Service - Nigeria

Service - Nigeria

Expert service keeps critical port in peak condition

At Apapa Port, Lagos, Flour Mills of Nigeria PLC depends on Bruks Siwertell technology to keep grain handling operations reliable and efficient. When modernizations, from complex screw conveyor installations through to advanced PLC upgrades were needed, Bruks Siwertell expert original equipment manufacturer (OEM) service support stepped in.

CUSTOMER NEED

Flour Mills of Nigeria PLC, one of the country’s leading grain importers, operates two rail-mounted Siwertell ST 490-M screw-type ship unloaders, delivered in 2001 and 2007, and a jetty belt conveyor system, at the busy Apapa Port in Lagos. The unloaders handle vital food commodities including wheat, maize, soya, and barley, ensuring a steady flow of grain into the country.

With equipment running continuously during ship unloading operations, Flour Mills of Nigeria requires service support that safeguards operational reliability, maximizes unloading efficiency, and minimizes disruption during critical cargo-handling windows. In line with these requirements, the operator has a long history of service support from Bruks Siwertell, minimizing downtime through strategic maintenance.

In 2025, Flour Mills of Nigeria needed expert assistance for several key maintenance projects for its Siwertell screw-type ship unloading system: the installation of a new horizontal conveyor; alignment of vertical conveyor components; and electrical system upgrades including the replacement of a programmable logic controller (PLC) and frequency converter.

Tight operational schedules, high volumes of cargo, and environmental conditions demanded that these tasks be completed with precision and within agreed timelines. Beyond technical support, the operator also needed trusted service guidance on preventive maintenance, spare parts planning, and best practices to ensure that the unloaders continue to deliver safe, reliable, and cost-efficient performance in the long term.

OUR SOLUTION

Bruks Siwertell’s service team delivered a comprehensive program of mechanical and electrical support at Apapa Port, working in close cooperation with Flour Mills of Nigeria.

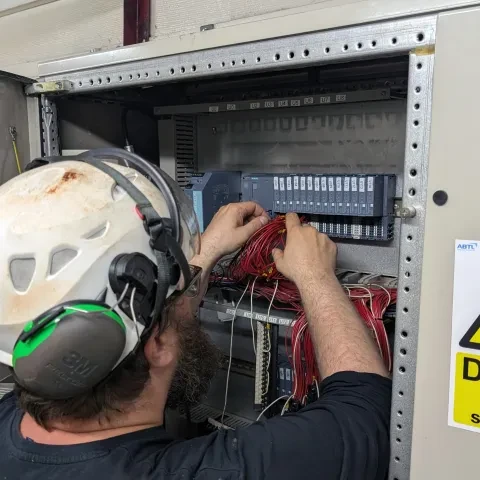

The delivery scope was a continuation of modernization work carried out in 2019, which included a PLC upgrade on one of the operator’s Siwertell ship unloaders (CSU 2) and the installation of a new frequency converter on its other Siwertell ship unloader (CSU 1). The new project included an electrical system upgrade with PLC programming on CSU 1. In addition, a new horizontal conveyor was installed on CSU 2, along with carrying out the precision alignment of its vertical conveyor system and a frequency converter replacement.

Bruks Siwertell’s expert engineers ensured that the complex lifting and assembly operations were safely managed, using mobile cranes to install major components in preassembled sections wherever possible. Careful on-site adjustments and alignment work were carried out to secure smooth screw conveyor operation, while preventive recommendations were provided to optimize long-term equipment performance.

On the electrical side, PLC programming and drive integration were carried out to deliver reliable control, with thorough testing before handover. The service visit also included detailed inspections outside the immediate scope of work, helping identify wear patterns and offering strategic spare parts advice. This proactive approach ensures Flour Mills of Nigeria continues to benefit from reliable, energy-efficient grain handling with minimal downtime and a clear roadmap for future maintenance.

For more information, please contact us

- Service

- Multimaterial

- Grain

Customer

Flour Mills of Nigeria PLC

Additional facts

Unloader model

2 x ST 490-M, rail-mounted

Unloading capacity

600t/h grain

Maximum ship size

75,000 dwt (32.3m beam)

Total weight

394t

Bruks-Siwertell

Bruks-Siwertell