Hydraulic power unit

Hydraulic power unit

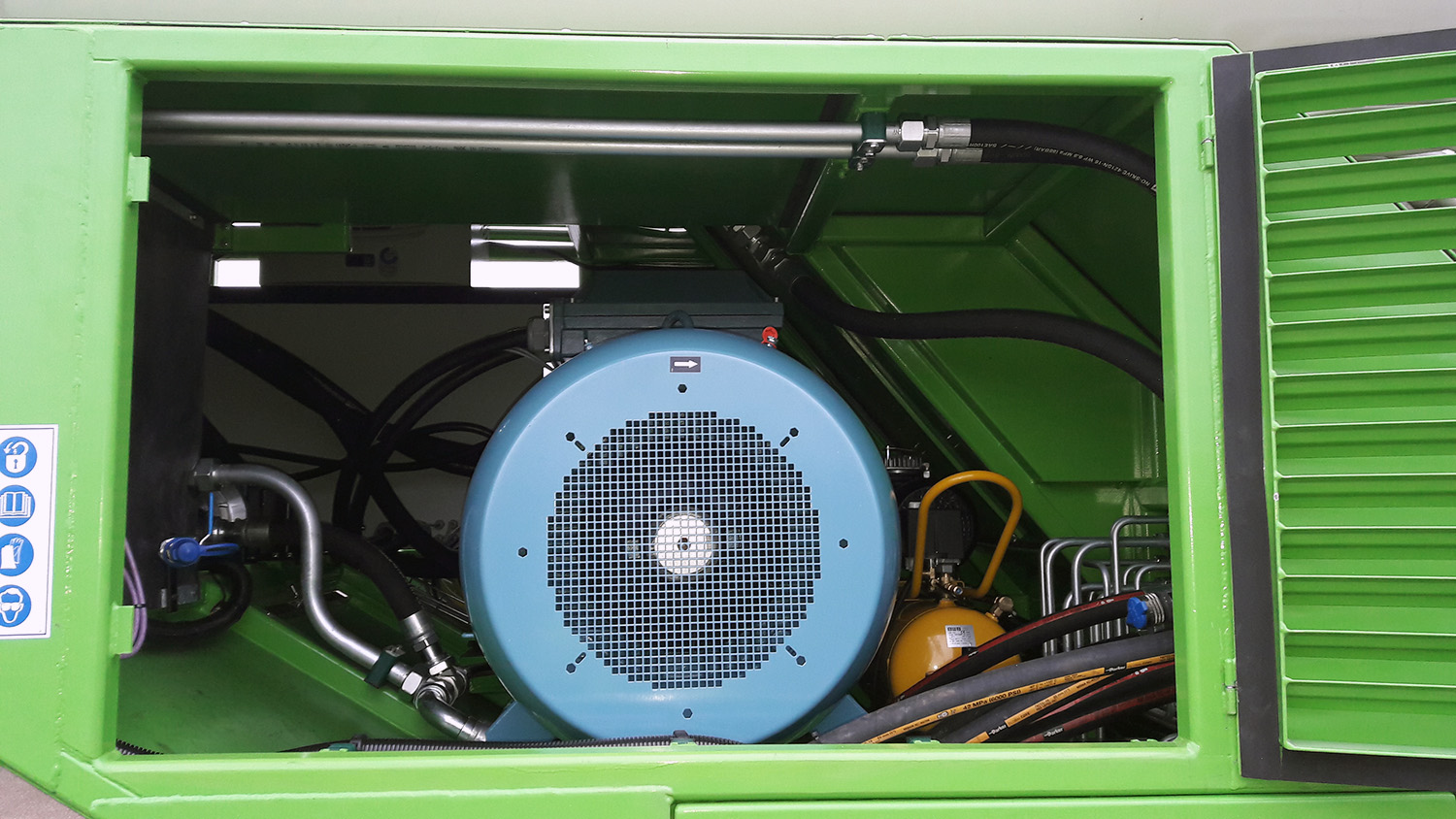

All drives and actuators are hydraulically-operated and provide the unloader’s movements. They are served from a hydraulic power unit; whose prime mover is either a diesel engine or an electric motor.

This internal hydraulic system consists of the oil reservoir, hydraulic pumps, proportional valves, directional valves, oil filters, pressure sensors, oil temperature sensor, oil level sensor and oil cooler.

External hydraulic system

The unloader’s external hydraulic system distributes hydraulic power to most functions on the equipment as a whole, both the unloader and trailer. The external hydraulic system consists of pipes, hoses, motors, cylinders and valves.

Optional power sources

Bruks Siwertell continually upgrades the diesel engine specification to meet the latest regulations on exhaust and noise emissions. Diesel-driven systems are often preferred, giving the operator complete independence from any infrastructure requirements. The electric motor alternative is available where the unit can be plugged into a permanent power connection at the intended port of operation. Electric motors are energy efficient and quiet.

Diesel engine options

The turbo-charged diesel engines have various installed power ratings depending on the unloader model. All varieties can be supplied emission-certified to the latest European Union (EU) and US Environmental Protection Agency (EPA) regulations. The mobile unloader can meet all emissions standards; engines are specified depending on the emission-standards required in the region that they will operate in.

When the highest emission standards are applied, the engine is equipped with a clean emissions module (CEM), which ensures the lowest possible emissions. The diesel exhaust fluid (DEF) additive, AdBlue, helps the system reduce NOx emissions in the exhaust gases.

Diesel engines are fuel-efficient, reducing operational costs and lowering environmental impact. Operating a diesel-powered road-mobile ship unloader enables operation at virtually any port or quay without having to depend on a local power grid.

Extensive warranty programs, and product support through diesel engine manufacturers’ extensive global dealer and worldwide service and maintenance networks, ensures reliable, long-term operation with minimal downtime.

Speed-controlled cooling fans

The automatic control of the unloader’s cooling fans, which are installed throughout the equipment, is another energy saver. This function enables fan speeds to be perfectly matched to requirements, so that just enough energy is used to effectively cool the equipment. This not only saves energy, but dramatically reduces sound emissions as well.

Bruks-Siwertell

Bruks-Siwertell