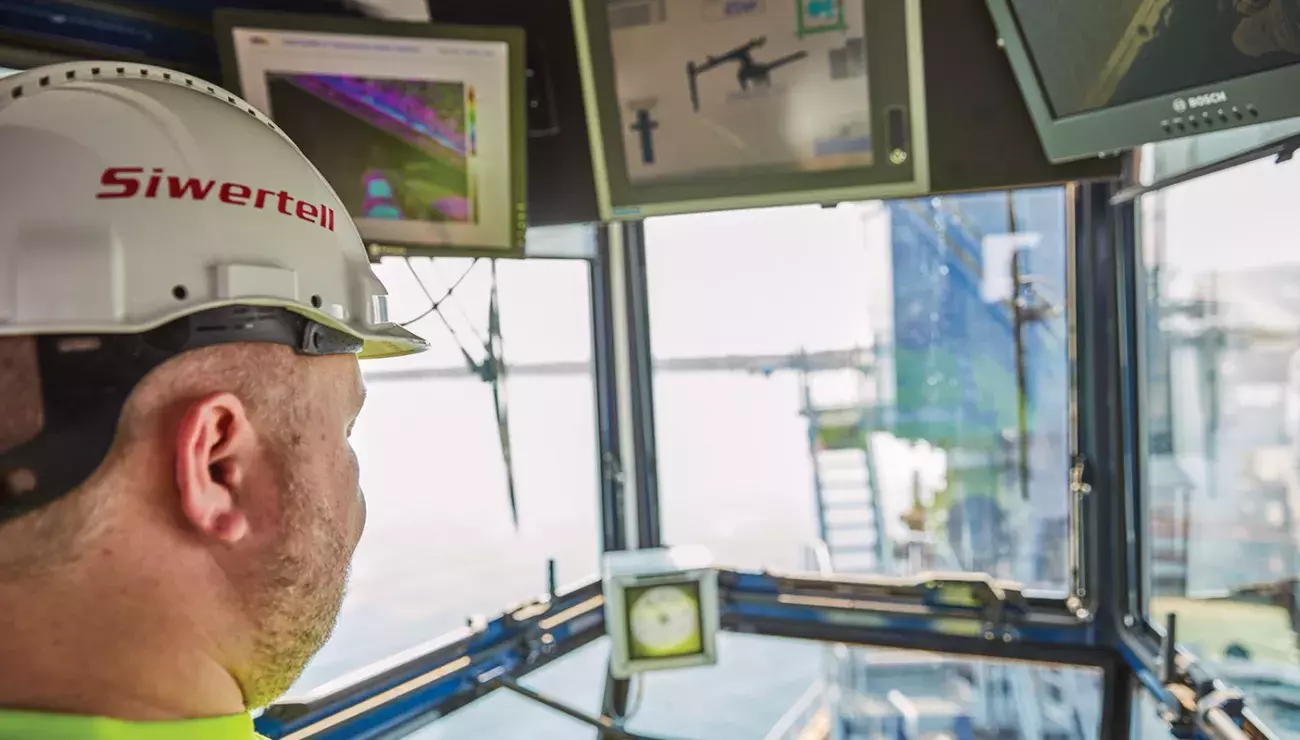

Operator training unlocks unloader potential from day one

13 Jul 2020Good training delivers three crucial elements for any operator: improved safety levels, higher efficiencies and cost savings. This powerful trio drives Bruks Siwertell to ensure that, prior to or once a ship unloader has been delivered, operator training becomes a key area of focus and that it continues to be throughout the service life of the unloader.

“It is not enough just to hand over equipment,” says Örjan Westerberg, Service Contract Engineer, Bruks Siwertell. “It is essential that all operators are trained properly. This increases equipment familiarity, which means that users are not only able to perform routine unloading operations at an expert level, but respond far more effectively in emergency scenarios, as well.

“Also, to ensure the continuity of performance, it is important that everyone who uses the equipment is trained to the same standard,” Mr Westerberg continues. “Depending on how large a terminal is, there might be a significant number of different personnel operating an unloader or multiple unloaders over the duration of discharging a ship. Each has to be as knowledgeable as the next.

“As our Siwertell ship unloaders are tailored for specific operational needs, Bruks Siwertell has matched this accordingly this with customized operator training programs. Their main purpose is to train personnel to operate a ship unloader in a safe way to ensure peak unloading efficiency and extended equipment service life. They also aim to smooth and improve start-up procedures, minimizing the time it takes to bring equipment online,” he says.

Efficient unloading techniques

For example, there are four main techniques when it comes to unloading patterns within a hold – long travel parallels, slewing concentric lines, pendulum parallels and fan-shaped pendulum.

Long travel is the most common and efficient technique for unloading dry bulk material. However, any of these travel patterns can be used. The choice of unloading pattern can be determined by the ship unloader’s mobility, which is, in turn, dictated by hatch cover types, obstacles on the jetty and material characteristics.

“In the long-term, the efficiency and condition of a ship unloader depends on how well the user operates and maintains it,” explains Mr Westerberg. “The position and operating angles of the vertical conveyor arms, unloading schedules, the strategic use of final-stage clean-up vehicles and troubleshooting; all have an impact on an unloader’s efficiency and condition.

“The unloader should be started with the inlet feeder just above the material, and when it starts to rotate, it should be moved directly down into the cargo with the vertical arm in an upright position, at zero degrees. Operations should continue as much as possible in this position. To reach into the corners of a ship’s hold and under hatch coamings it can be operated at an angle of +/- 30 degrees.

“Furthermore, the conveyor arm should be kept moving at all times with the inlet feeder head submerged and its wings not visible, but not too deeply as to cover the complete inlet unit itself, as material could then start to impact the gearbox, which sits a short distance above the inlet feeder.

“It is important to note that the vertical conveyor screw should not run without material in it for long periods of time as this can cause excessive wear and heat build-up; material in the conveyor stabilizes and transfers heat from the vertical conveyor screw set,” Mr Westerberg stresses.

Coordinated EMV operations

“Learning how to coordinate the use of earth moving vehicles (EMVs) such as a payloader, excavator or bulldozer also has a significant impact on through-ship efficiency,” Mr Westerberg continues. “EMV operators collect material and move it into a pile where the conveyor arm can operate vertically. This should be done as early as possible and before cargo levels in the hold are too low. Also, to speed up hold clearance, EMV operators could begin piling up low-level material while the ship unloader operates in another hold.

“It takes time and experience to expertly learn these techniques, and the efficient coordination of unloading together with EMVs, but effective training helps operators get off to the best start possible.

“To ensure that the broadest knowledge base is covered, all our programs consist of both theoretical classroom-based learning and practical hands-on training at an operator’s site, or using a suitable equivalent system at another site.

“The central focus of these sessions is about training personnel to operate an unloader to get the most from it. But we also cover topics such as the mechanics, hydraulics and the electrical system. We also look at troubleshooting. In all areas of training, safety is a key concern and is discussed throughout our programs.”

Passing on knowledge

“It is essential that the delivery of any training ensures that all participants have the ability to learn and absorb the information discussed in the sessions,” he says. “We use experienced trainers to make certain this happens and have a good understanding of participants’ positions and responsibilities within their companies and their level of background knowledge, as this impacts the training.

“The size of the group is also significant and an optimal number is up to eight trainees. All our training programs are scheduled over five days. From our experience this is the ideal set-up to cover all the material and also make sure that the course leader’s attention is not too diluted.

“Training manuals for use during the program are customized specifically for each project and we can, of course, tailor the content and depth of the program to a customer’s knowledge and requirements,” Mr Westerberg concludes.

Benefits of tailored training

Training is tailored to ensure that all customers make the most of their equipment by operating and maintaining it in the right way from installation and throughout its lifetime. Benefits of customized training include:

- The best unloading methods are used depending on the vessels and materials handled

- Unloader runs at peak efficiency at all stages, including final clean-up coordination with earth moving vehicles

- Faster, more effective troubleshooting

- Effective knowledge transfer between operators and maintenance personnel

- Extended service life of machinery

- Reduced downtime

PLEASE CONTACT US FOR MORE INFORMATION

Bruks-Siwertell

Bruks-Siwertell