Bruks Siwertell launches next generation drum chipper

21 May 2025

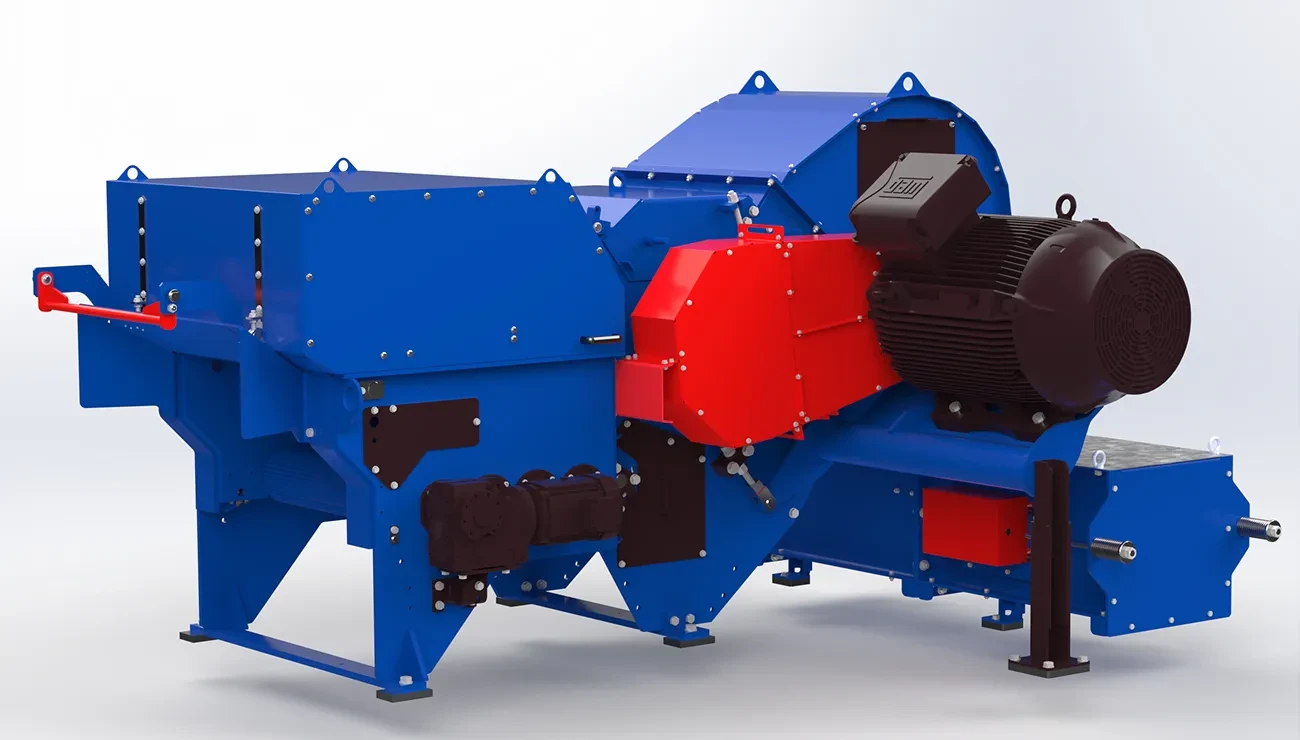

Bruks Siwertell company, Bruks Klöckner, has launched a next generation industrial drum chipper, which delivers enhanced performance and increased efficiency, setting a new benchmark in drum chipping technology for handling sawmill byproducts and waste wood.

The next generation DH 365 is an advanced development of Bruks Klöckner’s proven drum chipper model. “For years, the DH 365 has been a trusted solution for sawmills, delivering high-capacity, precision chipping of waste wood,” says Patrick Wicharz, Area Sales Manager, Bruks Siwertell. “Now, with strategic design modifications and cutting-edge advances, the next generation DH 365 offers a number of enhancements and features that are specifically tailored to offer customers a step change in chipping performance, efficiency, and ease of use.

“With no steel frame or pit required underneath the machine, the discharge conveyor arrangement can be at ground level, which delivers significant cost savings and installation benefits for customers, and improves accessibility for maintenance,” Wicharz explains. “Water and debris can collect in pits, leading to rust issues, if you remove the pit, you remove the problem.

“Furthermore, the next generation DH 365 offers a broad range of wood chip lengths from 19mm to 36mm, so customers can tap into various markets, depending on what chip length is required.”

Other key innovations in the new industrial drum chipping model are an enhanced hydraulic system, which has a double-action hand pump. This allows the hood to open more quickly and efficiently as force is generated on both the up and down stroke of the lever. Also, a standard solenoid valve replaces the hydraulic block, ensuring smoother hood closure, free from judders.

The chipper’s new cradle design, with a larger drive shaft and optimized chain drive, prevents material from being drawn into the cradle frame. This eliminates operational issues, reduces the risk of drive shaft damage and enhances machine durability.

Bruks Klöckner offers two types of infeed rollers with the next generation DH 365 model. As standard, the unit is fitted with extremely robust, single-pieced infeed rollers with serrated surface-hardened steel teeth for a powerful infeed, and as an option, the infeed rollers can also be segmented, depending on operational requirements.

The DH 365 is specifically designed for processing sawmill waste wood, handling material with a maximum infeed diameter of 250mm. It is available in two configurations and inlet widths: the DH 365 x 560mm, which offers a capacity of 20 to 60 sm³/h and a drive power of 55 to 2 x 90kW; and the DH 365 x 825mm, which offers a capacity of 30 to 90 sm³/h and drive power of 90 to 2 x 132kW.

“These design updates, advances and optional configurations, including the ability for sawmills to substantially adjust the chip length, means that this new model industrial drum chipper can be greatly tailored to benefit a customer’s specific needs, application and market demand; it really stands apart,” adds Wicharz.

The next generation DH 365 drum chipper will make its official debut in Hanover, Germany, at LIGNA 2025, a leading global trade fair for woodworking and wood-processing technology. To witness the power and innovation of the next generation DH 365 drum chipper firsthand, join Bruks Siwertell between May 26 to 30, Hall 25, Booth H66, at LIGNA 2025.

For more information, please contact us

Bruks-Siwertell

Bruks-Siwertell