New Bruks drum chipper ordered for leading US lumber operator

27 Jan 2025

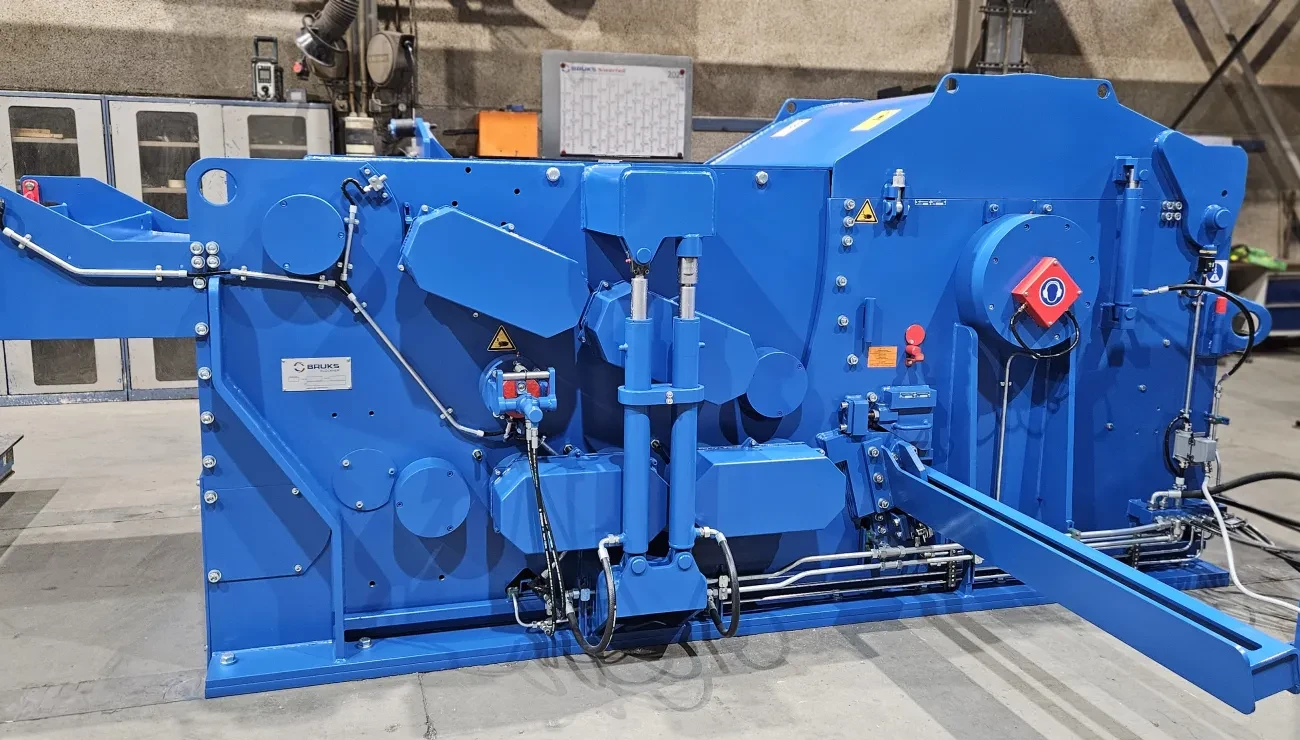

Bruks Siwertell has signed a contract with leading North America forest products company Sierra Pacific Industries (SPI) for the delivery of a customized Bruks drum chipper. The equipment has been ordered for a new cutting mill and state-of-the-art stud mill being built to replace SPI’s existing sawmilling operations in Eugene, Oregon. It will efficiently handle sawmill byproducts for onward use in SPI’s biomass energy cogeneration plant and for pulp and paper customers.

Third generation, family-owned SPI is one of the largest lumber producers in the US, operating eighteen sawmills in California, Oregon and Washington; all of which use advanced technology to maximize raw material use. The company is also the largest private US timberland owner and produces millwork, wood fiber products, windows, and renewable energy as well.

“High-performance, industrial wood chipping capabilities are essential in modern sawmills, and this order builds on a long-standing partnership,” notes Rafael Escamilla, Project Development Engineer, Bruks Siwertell.

“SPI has Bruks Siwertell equipment installed across many of its other facilities, and appreciates the quality, reliability and the ease of maintenance that Bruks drum chipping machines offer. Essentially, we deliver products that last and perform well under high-use, challenging conditions,” adds Escamilla.

SPI’s latest Bruks DH 400 (550) x 1000 drum chipper features custom-designed infeed rollers and supplier-specific gearboxes. “The machine has been tailored to meet SPI’s operational preferences,” explains Escamilla. “For example, the first two infeed rollers are segmented, which reduces overall maintenance.”

The Eugene Bruks drum chipper installation is planned for delivery mid-2025. It will process sawmill byproducts, including softwood trim blocks and offcuts, at a rated capacity of around 20t/h, helping SPI maximize efficiency and yields from its wood-processing operations.

Sustainability is key to SPI operations. As part of its sustainable forest management program, SPI plants about three seedlings for every tree it harvests. Earlier this year, the company celebrated planting its 300 millionth seedling.

For more information, please contact us

Senior VP, Sales & Marketing, Bruks Siwertell Inc.

Ken Upchurch

+17709056023

Bruks-Siwertell

Bruks-Siwertell