Product development

- Reduce climate impact

- Reduce energy consumption

- Reduce waste

We strive to reduce the environmental impact of products throughout their entire lifecycle, in development, design, manufacturing, and use, through to recycling. Our high-quality products have long service lives with minimal requirements for maintenance. They are designed to protect working and external environments where the equipment is used and where the business impacts the environment through airborne emissions, the generation of waste and noise.

We are committed to minimizing the release of dust into the air and water. Our systems have previously won the prestigious International Bulk Journal (IBJ) Environment Protection Award, which is annually awarded to organizations that have contributed to reducing emissions in ports or at sea.

"50% - Our target to reduce greenhouse gas emissions by 2030"

Reduction of dust emissions

Minimizing the spread of dust has long been central to our product development. Dust occurs naturally when handling bulk materials.

A dry bulk commodity is either intrinsically dusty, like powdery cargoes, or dust can be generated from material degradation, which produces small particles called fines. The more carefully material is handled, the lower the percentage of fines in a load. It is therefore important that equipment is designed to minimize material degradation and prevent delicate cargoes from disintegrating. The benefits of this are many: material losses are minimized, as well as the need for cleaning a plant and its machinery; air quality and the working environment are improved for personnel; risks of heat generation and fire are prevented in a dustfree environment; and the marine environments around port facilities are protected.

Reduce Climate Impact - A systematic approach to ambitions

Bruks Siwertell is working to reduce its green- house gas (GHG) emissions throughout the value chain. Today, parts of the Group’s carbon footprint are reported according to the guidelines in Greenhouse Gas Protocol scopes 1 and 2.

The GHG Protocol establishes a global stan- dardized framework to measure and manage greenhouse gas emissions. Direct GHG emissions occur from sources that are owned or controlled by the reporting company and indirect GHG emissions are those that are a consequence of the activities of the reporting company, but occur at sources owned or controlled by another company, such as suppliers.

The GHG Protocol categorizes these direct and indirect emissions into three broad scopes:

Scope 1: all direct GHG emissions

Scope 2: indirect GHG emissions from consumption of purchased electricity,

heat or steam

Scope 3: other indirect emissions, such as the extraction and production of purchased materials and fuels, transport-related activities in vehicles not owned or controlled by the reporting company, 2021 electricity related activities not covered in Scope 2, and outsourced activities, such as waste disposal.

In 2023, each company within Bruks Siwertell Group will carry out climate calculations throughout their operations, both upstream and downstream, and include direct and indirect emissions. This will enable us to prioritize actions in the areas where they can do the most good.

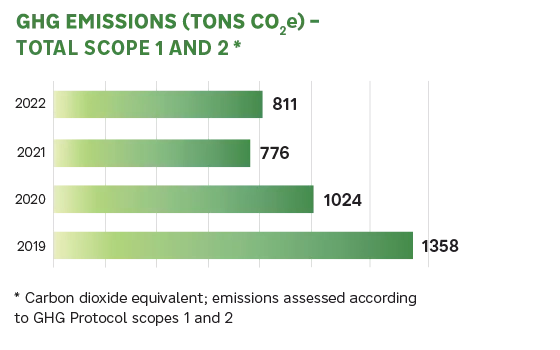

Bruks Siwertell has set a target of reducing greenhouse gas emissions by 50% by 2030, compared to a base-level established in 2019. In 2023, all climate calculation goals will be broken down and set, signaling our climate ambitions and the prioritization of climate efficient solutions.

Bruks Siwertell’s carbon emissions (scopes 1 and 2) have decreased between 2019 and 2022. The change is a result of ongoing initiatives to replace fossil fuels with renewable alternatives and to improve the energy efficiency of operations, but it is also a result of outsourcing some production activities.

Making a positive impact

We serve numerous industries across the dry bulk handling, wood processing and forestry sectors. Within each of these, multiple material types are handled and processed for a variety of customers. Across this diverse industrial base, our ambition is to make a positive impact and to support customers to do the same.

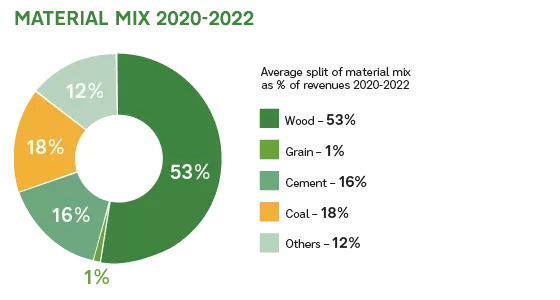

Diversification is part of our business strategy, and over the past three years we are happy to note a broad range in our material segments. Wood is the material that we handle most of, and is our biggest market segment. It is where we benefit from the greatest levels of vertical integration, as across the Group, we have a huge knowledge base, cross-sector expertise and technology.

A significant proportion of global biomass comes from wood and wood-based products including logs, wood chips, waste wood residues, bark and hogged fuel, and sawdust. Our wood-processing and handling technology supports every part of the biomass logistics chain, from its waste form to the final pellet, making it an integral component in many biofuel and bioenergy installations.

We recognize that some of the industries that we serve, and some of the materials that our equip- ment handles, carry higher environmental loads than others, such as coal. Despite its known impact on the environment, coal is still a major dry bulk cargo, traded all over the world for use in industrial processes such as steelmaking and power plants. Bruks Siwertell Group believes that, through our equipment, services and technological capabilities, we can help our customers decrease their environmental impact when handling coal.

For example, our technology handles coal in a way that absolutely minimizes the environmental impact of its ship to shore link. For this, we mean using enclosed systems that minimize dust and eliminate spillage into the surrounding environment. Spillage on the levels encountered through using open handling systems, such as grab cranes, can lose up to 2% of a shipment; we believe that waste on this scale is unacceptable.

We have also enabled operators to switch from handling coal to renewable biomass pellets for energy production. Our specially designed ship unloaders and loaders are able to handle multiple materials, efficiently and safely supporting coal-fired power plants with co-firing – burning coal and biomass – through to their complete transition to only burning biomass.

Furthermore, biomass pellets are fragile, and break down if not handled correctly. They are also very dusty and prone to self-ignite. Our totally enclosed equipment is capable of mitigating these risks, and minimizing any material degradation. This maintains the quality of the shipment and its combustion efficiency; additional environmental gains.

Climate calculation pilot project at FTG Cranes

Between 2021 and 2022, a climate calculation pilot project was carried out by one of our forestry sector companies, FTG Cranes, based in Bäckefors, Sweden. It revealed some interes- ting results. The site manufactures forestry technology including trailers, and the pilot project revealed that the supply of wheels, rims and tires, for example, had almost as much environmental impact as all the steel in the equipment.

Thanks to this climate mapping, we now have climate-impact control of the components of

over 90% of all materials and subcomponents in FTG’s products and can set goals and plan further activities based on these results, including which design solutions are the most material efficient and which should be allowed to act as role models in continued product development. Furthermore, the experience gained from this pilot project will be used to scale-up climate mapping in 2023.

“The result surprised us! Wheels, rims and tires had almost as much environmental impact as all the steel. Thanks to the climate mapping, we have detailed knowledge about more than 90% of all materials and subcomponents in our products and can now start to set goals and plan further activities based on these results”

Ulf Godtman, Quality and Sustainability Manager, FTG Cranes

Reduce energy consumption - Advocating the use of renewable sources

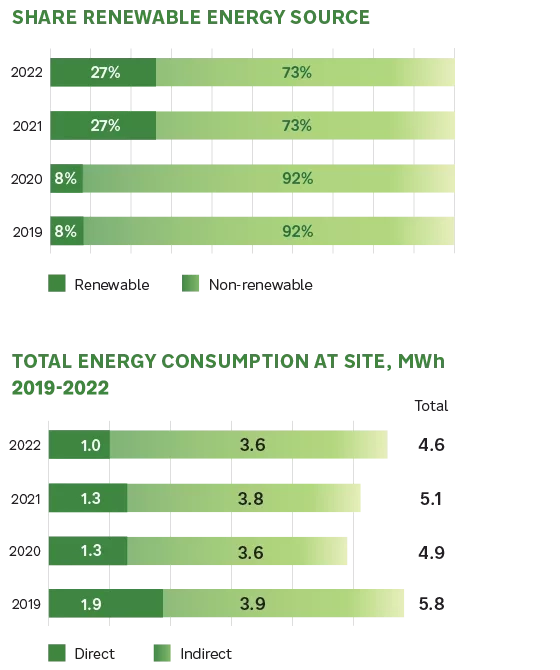

Bruks Siwertell’s operations involve the consumption of energy in production, in offices and transportation. It is important that operations are conducted in an energy-efficient way, but also that the energy source is evaluated with regard to its environmental impact. Work is underway to review electricity consumption by installing energy-efficient lighting and appliances in all offices and advocating renewable energy sources where possible. These measures have resulted in a reduction in the Group’s electricity consumption. The Group has also continued the phasing out of heating oil, in favor of certified renewable electricity. Despite the increase in our business activities during 2022, our total energy consumption, measured in MWh, has reduced by 8% since 2021.

Reduce waste - Implementation of circular initiatives

Reducing the amount of waste, managing waste correctly and seeking circular solutions are important to reduce the overall environmental impact of the business and are therefore priority issues for Bruks Siwertell.

In terms of waste management at an office unit-level, internal knowledge-raising initiatives, such as training on waste sorting and waste management, are regularly carried out. Geographical conditions differ significantly and the degree of maturity varies between different countries globally. Bruks Siwertell has therefore started to look for solutions where the waste contractor can be a partner, who in addition to the management of existing and relevant waste fractions, can also offer functions for measurement, follow-up and development.

When it comes to delivered products and systems, priority is given to a comprehensive service that ensures customers get the most out of each investment. Our service teams carry out repairs and maintenance to extend the service life of equipment and contribute to a reduction in waste. Service teams also ensure that customers understand how equipment is best operated and maintained, with optimal settings that lead to energy savings.

Some of Bruks Siwertell’s products are also designed so that they can be returned, refurbished and resold, ensuring that they meet the same high standards of quality, performance and energy efficiency as when they were new. This contributes to increased circularity as the service life of equipment is extended.

"0% - Our target for waste in our office units"

Bruks-Siwertell

Bruks-Siwertell