Safety

CE conformity

We are dedicated to the design and production of safe, reliable and high-quality bulk handling equipment for our customers. To achieve this, our road-mobile ship unloaders are designed and built in accordance with the European machinery directive.

Minimizing material handling risks

Several commodities such as sulfur, grain, some fertilizers and other organic material have the potential to self-ignite or explode, especially when contained, meaning that bulk handling systems must be able to mitigate these risks. In addition to this, they must also ensure minimal cargo degradation, not simply to preserve the quality of the shipment, but by minimizing and keeping dust creation low, fire and explosion risks are reduced.

Bruks Siwertell benefits from decades of sulfur-handling experience; a particularly hazardous material when enclosed. This has been used to develop safety systems, such as the Siwertell Sulfur Safety System (4S), for handling explosive materials, meeting CE conformity regulations and the latest ATEX directive relating to the control of explosive atmospheres.

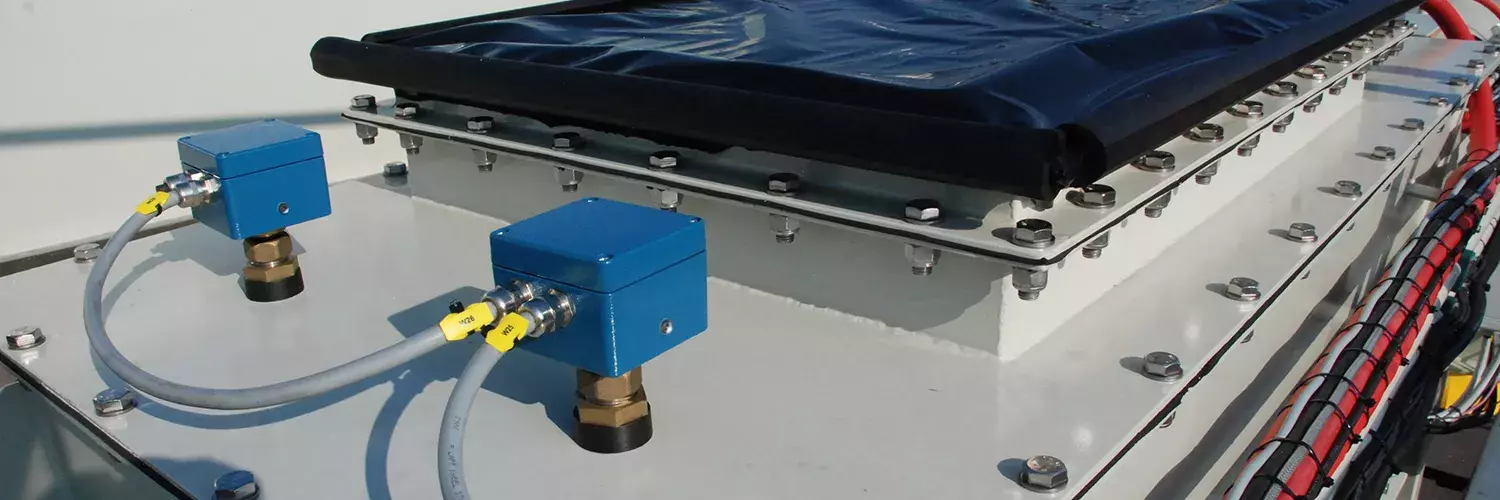

When handling a commodity that involves the risk of fire and explosions, our ship unloaders can be ATEX configured. The configuration means explosion venting devices, a spark-detecting system and, in some cases, fire-extinguishing systems, are installed to prevent fire spreading throughout the cargo and machine.

The reinforced conveyor system, together with the explosion venting devices, are built to handle the force of a possible explosion and control its release, without harming personnel or equipment.

Siwertell Sulfur Safety System (4S)

For operations that handle sulfur, our road-mobile unloaders are fitted with the Siwertell Sulfur Safety System (4S), enabling them to unload this material in a safe, reliable way, and also protect the environment from any spillage or dust emissions.

Bruks-Siwertell

Bruks-Siwertell