Archimedes’ Screw, Bruks Siwertell’s inheritance

2 Oct 2019The ordinary human mind is captivated by the idea that inventions arrive like lightning bolts, and that the history of human innovation can be boiled down into a sequence of ‘Eureka!’ moments. It is a compelling narrative, familiar to anyone who has heard the legend of Thomas Edison and his lightbulb. But this actually comprised a lineage of at least six other inventors. Arguably, Edison’s greatest invention was the commercial research and development lab; the Edison General Electric Company enabled the development of 1,093 patents over the course of his lifetime.

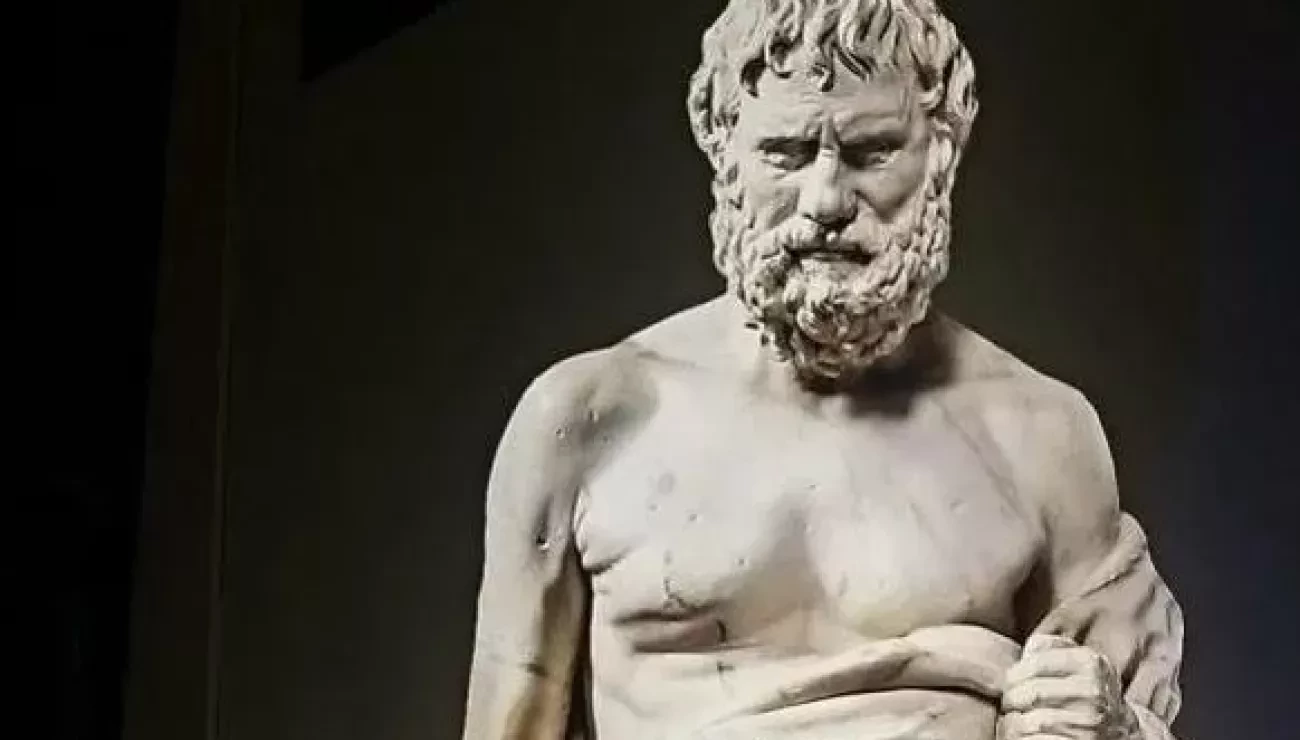

Innovation, therefore, is far more often a sequence of small steps. But the conclusions are no less exciting. At some point during the lifetime of Archimedes of Syracuse, between 287 BC and 212 BC, the mechanical screw, a device for carrying low-lying water upwards, was introduced to Hellenic Greece. Though originally credited with its invention, historians now maintain that Archimedes merely refined it, applying it to the emptying of bilge water from ship hulls. It is in this continuity that Siwertell’s own founders, Olle Siwersson and Gunnar Tell, who combined their surnames to give the brand its famous name, took the mechanical screw principle and applied it elsewhere.

Better, bit by bit

The challenge of using a mechanical screw to move dry cargo is that even when powdery, it is difficult to take up into the system in the initial phase, particularly when the cargo level is low. While it does work eventually, a lot of time and energy can be wasted in this early stage.

“So then I had this idea,” said Mr Siwersson, in a 1981 interview. “What happens if you counter rotate the housing against the screw?” At first he made a working model, but before he could progress to ship unloaders, he needed to try his ideas on something larger.

Mr Siwersson decided to install a screw conveyor at a 20m high rape seed silo in Helsingborg where he lived. Lantmännen, the Swedish grain production company that owned the Silo, did not agree to the test, but that did not deter Mr Siwersson. “I managed to sneak in anyway and climbed around on the walls inside the silo to build the Siwertell machine; I actually had to make a hole in one of the silo walls. If they had discovered me, I am sure they would have called the police.”

After some hard work, a 20m-high Siwertell conveyor stood ready inside the silo. Mr Siwersson invited the Board of Lantmännen to come and see how 80 metric tons of rape seed could be conveyed each hour though a 130mm tube.

Not surprisingly the installation was approved in retrospect, and an order for a similar system was placed for Landskrona harbor in Sweden. The story of Siwertell’s enduring success had begun.

From concept to commercial reality

The success of Siwertell screw conveyor technology is based on its unique inlet feeder. The counter-rotating inlet gathers material from the hold and feeds it into the screw mechanism inside. The added rotation of the outer casing stops lumps of cargo collecting inside the mechanism. Olle Siwersson’s and Gunnar Tell’s improvements refined the existing principle of the mechanical screw and made it possible to begin loading cargo immediately without wasting any energy.

Submerging the screw head and its counter-rotating casing beneath the surface of the cargo creates a totally-enclosed system from one end of the vertical conveying arm to the other, preventing cargo from being thrown out of the screw mechanism. This means that rather than a 45-degree angle relative to the cargo’s surface, as Archimedes’ system required, the vertical conveying arm can do its job at a perpendicular angle to the cargo, or move through a +/-30-degree angle, allowing it to unload the whole cargo while saving space on the quay.

Tireless innovation

Mr Siwersson often spoke of his love of invention and how the Siwertell screw was developed. “Maybe I was born an inventor,” he said. “As far back as I can remember I have been constructing different things. I have always had a driving force in me, looking for technical problems and then trying to solve them. But I have learned that you need a whole lot more than this creativity to succeed and live only off your inventions.”

Although their initial work was aimed at the agricultural market, the potential for ship unloading applications was recognized and in 1974, the Siwertell ship unloader was born, along with the company AB Siwertell. Initially situated in the town of Åstorp in southern Sweden, the company later moved to its present location in Bjuv, only a short distance away.

Since its first installation in Landskrona, hundreds of Siwertell ship unloaders now serve the global dry bulk handling market. The ingenious mechanical screw design has been applied to many different types of ship unloaders, tailoring capacities and capabilities for a diverse range of cargoes including biomass pellets, sulfur, cement, coal, fertilizer, grain, alumina, and many more.

Siwertell has developed machines which are fire and explosion-proof for handling volatile cargoes like sulfur and biomass; others, stowed on a truck trailer, can be unpacked and operational within an hour. Some Siwertell unloaders are sound-proofed to meet local noise pollution requirements; elsewhere, lightweight models allow for low load on quaysides. Others can unload at 3,000t/h, offloading coal at nearly a metric ton every second.

Just as Edison did not actually invent the lightbulb, Olle Siwersson and Gunnar Tell did not invent the vertical screw. But like Thomas Edison, and Archimedes before him, they took an already established concept, applied it for a new purpose, and refined it further. Today, Bruks Siwertell’s team of engineers do the same, inventing incremental improvements and upgrades that bring additional function, enhanced efficiency and performance, and reduced downtime to the device at the core of the Siwertell ship unloader: the 2,300-year-old Archimedes Screw.

Bruks-Siwertell

Bruks-Siwertell