Bruks drum chipper boosts US veneer operations

24 Nov 2025

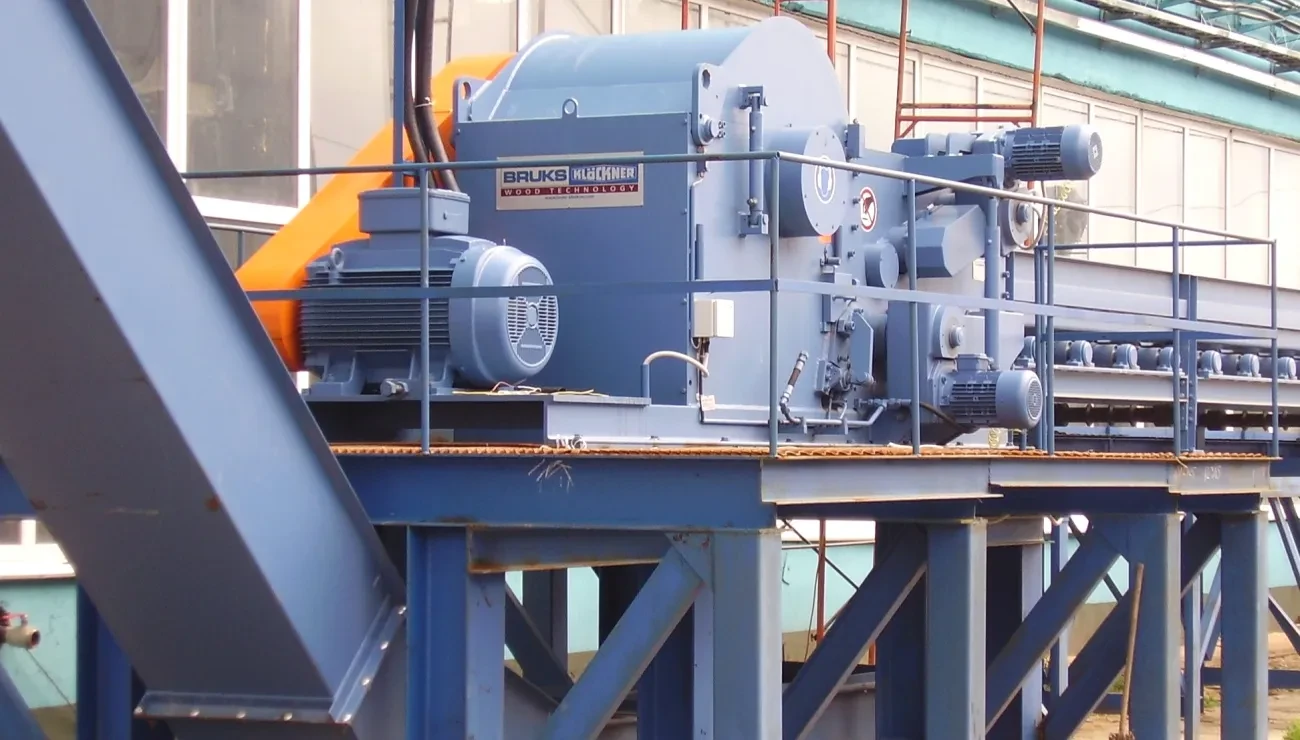

Bruks Siwertell has delivered a new high-capacity Bruks veneer drum chipper to Veneer Technologies based in Newport, North Carolina, USA. It was ordered to ensure high levels of operational reliability, as well as to improve capacity and material flow.

“Veneer Technologies is a long-standing Bruks Siwertell customer, already operating a Bruks veneer drum chipper, which has provided over a decade of reliable service,” explains Mike Curci, Vice President Sales, Bruks Siwertell. “This proven performance played a key role in the company’s decision to select our industrial drum chipping technology again.

“The new Bruks machine has replaced an existing chipper from another manufacturer,” adds Curci. “Although not as old as the original Bruks chipper, the operator’s other chipping unit has needed to be rebuilt three times in the past year, and was causing repeated plugging issues.”

To ensure a rapid, smooth transition when switching from the old to the new chipper system, the DH-V 200/300 × 650 chipper model was integrated with the customer’s existing motor. The installation also presented rare configuration requirement, with the infeed belt positioned in a pit, highlighting the adaptability of Bruks Siwertell’s engineering solutions.

Veneer Technologies is recognized for producing high-quality veneer products tailored to specialized customer needs. “Our veneer drum chippers are built for precision and endurance, contributing to Veneer Technologies’ reputation for high-quality products,” Curci continues. “They are engineered for longevity and reduced maintenance requirements, enabling reliable performance year after year.”

The new chipper was delivered fully shop-assembled in June 2025, and features a top infeed roller that compresses any fluffy or fibrous veneer material before chipping, ensuring a consistent feed and uniform chip size.

For more information, please contact us

Bruks-Siwertell

Bruks-Siwertell