Service - USA

Electrical upgrade delivers performance boost to US cement unloader

Leading American cement company, Ash Grove, has operated a Siwertell ship unloader since 1982 in Duluth, Minnesota. To maintain its dry bulk handling performance and keep up with current cement demands, the unloader needed an electrical upgrade. The company turned to Bruks Siwertell for help.

Customer need

Ash Grove operates 12 cement plants and 43 terminals located throughout the Midwest, Texas, and Western United States (US). In 2019, it became one of the largest cement producers in North America with the addition of operations in Florida, the US Great Lakes, and Canada.

One of Ash Grove’s US Great Lakes’ locations is the port city of Duluth, located on Lake Superior in Minnesota. Since 1982, it has been served by a rail-mounted ST 440-C screw-type Siwertell ship unloader. The unit offers high through-ship efficiencies and a continuous rated cement handling capacity of 600t/h, discharging vessels up to 32,000 dwt.

To keep up with current cement demands in the port, the unloader needed to be in peak condition, but, after over forty years in operation, its old electrical relay system and many of the system’s parts were no longer manufactured.

Ash Grove takes a proactive approach to service and maintenance, and over four decades has enlisted Bruks Siwertell’s expert service support for various tasks, and this was no exception.

Our solution

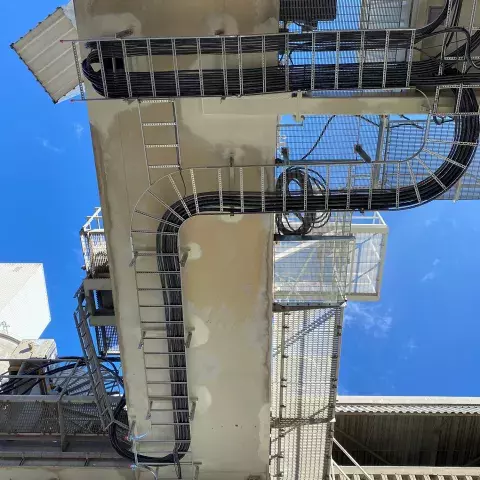

Following an inspection and owner discussions, it was decided that the long-serving ship unloader should have a new electrical housing that met today’s performance standards. Complementing this upgrade, a new human machine interface (HMI) with touchscreen was specified as well. This offers improved visual information, giving operator’s better control and an enhanced overview of unloading operations and performance.

Ash Grove’s port equipment has a high utilization rate and because vessels have booked slot times through all locks crossing the Great Lakes, the operator has to meet very precise port arrival and departure schedules. As a result, all maintenance work has to be planned and organized well in advance, minimizing downtime and disruption to scheduling.

To accommodate this, the upgrade work, completed in 2022, was carried out over a three-week timeframe in three phases. This ensured that Ash Grove could use the unloader during the project, which also included fitting modern variable frequency drives (VFDs) to improve control of the unloader’s movements. VFDs are very efficient and offer stepless speed control. In addition, the inlet feeder gear and electric motor were updated from direct current (DC) operation to alternating current (AC) with VFD-control.

Once complete, the upgraded unloader was commissioned, with the first vessel discharged under Bruks Siwertell’s supervision.

For more information, please contact us

- Service

- Cement

Customer

Ash Grove

Service type

Electrical upgrade

Bruks-Siwertell

Bruks-Siwertell