Next-generation service agreements, tailored to meet your needs

8 May 2024Service is pivotal to Bruks Siwertell, with support offered through on demand, emergency, and effective, planned maintenance, tailored to suit. This ensures that customers and operators have access to original equipment manufacturer (OEM) expertise, for the lifetime of their equipment.

Like technological developments within the company, service provision is continually being developed as well. In line with this approach, a new type of service agreement has recently been launched for use across the entire range of Siwertell ship unloaders and loaders operating in all dry bulk industry segments.

However well dry bulk handling equipment is designed, manufactured, installed, and commissioned, it inevitably faces a long and demanding operational life. The cost of maintenance represents a fraction of the overall investment and operating costs, and unexpected downtime and emergency support is almost always more expensive than a planned strategy.

It is widely accepted that good maintenance practices positively support business operations, and part of Bruks Siwertell’s job is helping operators with their maintenance strategies. “Our service agreements for bulk handling equipment allow an operator to focus on their core business, while benefiting from maintenance budget predictability, effective planning and scheduling, lower service costs and peace of mind, resting in the knowledge that an OEM expert will be on hand if needed,” says Daniel Frostberg, Service Director, Bruks Siwertell.

Tailored to suit

“Our newly introduced next-generation service agreements allow customers and partners to tailor and customize their desired levels of service support. With this stackable approach, we can offer tailored solutions that allow operators to choose exactly what they need,” Frostberg continues.

“We all know that economizing on maintenance-related activities, buying non-OEM parts, or deferring work does not represent value, because it invariably costs an operator more in the long run, and has the potential to cause reputational damage. Furthermore, operators are not able to benefit from the financial gains of equipment availability and optimized performance.

“This is why we strongly recommend a planned maintenance approach through our service agreements, allowing customers to know, in advance, the schedule and costs of maintaining their dry bulk handling equipment for a three-year period,” he explains.

Customers know their dry bulk handling equipment, and can see, and often hear and assess how it is performing. With fifty years of leading the market in dry bulk handling, Bruks Siwertell can add to this expertise.

OEMs are able to rapidly assess equipment and determine its condition, which ensures that parts are not replaced unnecessarily. They can also devise the most cost-effective strategy for repair and renewal. OEM surveyors can make relatively small adjustments to operational parameters that deliver significant performance benefits.

The closer the better

Close customer relations are a critically important part of service support. “Our service teams are the interface between the customer and our company, and continuously work for it to remain so, often for decades after equipment has been delivered,” says Frostberg. “The closer this relationship is, the better. Customers put their trust in us, and we need to honour this. Our commitment to continuous development work, including the addition of new services, like our next-generation service agreements, which are designed to respond and match customers’ needs, act as a platform for this.”

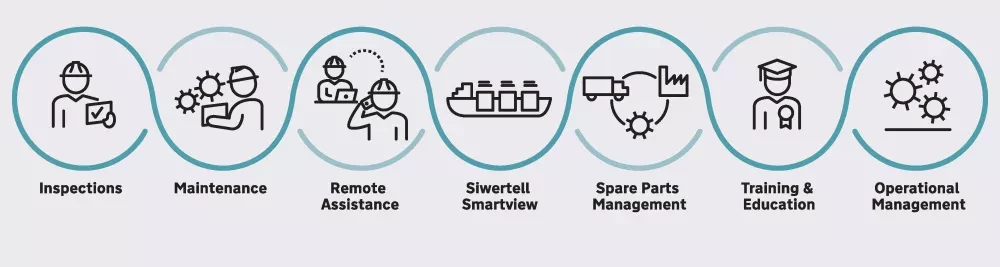

Planned service contracts comprise a number of different areas of support and many of these can now be customized, tailored and combined for optimal operational and maintenance strategies. Agreements include, for example, different types of inspections that cover mechanical, electrical and structural components of the equipment.

Importance of inspections

During a mechanical inspection on a ship unloader, for example, all essential unloader functions and movements are tested, along with sequences for the conveyor system. A review of any maintenance undertaken by the operator and the alarm history is also carried out, as well as an analysis of recurring alarms and trends.

When inspecting dry bulk handling equipment’s electrical system and instrumentation, everything is checked including motors, electrical power and signal supply, the radio system, cables, and sensors. A test run during operations is also conducted to assess limit switches and carry out a visual and sound condition check of the main drives.

For structural inspections, a surveyor will carry out a visual assessment of the steel structure, with a detailed focus on stress-exposed areas. Any sections that have suspected damage can be checked using a dye penetrant. If further non-destructive testing is required, such as ultrasonic techniques and magnetic particle tests, Bruks Siwertell will arrange for additional specialist involvement. This might include testing weld joints, outer and inner hinge shafts, and the luffing and pendulum hydraulic cylinder attachments.

All inspections include dialogue between the surveyor and the customer, machine performance evaluation of unloading capacity, availability, downtime, and previous maintenance work from logged historical data.

After each inspection, a report is issued, including any upcoming work recommendations and areas that need further investigation. Inspections are a crucial element of the maintenance toolbox. They are always carried out on site and can be before, during or after other maintenance work.

The main purpose of an inspection is condition monitoring, identifying any irregularities and problem areas, and potential improvements of asset operation. They can also include wear part lifetime estimates and a spare parts inventory check and recommendation. Potential training opportunities can also come to light.

All inspections include dialogue between the surveyor and the customer, machine performance evaluation of unloading capacity, availability, downtime, and previous maintenance work from logged historical data.

After each inspection, a report is issued, including any upcoming work recommendations and areas that need further investigation. Inspections are a crucial element of the maintenance toolbox. They are always carried out on site and can be before, during or after other maintenance work.

The main purpose of an inspection is condition monitoring, identifying any irregularities and problem areas, and potential improvements of asset operation. They can also include wear part lifetime estimates and a spare parts inventory check and recommendation. Potential training opportunities can also come to light.

Digital connectivity

In addition to physical on-site support, Bruks Siwertell also offers remote support, giving customers access to a global network of dry bulk handling experts and specialists, who provide problem-solving suggestions and guidance.

Experts are available via a number of methods from phone to video calls; communication preferences are selected by the customer, so that the right approach is chosen for the operation. Planned for launch next year, Bruks Siwertell is also able to directly connect with the equipment’s programmable logic controller (PLC), for easy troubleshooting. This approach requires the dry bulk handling equipment to be connected via ethernet.

“When we are needed on site, we are there, but with the rapid and growing introduction of new technologies, we are able to help operators capitalize on the advantages of digitalization and remote diagnostics and support,” Frostberg says.

Included in this approach is Siwertell Smartview, also scheduled for launch in 2024. It is a cloud-based industrial Internet of things (IIoT) system, planned for phased integration into Siwertell dry bulk handling technology. The tool can monitor real-time operational parameters such as tons of material handled, average capacity, tons of material remaining in the vessel’s holds during unloading, and the overall duration of operations. This information is accessed through a personal computer (PC), tablet or smartphone, available in your hands any time of day, everywhere.

To enhance operational awareness, Siwertell Smartview can generate numerous different reports, so that operators are able to make the most of any information gathered, including operational performance data, individual vessel reports, and details about equipment availability, highlighting any downtime. Component-level data collection and historical performance are also possible with equipment IIoT-enabled with Siwertell Smartview.

Whole terminals to nuts-and-bolts

It is also important not to forget the basics. As well as terminal-wide performance overviews, other features of planned service contracts include inventory and spare parts management. Bruks Siwertell can take full responsibility for the entire process of managing and maintaining an organization’s spare parts inventory, ensuring that the right parts are available at the right time and in the right quantities. This also ensures that operators are relieved of the responsibility of having capital tied up in spare parts and warehousing.

In addition, planning and scheduling of essential service work and preventative maintenance strategies can also be carried out as part of a planned service agreement, along with training opportunities.

“We have many references for planned service agreements and examples of very carefully scheduled work that is precision-timed to suit an operator’s demanding dry bulk schedule. For example, in the grain handling industry, where maintenance windows are only available once a year,” he highlights.

“Customers are at the heart of our business and we work hard to ensure that we deliver on our promises, and if possible, exceed them,” says Frostberg. “A key part of this is ensuring that we offer global through-life customer support, so when we are needed, we respond. This responsiveness is now enhanced through our latest planned service agreements; ensuring that customers continue to benefit from our expertise.”

PLEASE CONTACT US FOR MORE INFORMATION

Bruks-Siwertell

Bruks-Siwertell