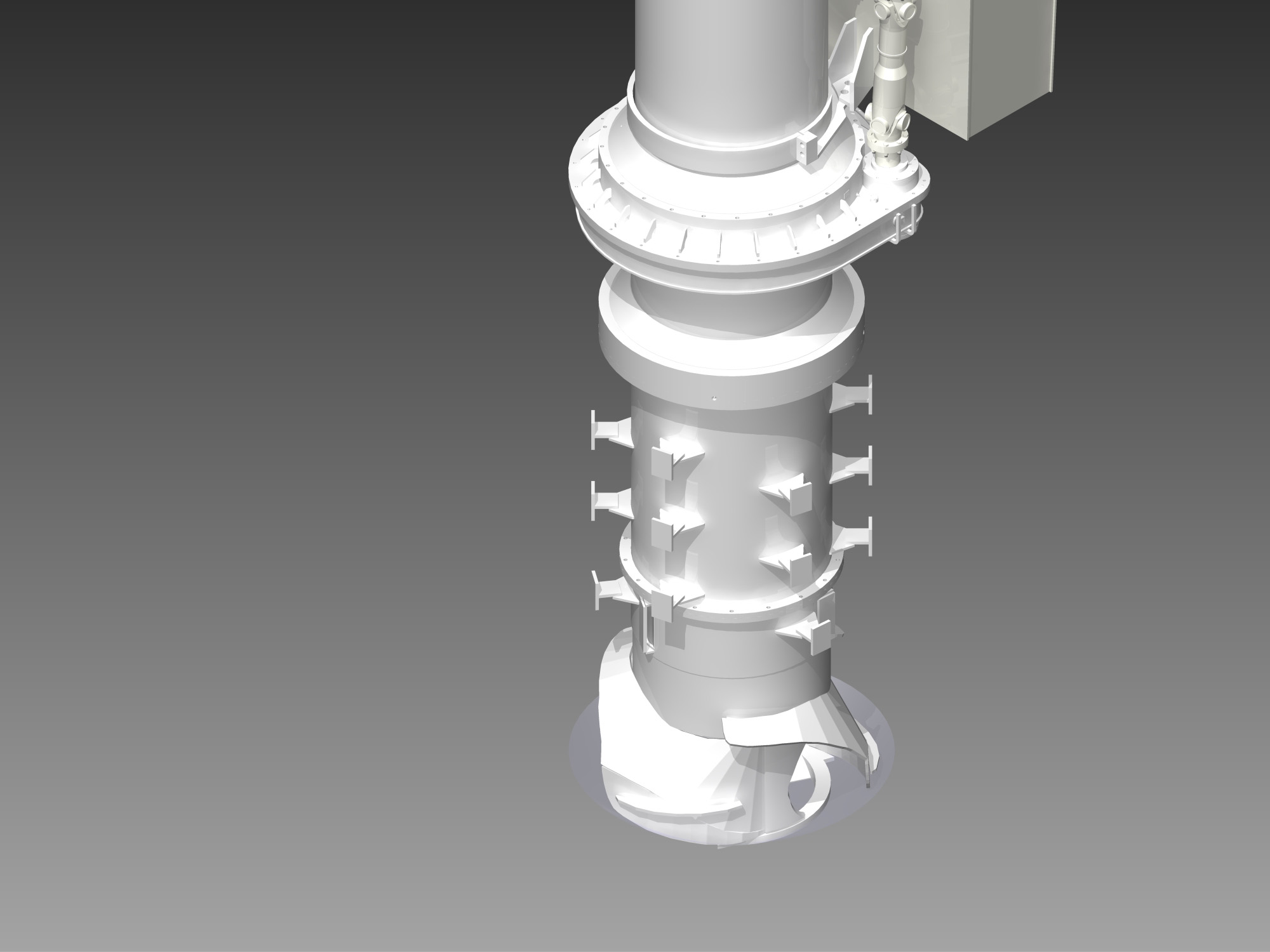

Inlet feeder

The counter-rotating inlet feeder was invented by Siwertell to increase the efficiency of cargo pick-up and the filling factor of the vertical conveyor. It gathers material from below the cargo surface in the ship’s hold to minimize dust creation and then feeds it into the vertical screw conveyor. Different designs of feeder may be used to optimize the unloading performance depending on the material being handled.

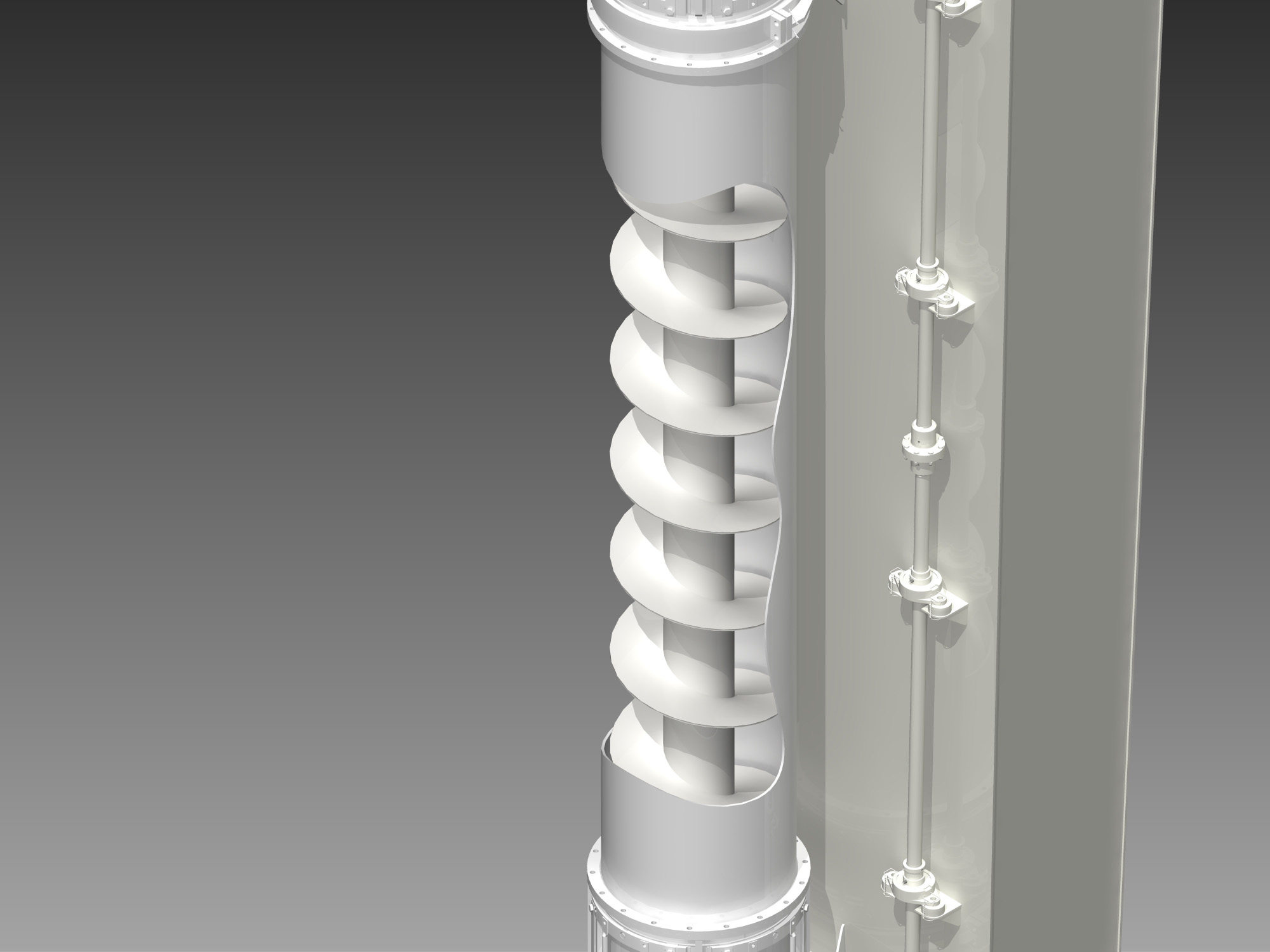

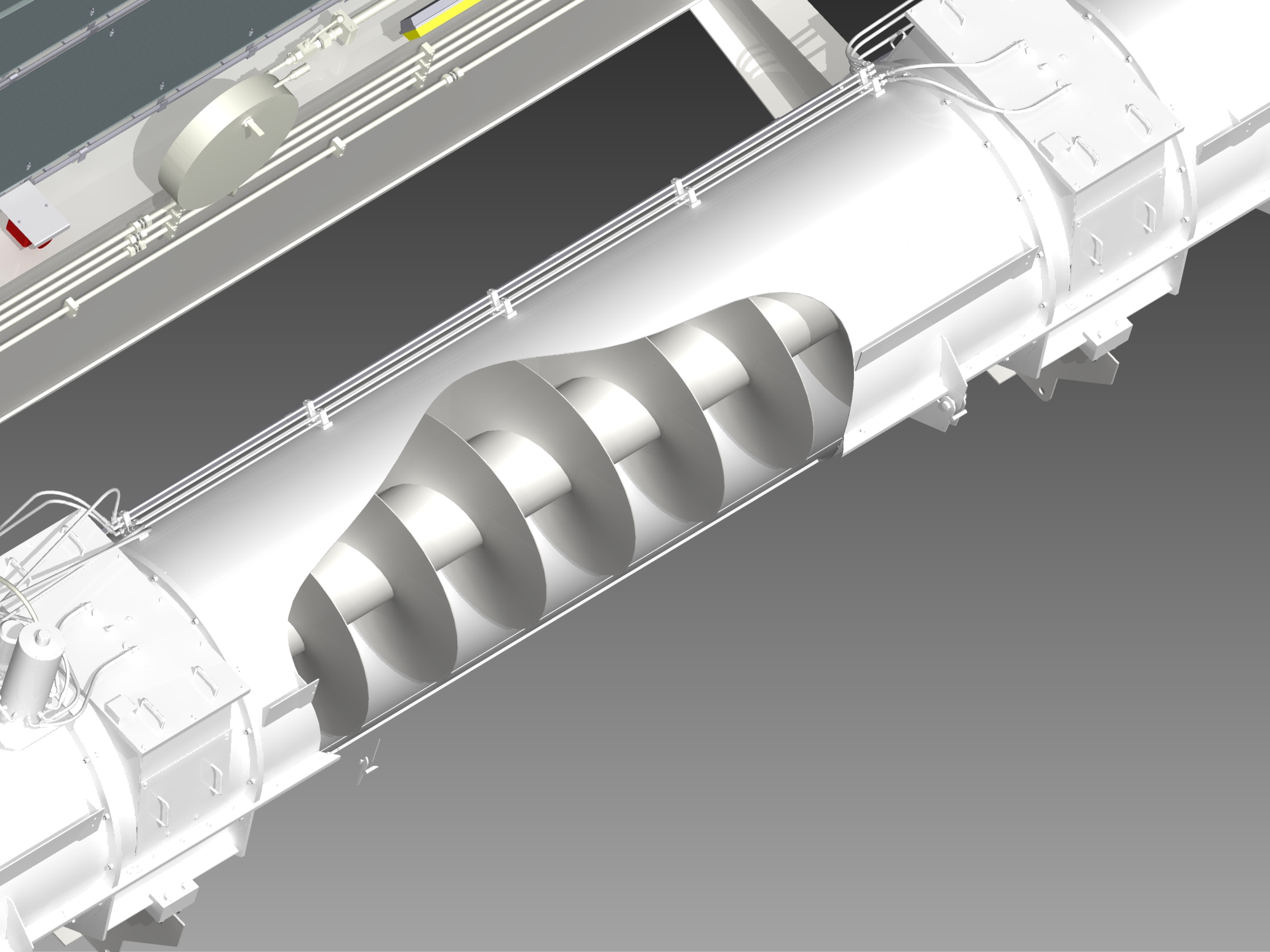

Vertical conveyor

The vertical conveyor is a screw-type device which elevates bulk material from below the cargo level in the ship’s hold up to the horizontal conveyor. The totally-enclosed vertical conveyor is built up from standard screw sections, outer tubes and intermediate bearings. It is mounted in a robust supporting steel structure.

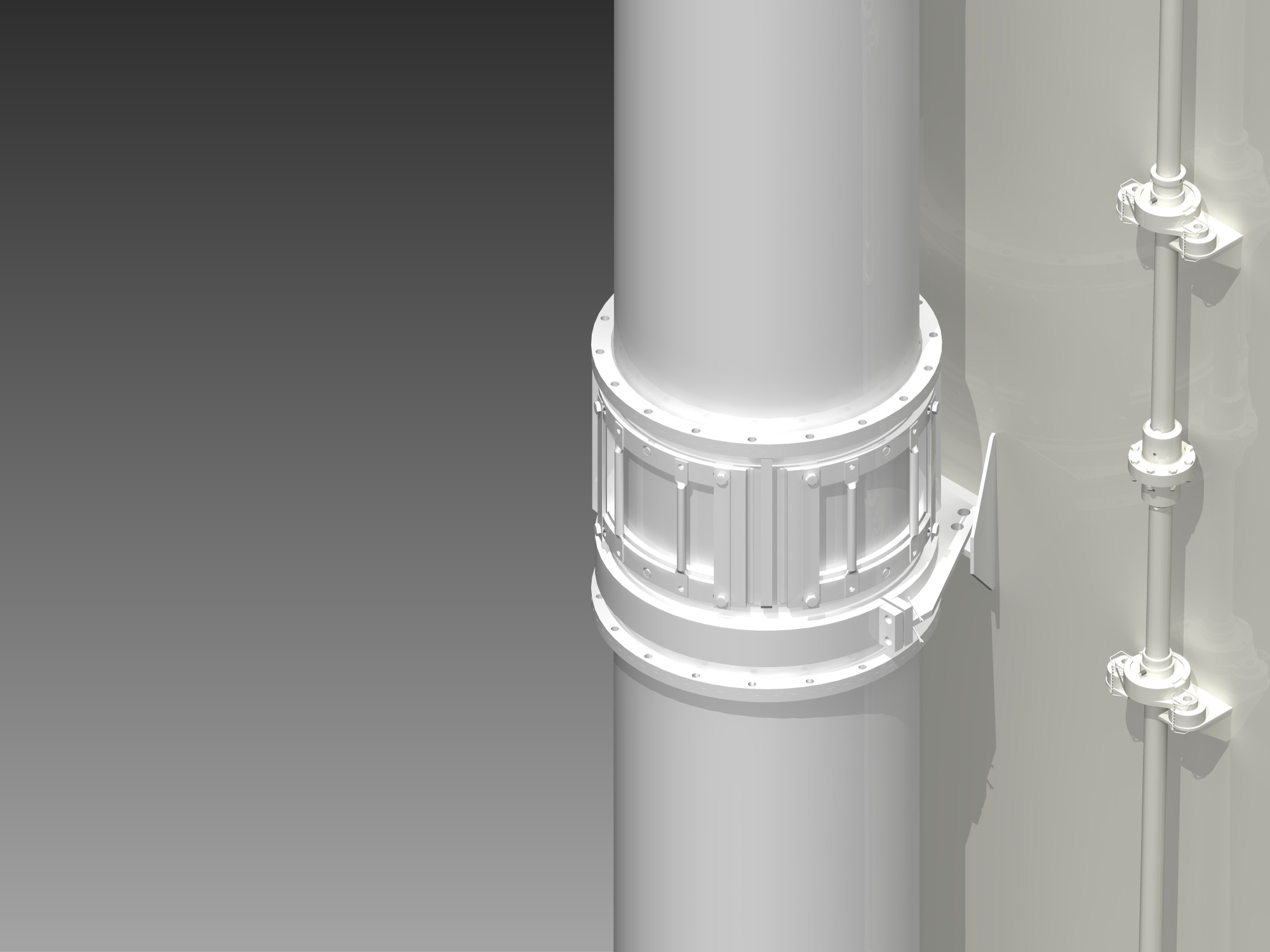

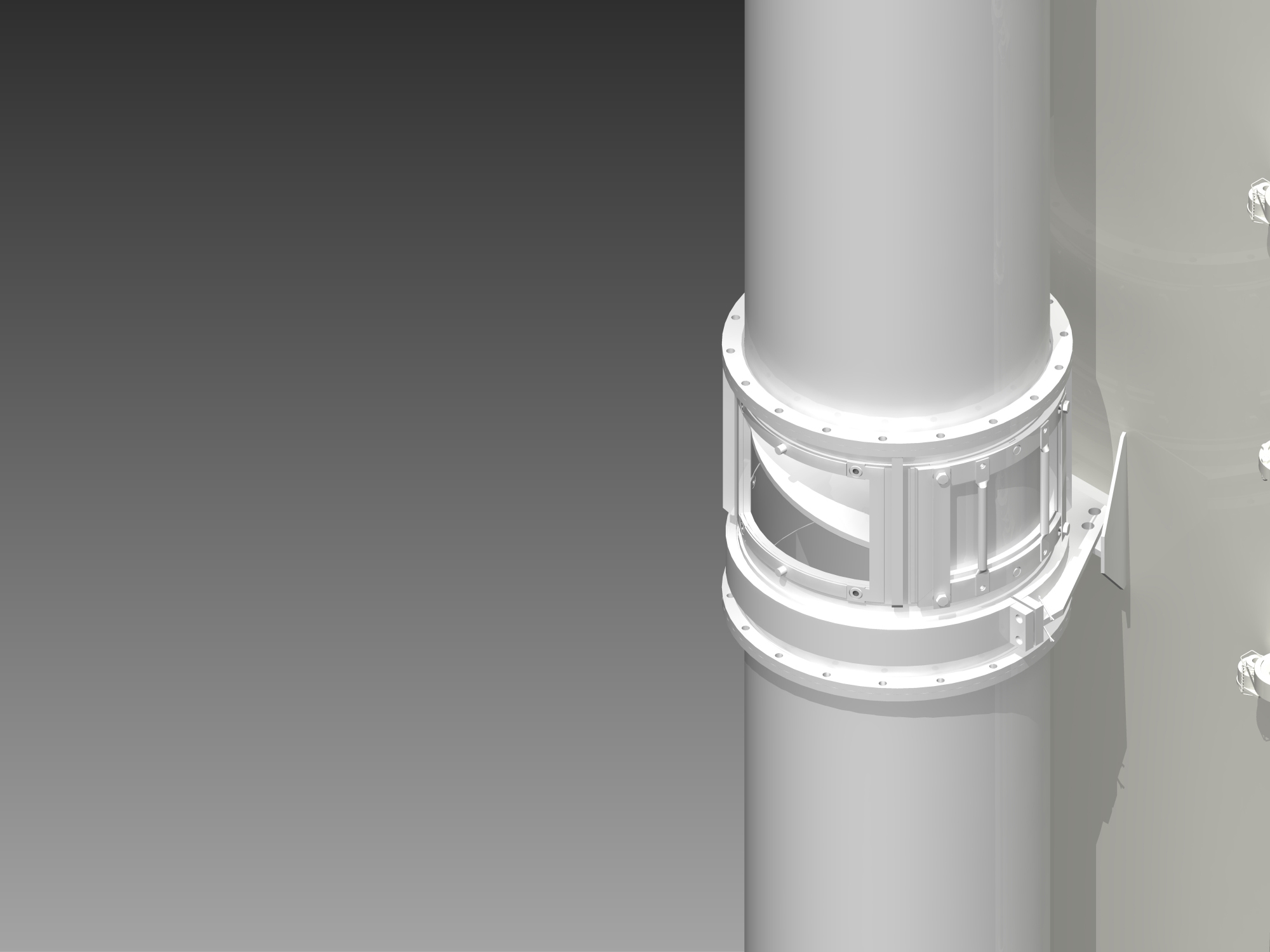

Intermediate bearing

Siwertell designed the unique Outer Diameter (OD) bearing to achieve a continuous screw flight for the vertical conveyor without any interruptions. A continuous screw reduces power consumption and minimizes the risk of material getting stuck in the tube.

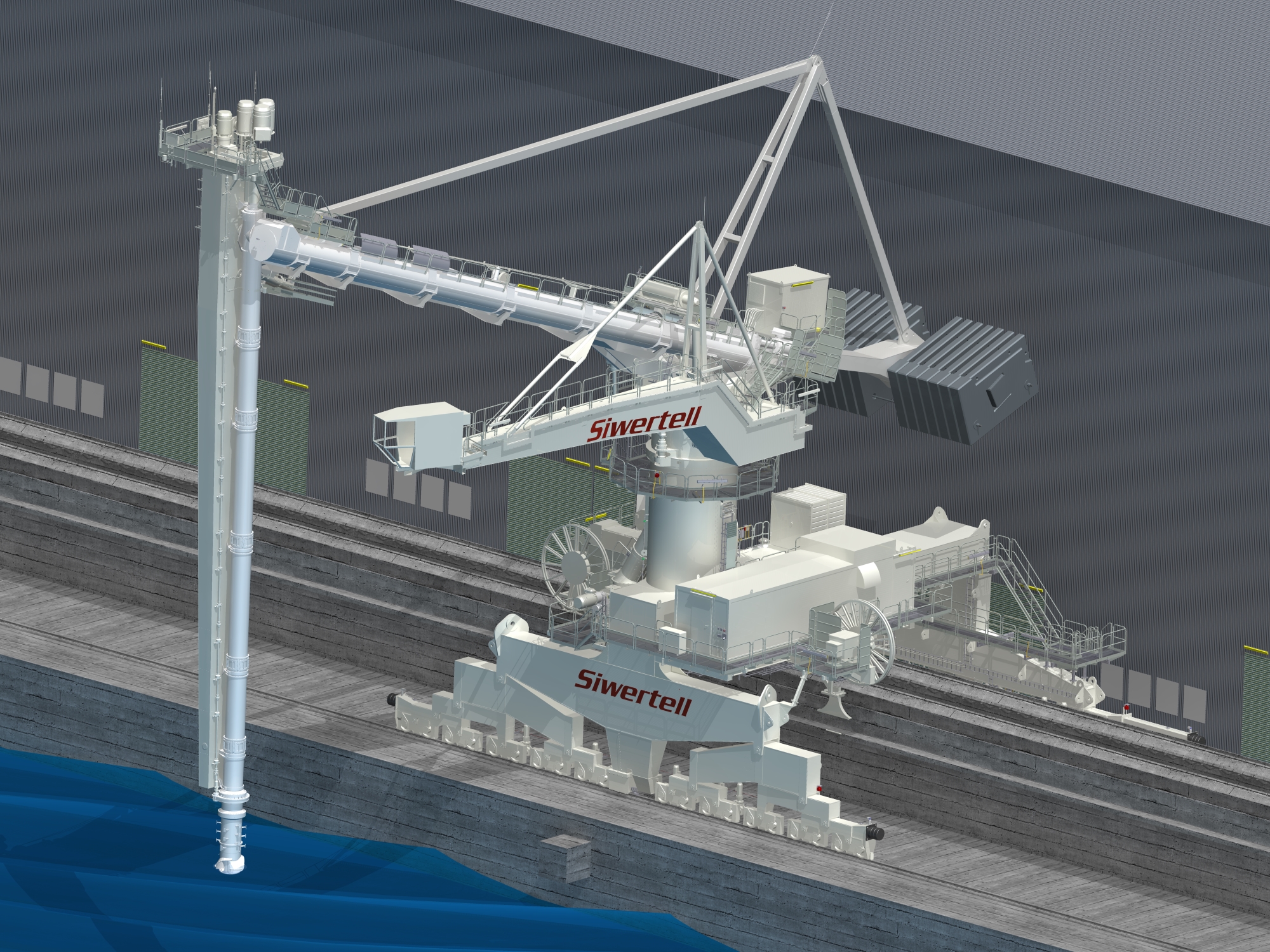

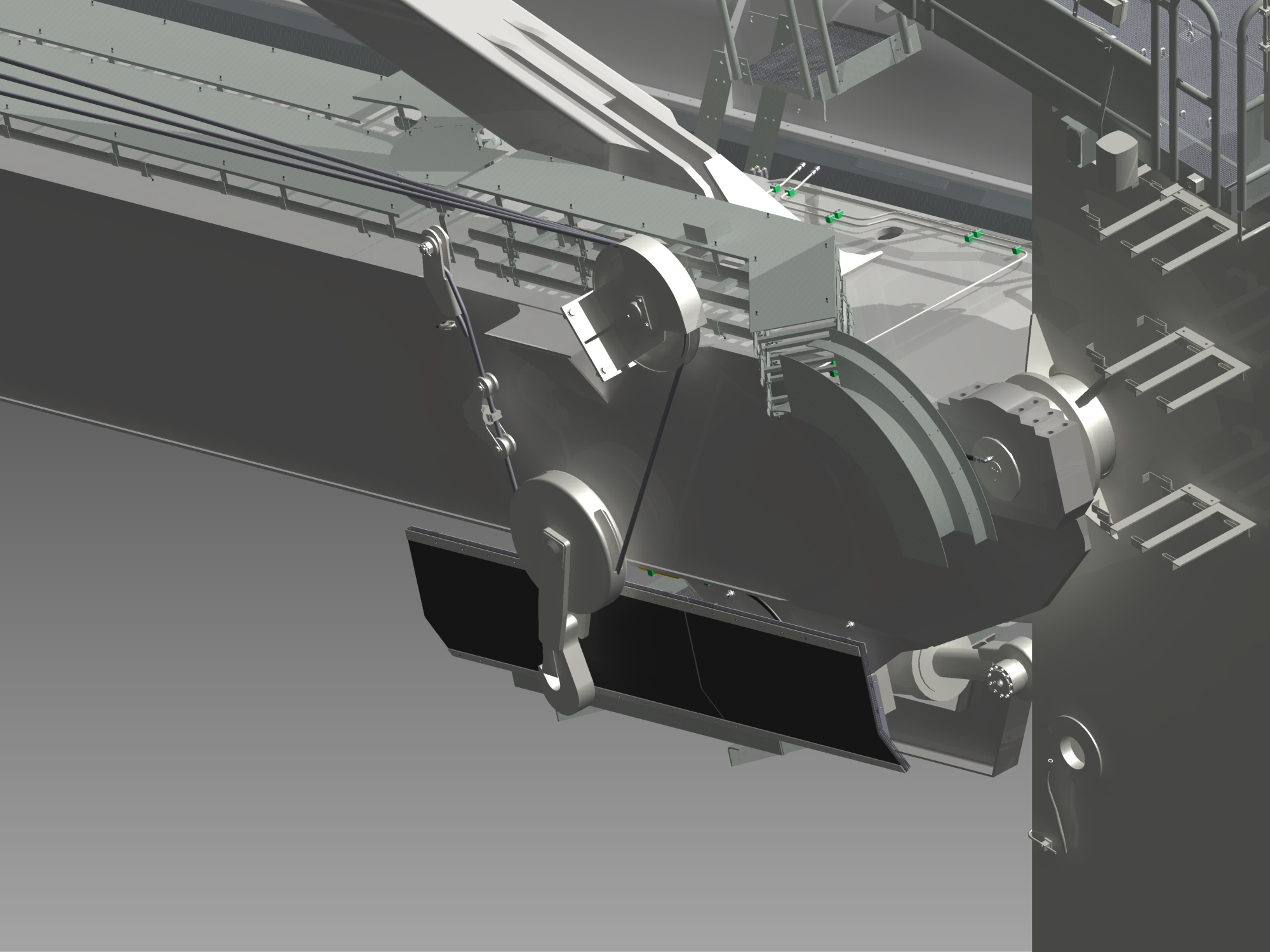

Auxiliary hoist

Heavy items such as pay loaders and excavators are often used in the holds to assist the unloader during the final clean-up phase. A wire rope hoist, installed on the horizontal arm, is used for lifting equipment in and out of the hold.

Horizontal conveyor

The horizontal conveyor is normally a screw-type conveyor. Mounted on the horizontal boom steel structure, it receives bulk material from the vertical conveyor via an enclosed transfer chute. It then transports material to a vertical discharge chute in the center of the slewing turret. For some applications an enclosed belt conveyor is used instead of a screw conveyor.

Electrical system

The electrical system is installed in an insulated electrical housing equipped with a heating fan and an air-conditioning unit. It is made up of elements such as low voltage switchboards with a motor control center, contactors, a programmable logical control-system and the human machine interface.

Operator's cabin

The unloader can be operated either from the cabin or using a remote control unit directly from the side of the ship’s hold. Both arrangements offer excellent views of the unloading area. The cabin is mounted on an arm at the same level as the horizontal arm and it slews along with the horizontal arm. It is fully-insulated and equipped with a heating fan and an air-conditioning unit to provide the operator with a comfortable work place, even in extreme weather conditions.

Bruks-Siwertell

Bruks-Siwertell