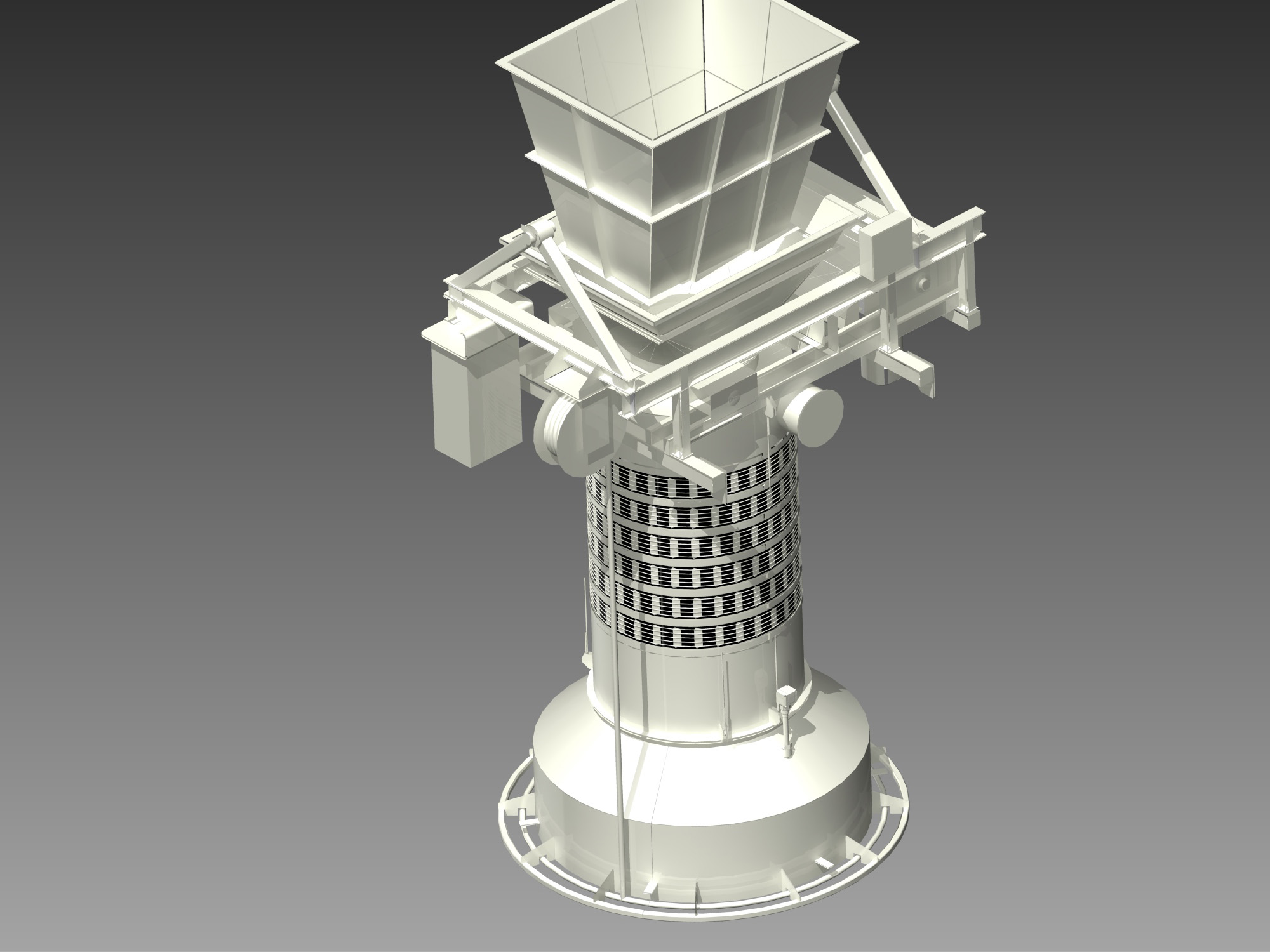

Loading chute

Siwertell ship loaders are equipped with loading chutes appropriate to the materials being loaded. Chutes are often telescopic and their length is automatically-adjusted depending on the level of material in the ship’s hold. They are specially-designed to prevent any dust emissions even when handling powdery, dusty materials.

Operator's cabin

The ship loader can be operated either from the cabin or using a remote control unit directly from the side of the ship’s hold. Both arrangements offer excellent views of the loading area. The cabin is mounted on an arm at the same level as the loading boom and it slews along with the loading boom. It is fully-insulated and equipped with a heating fan and an air-conditioning unit to provide the operator with a comfortable work place, even in extreme weather conditions.

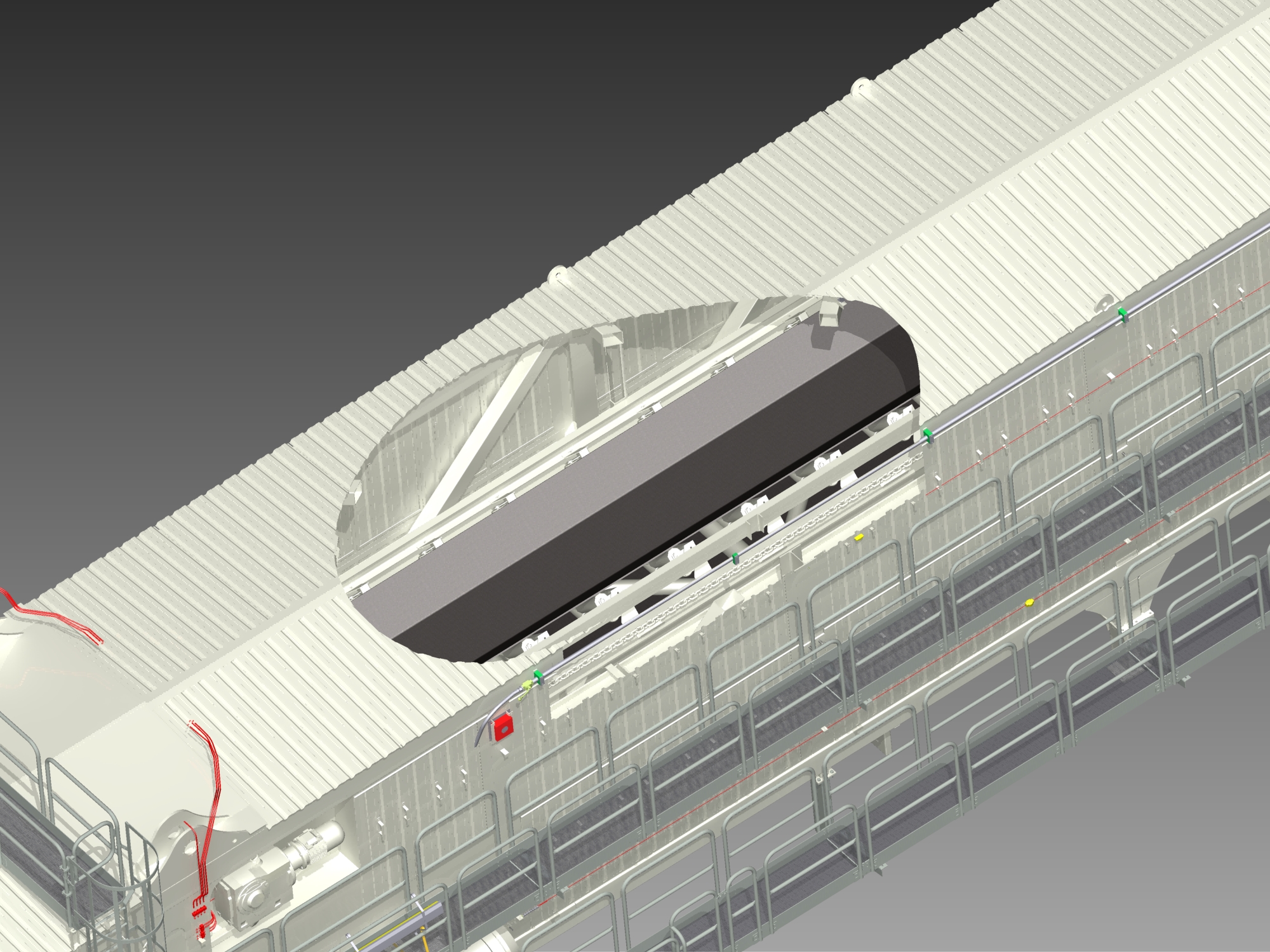

Loading conveyor

The loading conveyor can be screw, aeroslide or belt type; all are totally-enclosed to prevent any dust creation or spillage. When a belt-type conveyor is used, we can offer a telescopic loading conveyor.

Electrical system

The electrical system is installed in an insulated electrical housing equipped with a heating fan and an air-conditioning unit. It is made up of elements such as low voltage switchboards with a motor control center, contactors, a programmable logical control-system and the human machine interface.

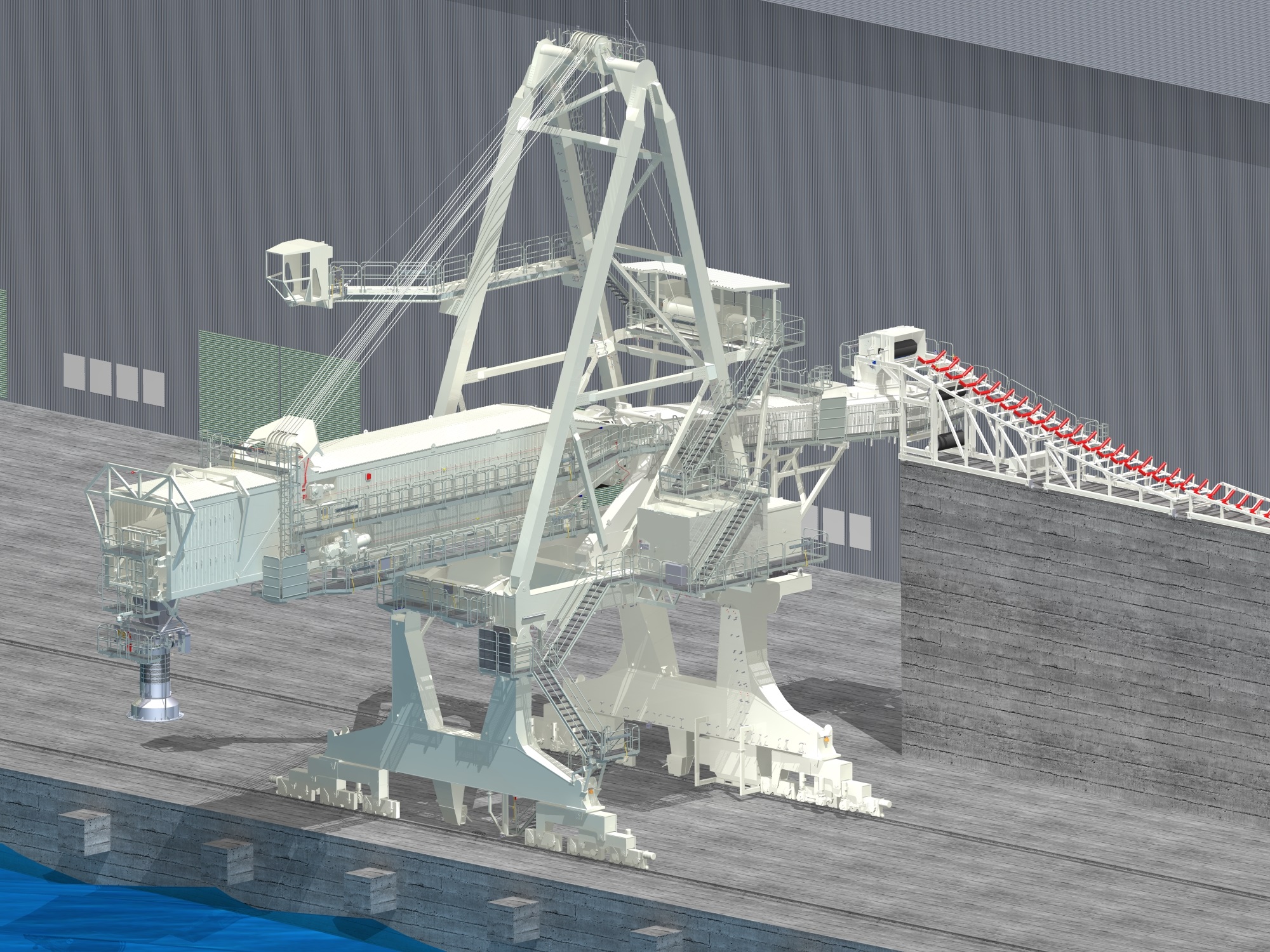

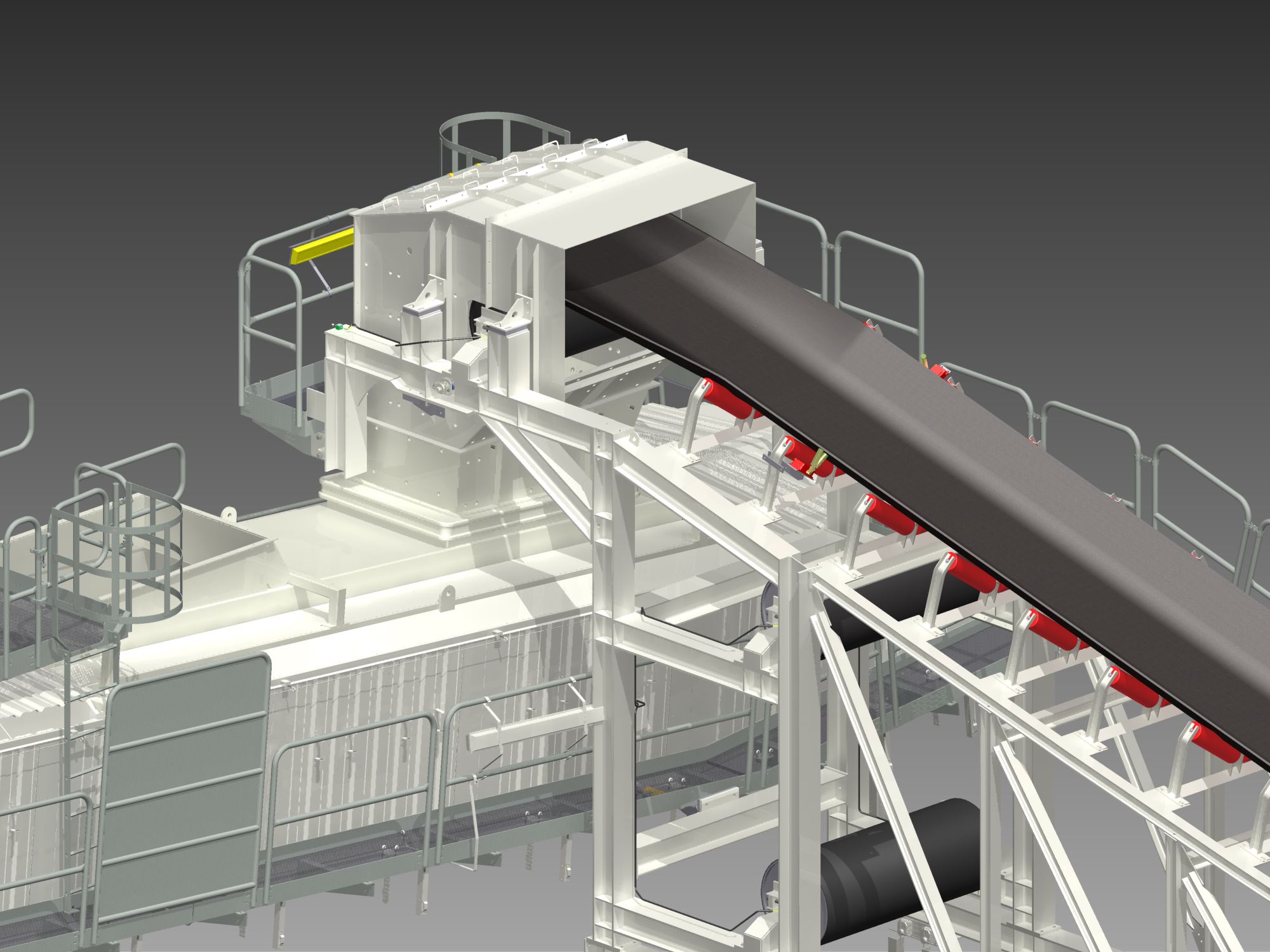

Tripper

A tripper is used to transfer bulk material from the shore conveyor to a traveling ship loader. The tripper travels on rails and is towed by the ship loader.

Bruks-Siwertell

Bruks-Siwertell