Siwertell screw-type loader ordered for dust-free dry bulk handling in the Caribbean

23 Jun 2021

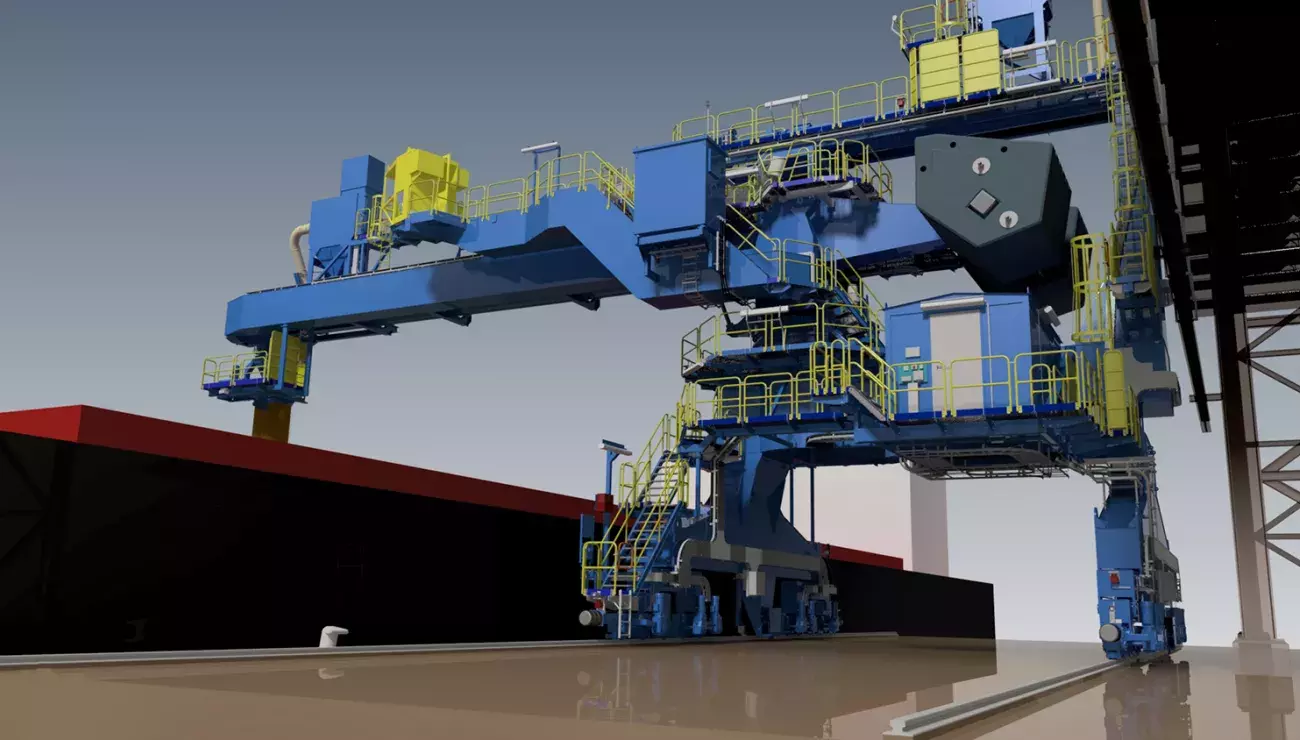

Bruks Siwertell has won a new contract to deliver a Siwertell screw-type ship loader for the totally enclosed, dust-free handling of cement and clinker. It will serve a new cement plant being built in the Caribbean and will provide a unique solution for a complex set of dry bulk material handling requirements.

“We are delighted to be working on this project and our expertise has been called upon from the start,” says Axel Dahl, Sales Manager, Bruks Siwertell. “It really has been a case of engineering experts coming together to solve a particularly complex set of operational and dry bulk material handling needs.

“This is our first Siwertell loader installation in this particular region and it will have to work in one of the most earthquake-prone zones of the world,” Dahl continues. “The cement industry in the area is currently undergoing some of its most advanced improvements in decades, and as part of this, environmental protection is very much under the magnifying glass.

“Some of the technical challenges that we had to consider for the contract included a new optimized conveying system for handling clinker,” he explains. “Clinker is a very abrasive material and wears down standard-designed components relatively quickly. In addition to this, as the project is heavily focused on the environment, any system that handled both clinker and powdery cement had to deliver dust-free handling. The obvious choice for us was to consider a conveying system with screw technology.

“The final design offers benefits to both the environment and the operator; a screw-type loader that delivers totally enclosed material conveying, preventing dust emissions and spillage, combined with the ability to withstand the abrasive effects of tougher dry bulks, like clinker, prolonging component wear and service life,” adds Dahl.

The type-1B ship loader will deliver cement and clinker handling at a continuous rated capacity of 600t/h, with a peak loading rate of 750t/h, for vessels up to 20,000 dwt. It will be delivered in 2021 and is scheduled to be operational later in the year.

Bruks-Siwertell

Bruks-Siwertell