New model service agreements bring flexible support

8 Sep 2025Like all industries reliant on heavy machinery, in the dynamic and demanding world of wood processing, operational efficiency and equipment reliability are paramount. Recognizing this, and the fact that few customers want exactly the same packages of ongoing service support, Bruks Siwertell’s wood technology division has introduced a new, flexible planned service agreement model.

It is designed to allow customers to select the support that they need and meet the unique requirements of their wood-processing installation, ensuring optimal lifetime performance and longevity of their machinery.

Tailored packages of support

“Bruks Siwertell's commitment to customer-centric solutions is evidenced in its technology and lifetime service support,” emphasizes Jennie Lindh Olsson, Service Account Manager, Bruks Siwertell. “These new model service agreements are structured to provide transparency and adaptability, allowing high degrees of customization to meet the specific requirements of each operation. The form is clear about what the contracts contain and allows us to tailor the contract to the customer's wishes and needs.

“Our service agreements encompass a range of benefits aimed at minimizing downtime and reducing maintenance costs,” continues Lindh Olsson. “They include regular inspections that can be scheduled at a customer’s convenience. Inspections are critical assessments in service support, as an experienced surveyor can often spot issues ahead of time, and prioritize potential problem areas, enabling proactive measures. This can significantly contribute to decreased downtime and reduces maintenance costs.”

Identifying opportunities

Also included in the agreements are periodic reviews with the contract manager; the frequency is dependent on a customer’s needs. They can focus on inspections, spare parts recommendations, and identify opportunities for facility improvements and optimizations.

“Detailed reports, such as post-inspection reports, are available as well. These provide actionable insights, including suggestions for necessary actions, recommended wear and spare parts, and potential facility enhancements,” adds Lindh Olsson.

Other aspects of Bruks Siwertell’s new model agreements include: priority service and round-the-clock telephone support to ensure feedback within one hour, offering peace of mind and swift issue resolution; spare parts inventory reviews and discounts, with contract holders receiving discounts on wear and spare parts, which contributes to cost-effective maintenance strategies; and waived emergency fees, which are typically incurred for emergency call-outs to resolve urgent issues outside of regular working hours.

New model service contracts can also offer maintenance planning, which ensures the proactive planning of interventions and preventive maintenance, helping to anticipate and mitigate potential issues. “Our agreements are available in various levels, each offering different inclusions, discounts, and services,” she highlights. “This allows customers to select the option that best fits their operational and budgetary needs.”

Strategic asset management

“Understanding the financial implications of maintenance is essential for any installation,” explains Lindh Olsson. “As well as ensuring equipment availability, Bruks Siwertell’s planned service agreements aim to reduce lifecycle costs. By avoiding expensive repairs or interruptions through proactive maintenance, customers can achieve significant savings from competitive discounts on parts and services and exemption from call-out fees. This provides operators with a cost-effective maintenance framework.

“Beyond immediate maintenance needs, Bruks Siwertell's service agreements focus on sustainable asset management,” she adds. “Guidance on repairs or modifications aims to extend the service life of equipment, improve energy efficiency, and boost performance. This approach minimizes the need for complete equipment overhauls, promoting sustainability and cost savings.”

A case in point

A notable example of the efficacy of Bruks Siwertell's service agreements is the partnership with Setra Trävaror AB and its Heby Sawmill, located in Uppsala County, Sweden. Established around 1915, the sawmill specializes in producing sawn wood products for industrial customers, construction manufacturers, glulam factories, and timber yards. Approximately half of its products are exported, with the remaining half serving the Swedish market, including 25 percent supplied to Setra’s own units, primarily in Långshyttan, for further wood processing.

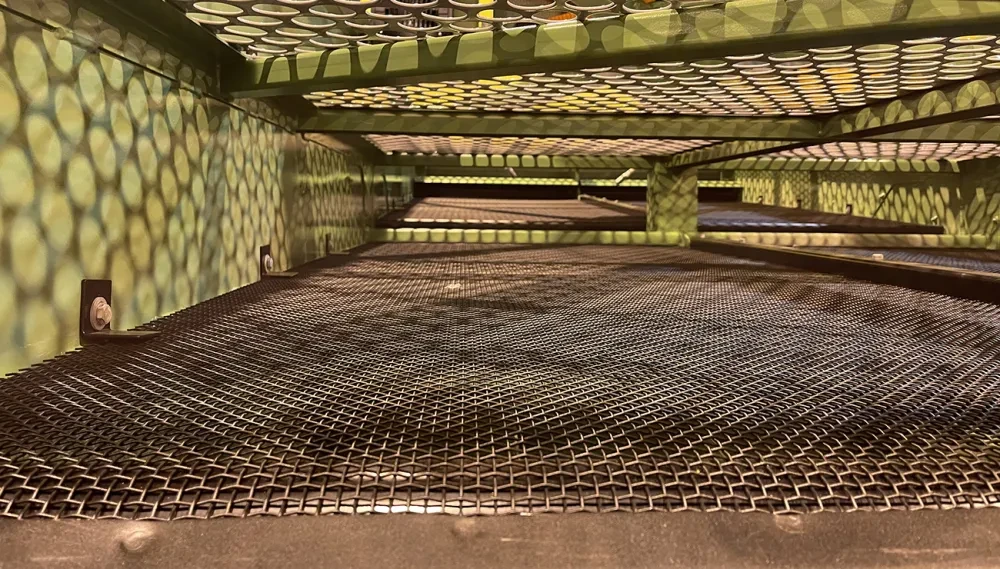

The Heby Sawmill uses a comprehensive suite of Bruks Siwertell equipment, including wood chip screens, vibrating conveyors, drum chippers, a Rotom hammer hog, and screw and belt conveyors. By adopting a tailored service agreement, the sawmill ensures that all machinery operates at peak efficiency, benefiting from the full spectrum of services offered.

Partnerships built on reliability

At the core of all Bruks Siwertell service agreements is a commitment to building reliable partnerships. Each customer is assigned a dedicated service contact for consistent communication and periodic follow-ups.

“We prioritize a safe working environment, collaborative planning of services and actions, and offer prioritized support, ensuring that customers receive the attention and expertise they deserve.

“Bruks Siwertell’s new model flexible service agreements represent a significant advance in supporting the wood-processing industry. By offering tailored solutions that address the specific needs of each customer, maintenance burdens are cost effective and equipment can continue to operate safely, efficiently and reliably. Our customer-centric approach not only enhances an installation’s overall performance, but also strengthens long-term partnerships built on commitment and trust,” concludes Lindh Olsson.

PLEASE CONTACT US FOR MORE INFORMATION

Bruks-Siwertell

Bruks-Siwertell