Digital hatch visualizations improve situational awareness, efficiency and safety

With new advances in digitalization, it is possible to offer safer, faster and more efficient dry bulk handling operations. Bruks Siwertell’s growing portfolio of digital solutions include anti-collision systems, semi-automatic unloading, and the ability to create digital hatch visualizations, providing real-time 3D representations of the ship’s hatch cover opening, hold and cargo surface.

The option for digital hatch visualization is made possible with the use of an anti-collision system that uses technology from a third-party company.

DESCRIPTION

Hatch visualizations are dependent on the use of technology. Even in challenging environmental conditions such as dust, fog, and snow, we can provide a very effective mechanism for digital image generation.

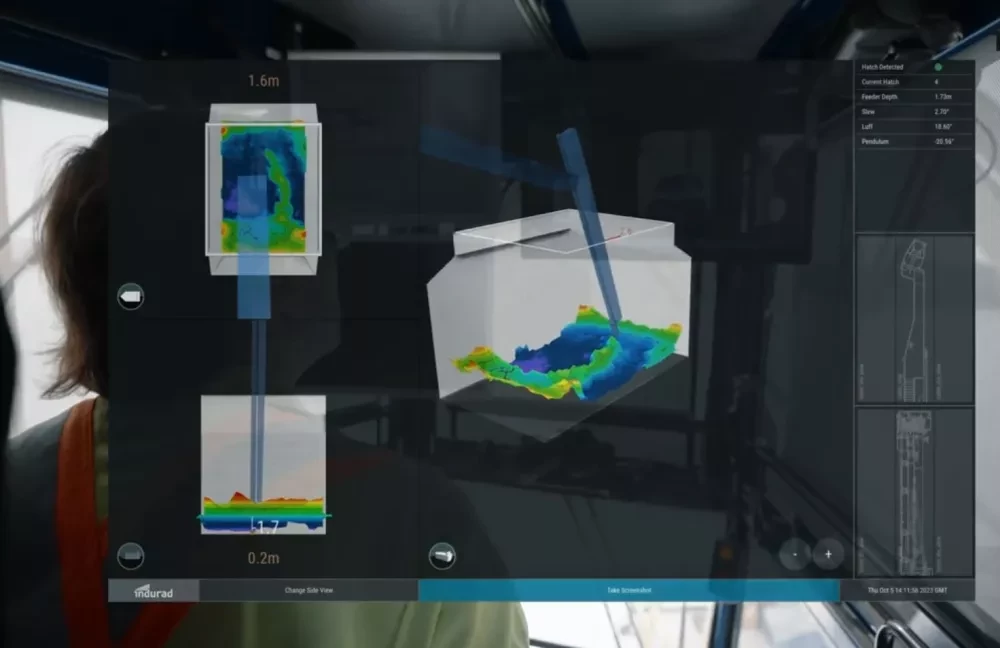

With the hatch visualization option, operators can see the distances in meters to the hatch coaming and depth of the material in the hold, making it much easier for the operator if running in either manual or semi-automatic mode.

Digital hatch visualization shows a 3D model of the hatch area, which is displayed on a full-color monitor in the operator’s cabin. The operator can see a digital representation of the hatch and the material inside. A top view, side view and an overall view are available.

BENEFITS

Digital hatch visualizations offer a number of benefits. These include:

- improved operational overview of the ship’s hold and immediate vicinity around the dry bulk handling equipment

- increased safety

- reduction in the potential for damage and collisions

- improved operational efficiency

- improved cargo throughput

- increased jetty utilization rates

- improved profitability

Bruks-Siwertell

Bruks-Siwertell