Collaboration and initiative underpin plastic waste recycling success

- Sustainability initiative

Sustainability goal: environmental

Bruks Siwertell’s Oregon-based engineering and manufacturing company, West Salem Machinery (WSM), strengthens the Group’s agricultural and wood waste residue handling and processing capabilities, and enables the Group to better serve the bioenergy and biomass markets.

Bruks Siwertell Group has a measurable goal of achieving zero waste across all office and production units by 2030. Reducing the amount of waste, managing waste correctly and seeking circular solutions are important strategies in reducing the overall environmental impact of business operations.

By identifying recyclable materials and ensuring they are correctly handled, landfill volumes can be lowered, environmental impact is reduced, and personnel engagement in sustainability practices can be strengthened.

Solution and results

This year, to encourage collective responsibility and drive measurable waste-reduction initiatives, WSM is running a campaign that is inspiring personnel to notice and suggest ideas for waste recycling, even rewarding people with a gift card for every approved idea.

“At WSM, belonging is more than just a slogan; it is our mindset,” says newly appointed Sustainability Coordinator, WSM, Martinus Susantoputra. “We have a legacy of plastic waste reduction at the company and efforts by individuals are often commended and ideas are listened to.”

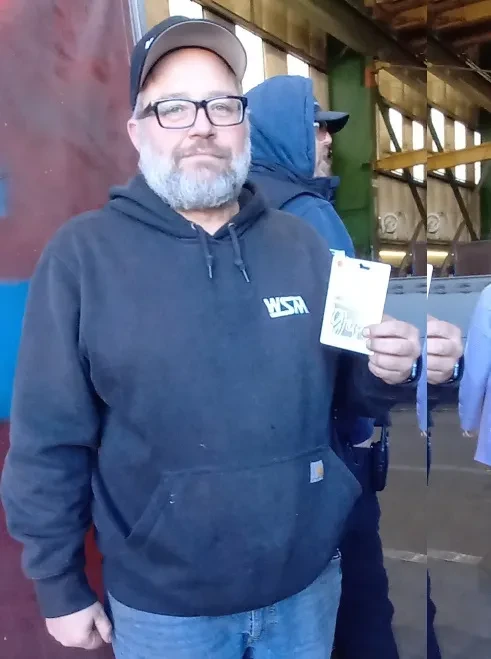

One such idea came from Tony Williams, Material Handler, WSM. He noticed how much plastic wrap from incoming materials was being discarded each day. “I would see the 90-gallon garbage bin fill up every single day with plastic wrap, destined for landfill,” Williams explains. “It got me thinking that there has to be a better way; we should be able to recycle this.”

Williams raised this thought with Linda Dunphy, Purchasing and Planning Manager, who looked for immediate solutions with Martinus Susantoputra. “This observation was exactly the kind of proactive thinking we want to encourage,” says Dunphy. “It showed that sustainability thinking is not just a corporate goal, it is something that we can all influence directly.”

A solution was decided together. Dedicated collection points were established across the facility to separate recyclable plastic wrap from other waste streams. “Our first step was simple, make it easy for everyone to do the right thing,” Susantoputra notes. “Within weeks, we saw a visible reduction in our landfill waste, and personnel took pride in contributing to the change.”

The second step, working with local partners to ensure proper processing, was more of a challenge. The appointed waste hauler was unable to treat the plastic wrap as recyclable, despite its recyclability, and local regulations prevented WSM switching to another hauler. Most regional plastic brokers declined to pick up the material because it lacked a profitable resale chain. A few brokers were willing to collect a full container load, but space constraints at WSM made that impossible.

To address this, Susantoputra explored options for installing a waste compactor or baler to reduce storage volume. However, the cost of purchasing or renting suitable equipment was too high for the pilot phase.

The breakthrough came with a call to Agri-Plas Inc, a family-owned recycling company specializing in agricultural plastic waste. “When we learned what Agri-Plas could offer, it felt like the missing piece,” says Susantoputra. “The company not only accepted our plastic wrap free of charge, but also offered to take most other types of plastic, provided they were clean and sorted.”

Agri-Plas processes incoming materials by shredding, heat-treating, and grinding them into pellets, which are then sold to both local and international customers for reintroduction into new production cycles. Beyond conventional recycling, Agri-Plas has also developed an innovative process to extract synthetic crude oil from waste plastics, a promising step toward circular resource recovery. The company is currently scaling this technology to meet growing industrial demand.

Through this partnership, WSM now ensures that its recyclable plastic wrap avoids landfill entirely. “This collaboration has shown us that even when the system seems limiting, creative thinking and local partnerships can make true sustainability possible,” concludes Susantoputra.

The result is a significant decrease in plastic waste sent to landfill and a noticeable shift in workplace culture. Personnel are more conscientious about sorting materials correctly, and the system has become a model for future waste-reduction efforts.

Monitoring and assessing sustainability milestones and achievements

Bruks Siwertell Group’s sustainability goals are assessed from an environmental, social, and governance (ESG) perspective, with each initiative falling into one or more of these categories. This is to clarify how different initiatives impact our overall sustainability work, and how their results can be used to maximum effect. It also contributes to our commitment to transparency. All aspects of our sustainability work are designed to be educational, so that we increase our knowledge and adjust our ambitions accordingly.

Bruks-Siwertell

Bruks-Siwertell